After paying $100 for a crappy weld job from a "professional", I decided to have a buddy tackle the job instead. The "professional" did an OK job...he sort of back purged, and almost got the fittings on straight. There was a very minimal amount of sugaring. However, check out the work a good friend of mine did. His services are also for hire if anyone in the Denver area is looking for an awesome TIG welder.

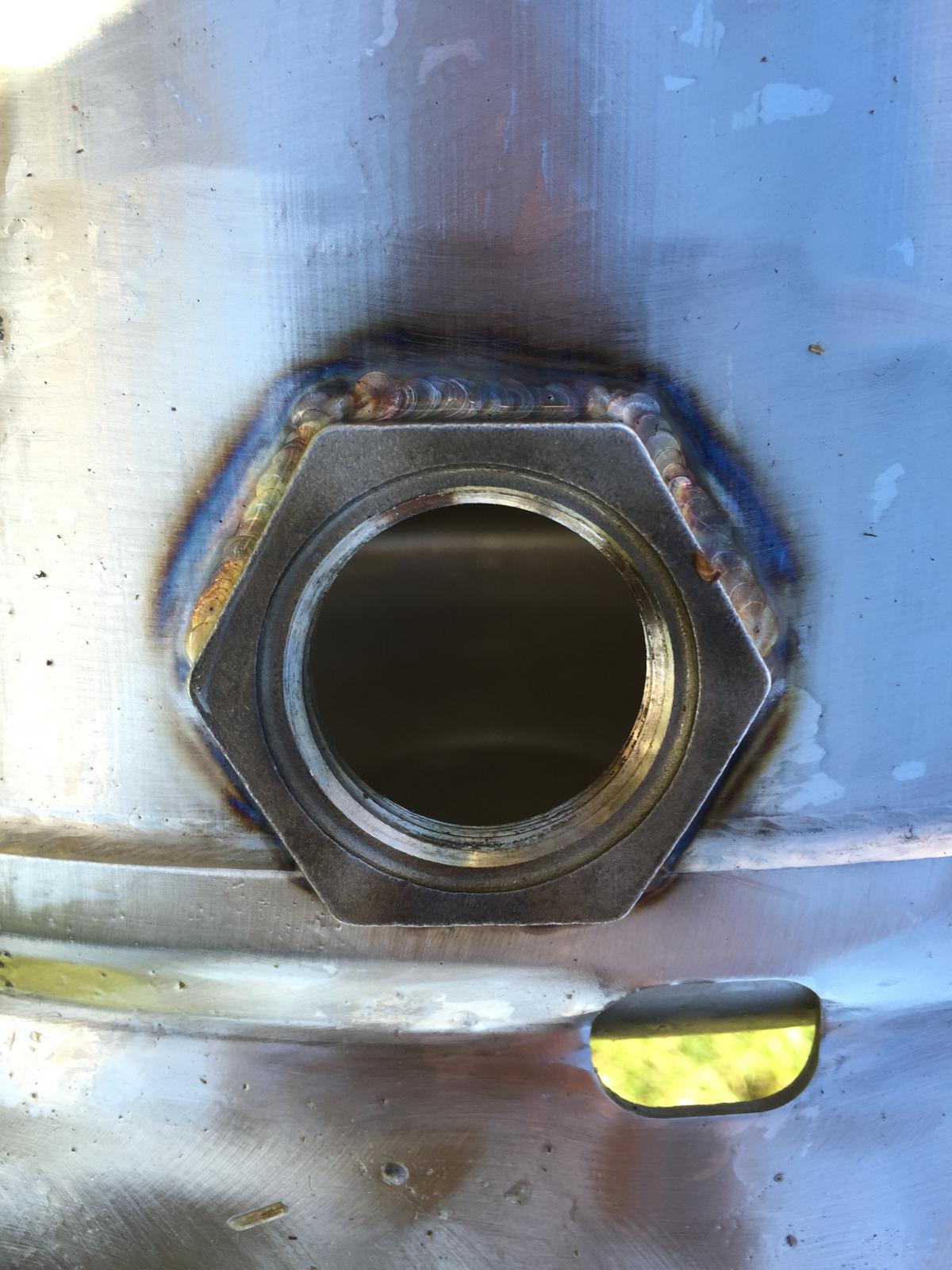

The first set of pics is the fittings as welded, before any cleaning. Also, the only reason the 1" nut weld has some corrosion and discoloring is because the purge setup fell due to the heat softening up the adhesive on the glue. We noticed after the welds were finished. The subsequent welds we made sure it stayed securely in place.

The first set of pics is the fittings as welded, before any cleaning. Also, the only reason the 1" nut weld has some corrosion and discoloring is because the purge setup fell due to the heat softening up the adhesive on the glue. We noticed after the welds were finished. The subsequent welds we made sure it stayed securely in place.