aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

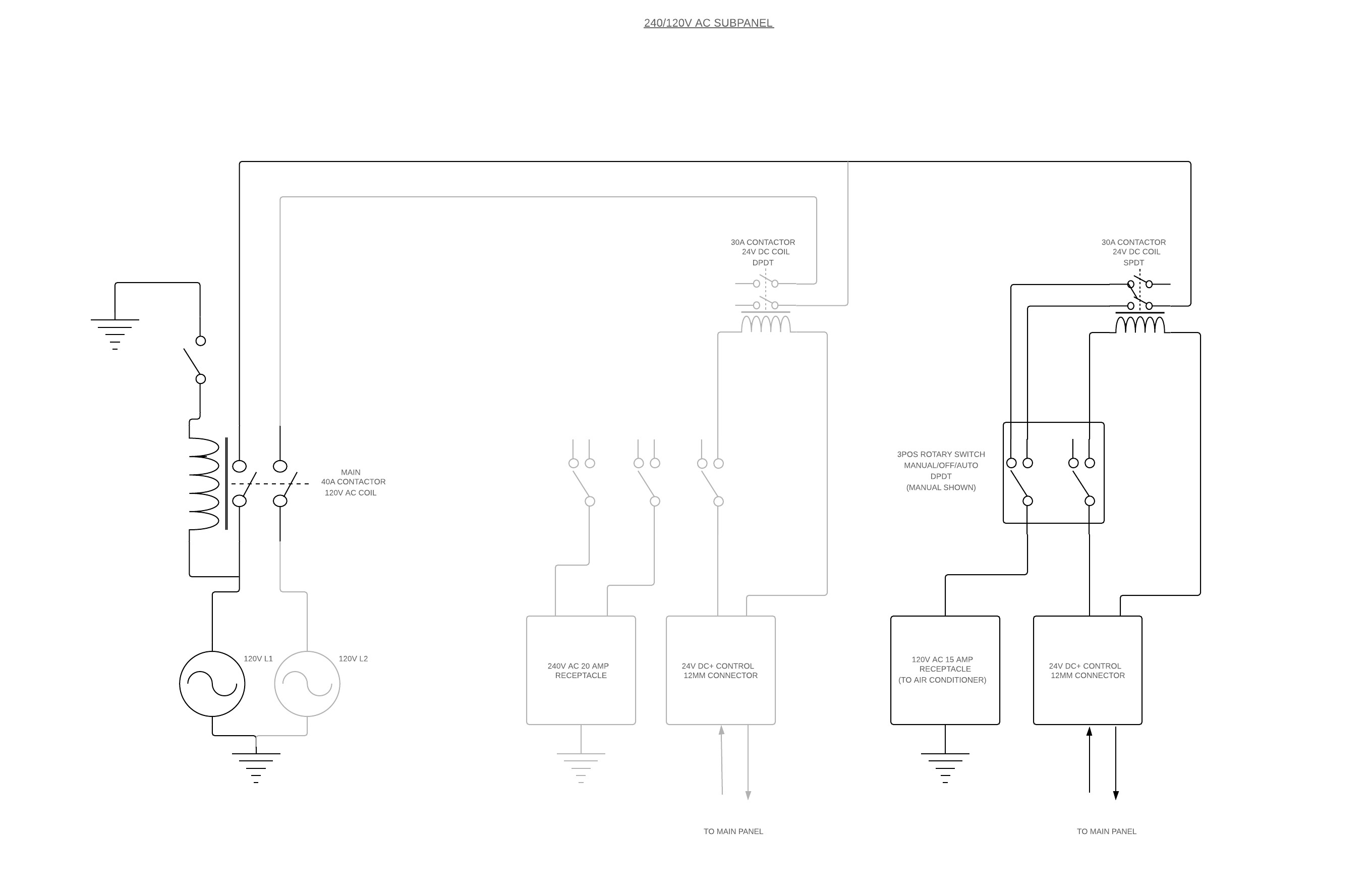

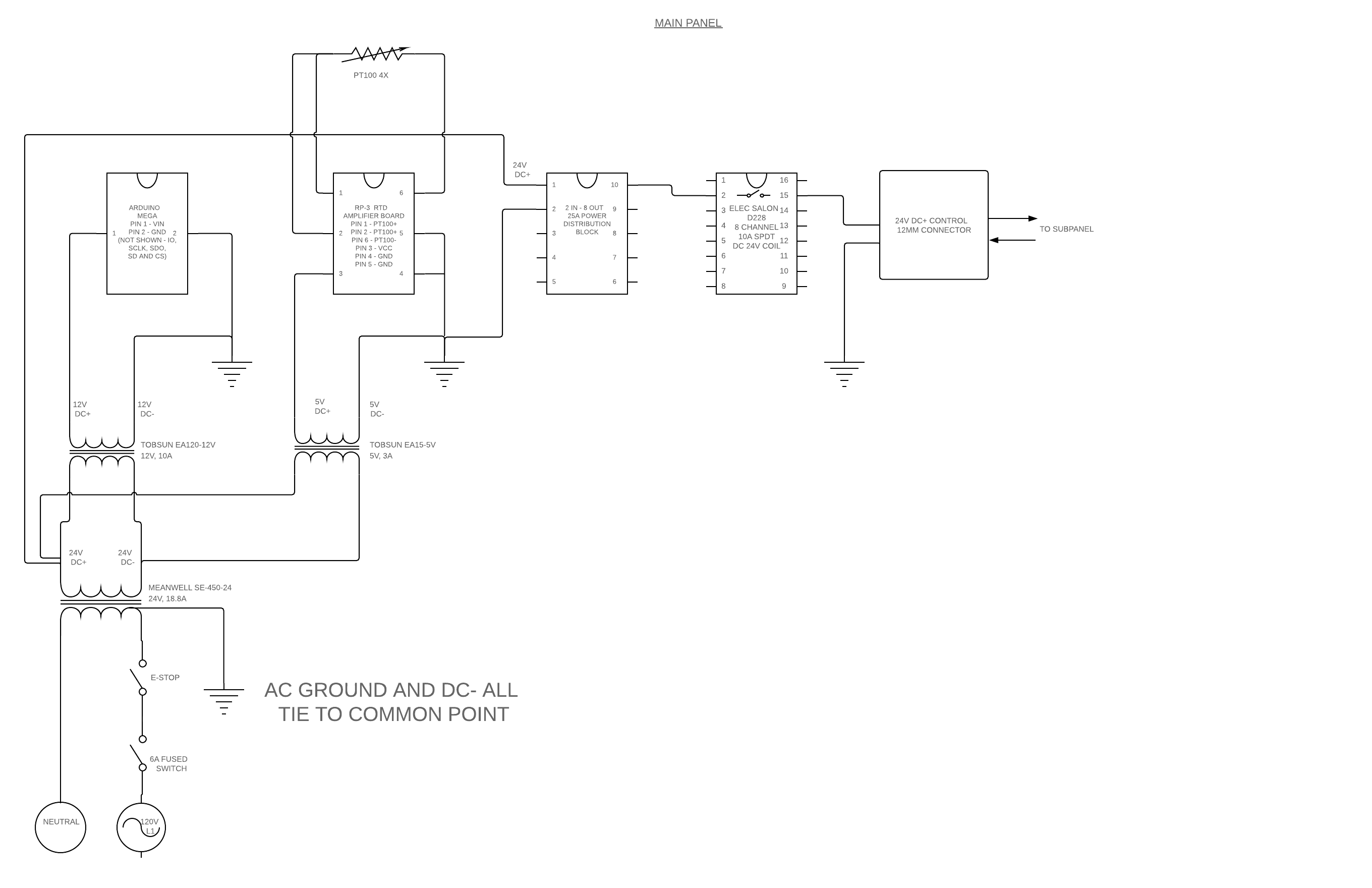

