Turfgrass

Well-Known Member

My grain to glass procedures have improved greatly over the last six months. Finally I broke down and upgraded from a carboy to a conical fermenter. Currently fermenting in the conical is a NE IPA. While fermentation is happening, I need to assemble a few transfer hoses for a closed loop transfer that is oxygen free.

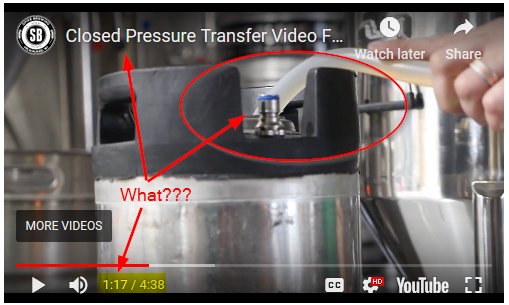

I have the hose that connects the co2 tank to the gas manifold of the conical figured out. I now need to assemble the conical to keg hose. It will start at the 1.5” tc port of conical, but I’m stuck on how to construct the rest. I know it will end with a beer out connection at the keg. I do have quick connect tc fitting (pictured) that I’d like to use along with 1/2” I.d. tubing. Any suggestions on how to bush down .5” id tubing to a keg quick connect?

Thanks as always.