Hello,

I've lurked for a while and gotten some good info of the forums.

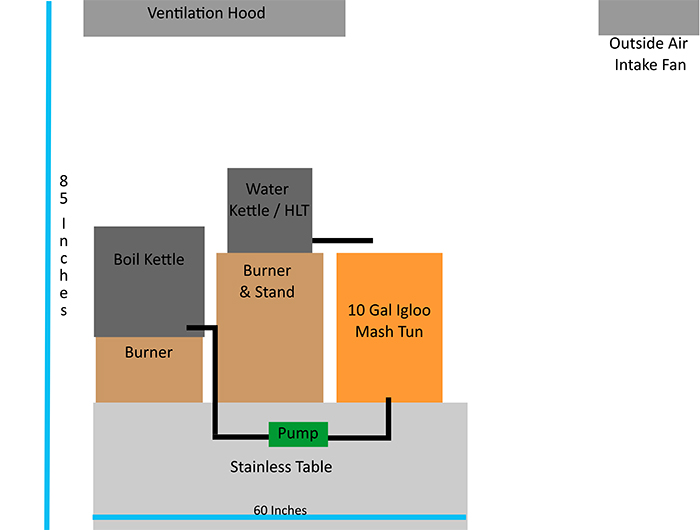

I've been extract brewing for a while and am building my 1st All Grain setup and am looking for some feedback.

I've done a good amount of reading and watched some all grain brewing video's and this is what I came up with to fit my situation.

I'm in Wisconsin so brewing outdoor year around is not possible, the table will be brought inside during the winter. All gas lines will be attached to the table and just require attaching to the quick disconnect in my basement and my deck.

- Running off natural gas

- Outdoor from spring to fall

- Indoor during winter (Basement has exhaust hood and separate outdoor air intake fan)

- Water boil/HLT and Boiling kettle pot are next to each other so both are under the exhaust hood when indoors

- 5 and 10 gallon batches

Any feedback anyone has about what will and wont work with my setup is greatly appreciated.

I've lurked for a while and gotten some good info of the forums.

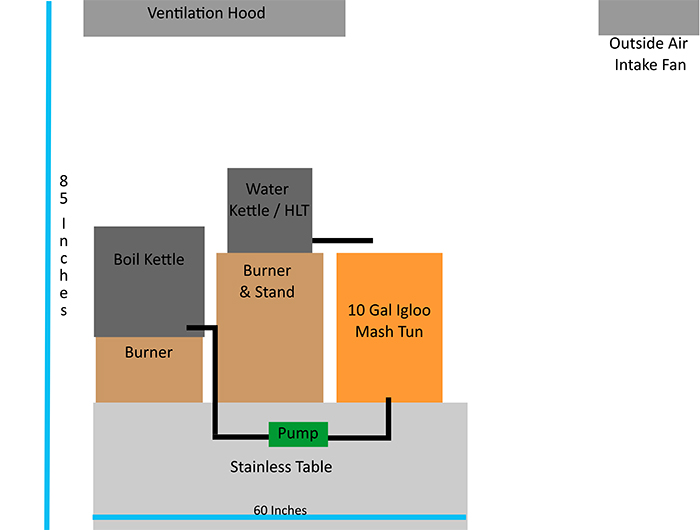

I've been extract brewing for a while and am building my 1st All Grain setup and am looking for some feedback.

I've done a good amount of reading and watched some all grain brewing video's and this is what I came up with to fit my situation.

I'm in Wisconsin so brewing outdoor year around is not possible, the table will be brought inside during the winter. All gas lines will be attached to the table and just require attaching to the quick disconnect in my basement and my deck.

- Running off natural gas

- Outdoor from spring to fall

- Indoor during winter (Basement has exhaust hood and separate outdoor air intake fan)

- Water boil/HLT and Boiling kettle pot are next to each other so both are under the exhaust hood when indoors

- 5 and 10 gallon batches

Any feedback anyone has about what will and wont work with my setup is greatly appreciated.