A couple quick notes after a bunch more trials:

When using sucrose, you really should invert it first. I was a disbeliever in that for a long time, but sucrose isn't a reducing sugar, while fructose/glucose are. So while the sucrose will invert from heat and acidity as the syrup darkens, you'll get better results more quickly if the sugar is pre-inverted. The important thing is to neutralize the acidity required to invert before you caramelize the rest of the syrup. Different bicarbonates, like potassium bicarbonate, are used for that.

I came across an article from the 1920's that talks about commercial invert sugar production. The author of that article recommended using citric or tartaric acid over inorganic acids like phosphoric because the flavor isn't as good. Here's his recipe:

On a 1000-pound producing basis, 750 pounds of sucrose,

250 pounds of water (approximately 30 gallons), and 10 ounces

of tartaric or 13 ounces of citric acid are used. The sucrose is

dissolved in the water by stirring while the heat is being raised

to the boiling point. The acid, dissolved in a small quantity

of water, is added to the sugar and water before the heat is applied

and the whole mixture is heated until it boils gently and is held

at incipient boiling for 30 minutes.

The DAP is a good ingredient to use because phosphates increase the rate of Maillard reactions. Ammonia and phosphate compounds are routinely used in commercial caramel production.

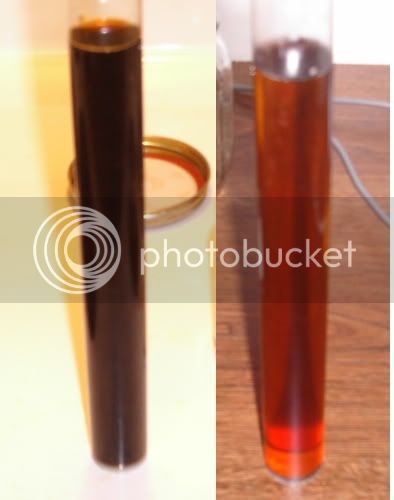

The darker the syrup gets, the less useful the thermometer is, and the more you have to go by feel and experience. The Maillard products burn more easily, but more Maillard products are formed at lower water activity levels. Meaning, the drier the product, the more Maillard products, for better and worse. Some Maillard products are good, some are bad. Balancing them is the hardest part of making the really dark syrups.

The weather can also mess up your syrup, low pressure especially. If the weather is bad or there's weather moving in, it's not a great day to make syrup.

Doh!!!

Doh!!!