I've had this idea nagging me for a little while now, I wanted to see what you guys think:

Normally when we talk about going electric 240v this involves hundreds of dollars to into the thousands in sexy lit up control panels with ever expanding automation and electronics and gadgets and the list goes on...

In the spirit of BIAB, what about a system with the power of 240v but with the simplicity of stove top brewing?

All you really need to do is to safely provide 240 v to a heating element in a pot, and have a knob (just like a stove) to turn the heat up and down. An SSVR with a rheostat. This can be done really super cheaply.

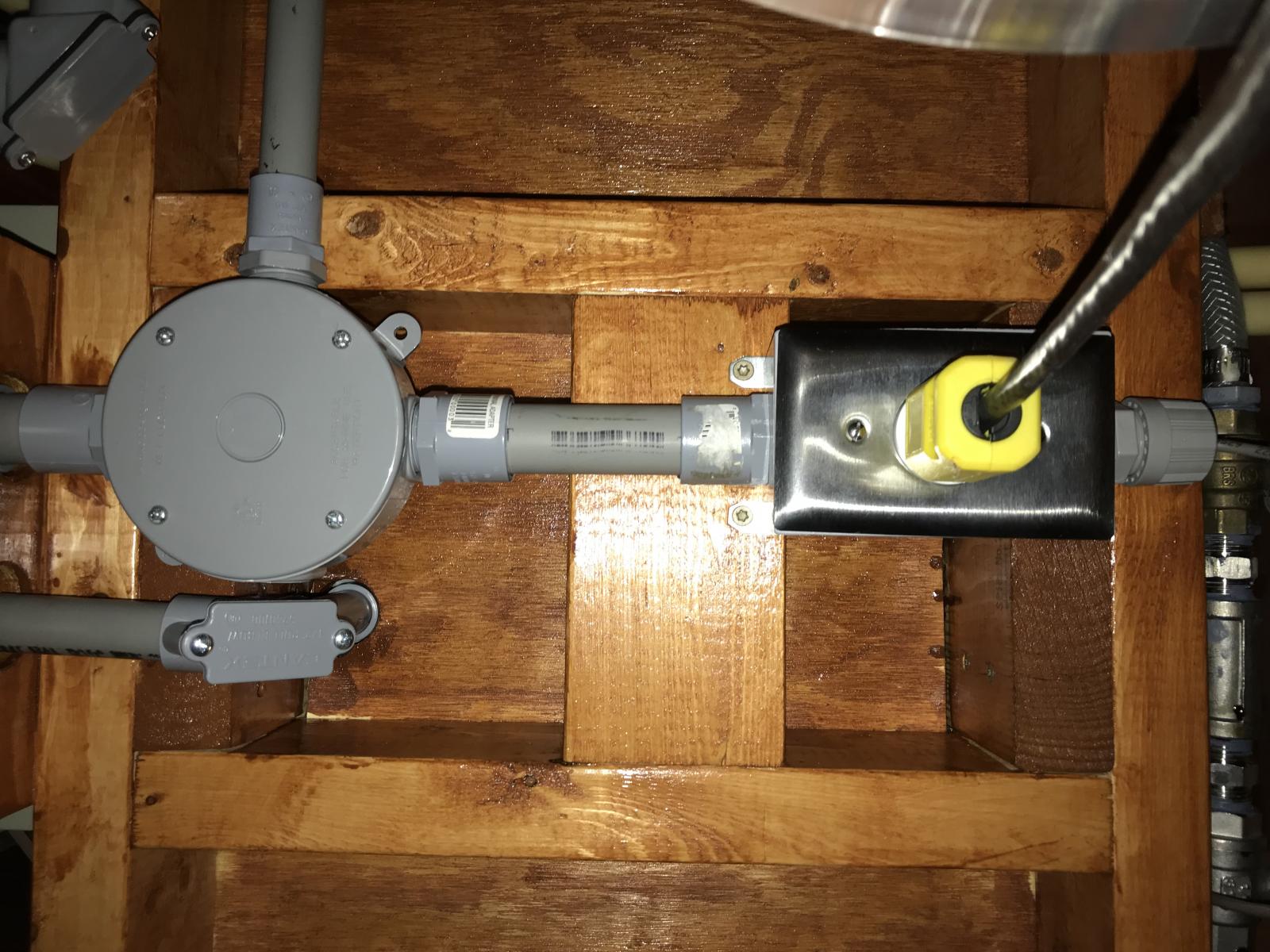

One barrier to entry for a lot of people seems to be getting GFCI to your brew sytem. You might have 240v already wired in your house in your laundry or kitchen, but it doesn't have GFCI. No matter what we do we gotta hire an electrician to come out and spend lots of money. Why not integrate a GFCI panel into the brew stand and supply power to it with an extension cord? This way the brew stand it self is GFCI protected and *relatively* portable.

Take a look at these drawings and let me know what you think of the concept. Do you see any safety issues? Any issues at all?

Everything in this stand can be purchased at your local big box store except for the SSVR, heatsink, and a few cord grips. The switches and such are contained in standard weatherproof outlet boxes like these

http://www.homedepot.com/p/BELL-1-G...1-2-in-or-3-4-in-Outlets-PSB37550WH/202284521

http://www.homedepot.com/p/1-Gang-H...xtra-Duty-While-in-Use-Cover-MM420C/100173013

and this for main power cutoff:

http://www.homedepot.com/p/Leviton-...ntal-Vertical-Orientation-Gray-1432/301940702

Normally when we talk about going electric 240v this involves hundreds of dollars to into the thousands in sexy lit up control panels with ever expanding automation and electronics and gadgets and the list goes on...

In the spirit of BIAB, what about a system with the power of 240v but with the simplicity of stove top brewing?

All you really need to do is to safely provide 240 v to a heating element in a pot, and have a knob (just like a stove) to turn the heat up and down. An SSVR with a rheostat. This can be done really super cheaply.

One barrier to entry for a lot of people seems to be getting GFCI to your brew sytem. You might have 240v already wired in your house in your laundry or kitchen, but it doesn't have GFCI. No matter what we do we gotta hire an electrician to come out and spend lots of money. Why not integrate a GFCI panel into the brew stand and supply power to it with an extension cord? This way the brew stand it self is GFCI protected and *relatively* portable.

Take a look at these drawings and let me know what you think of the concept. Do you see any safety issues? Any issues at all?

Everything in this stand can be purchased at your local big box store except for the SSVR, heatsink, and a few cord grips. The switches and such are contained in standard weatherproof outlet boxes like these

http://www.homedepot.com/p/BELL-1-G...1-2-in-or-3-4-in-Outlets-PSB37550WH/202284521

http://www.homedepot.com/p/1-Gang-H...xtra-Duty-While-in-Use-Cover-MM420C/100173013

and this for main power cutoff:

http://www.homedepot.com/p/Leviton-...ntal-Vertical-Orientation-Gray-1432/301940702