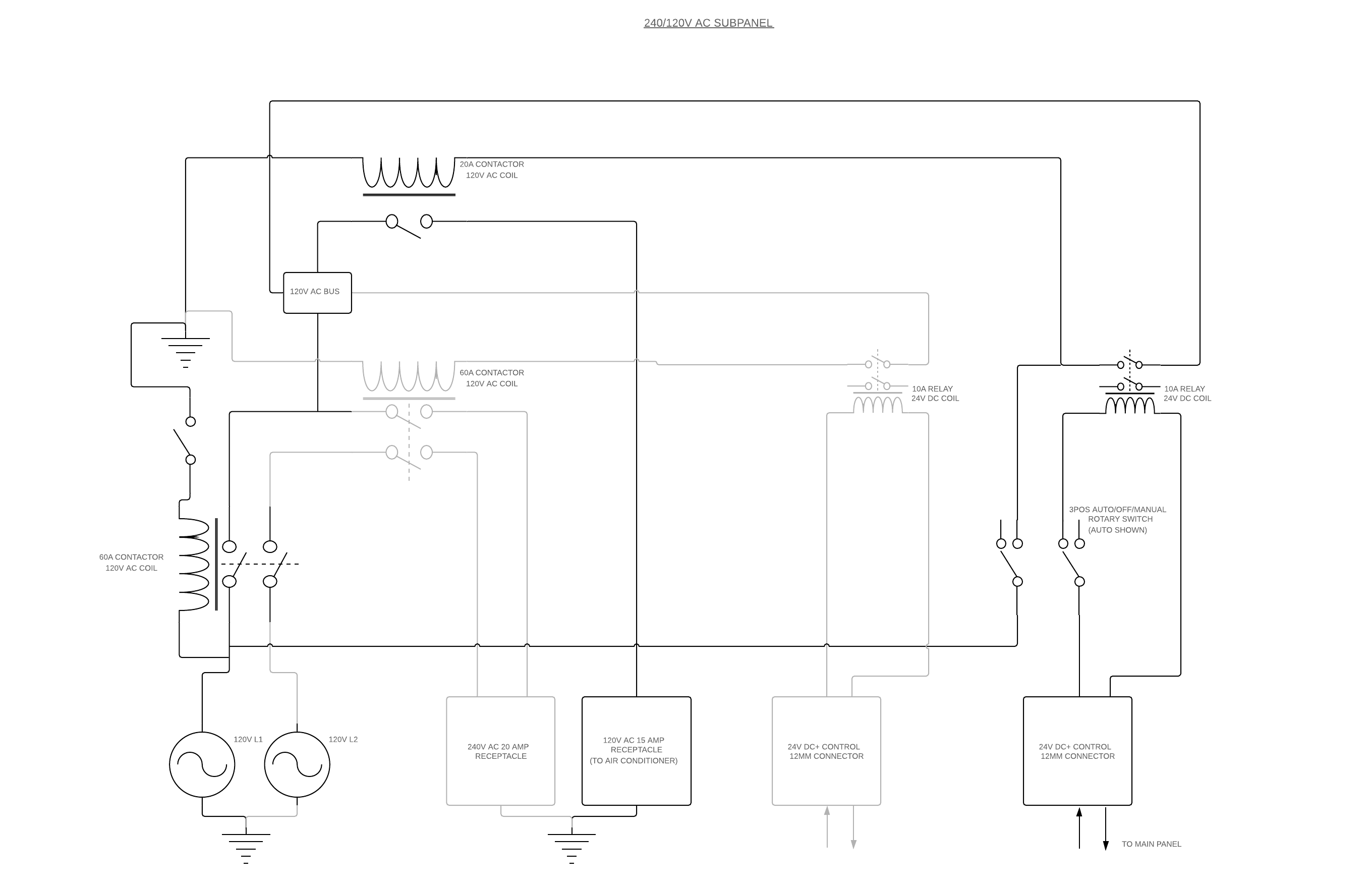

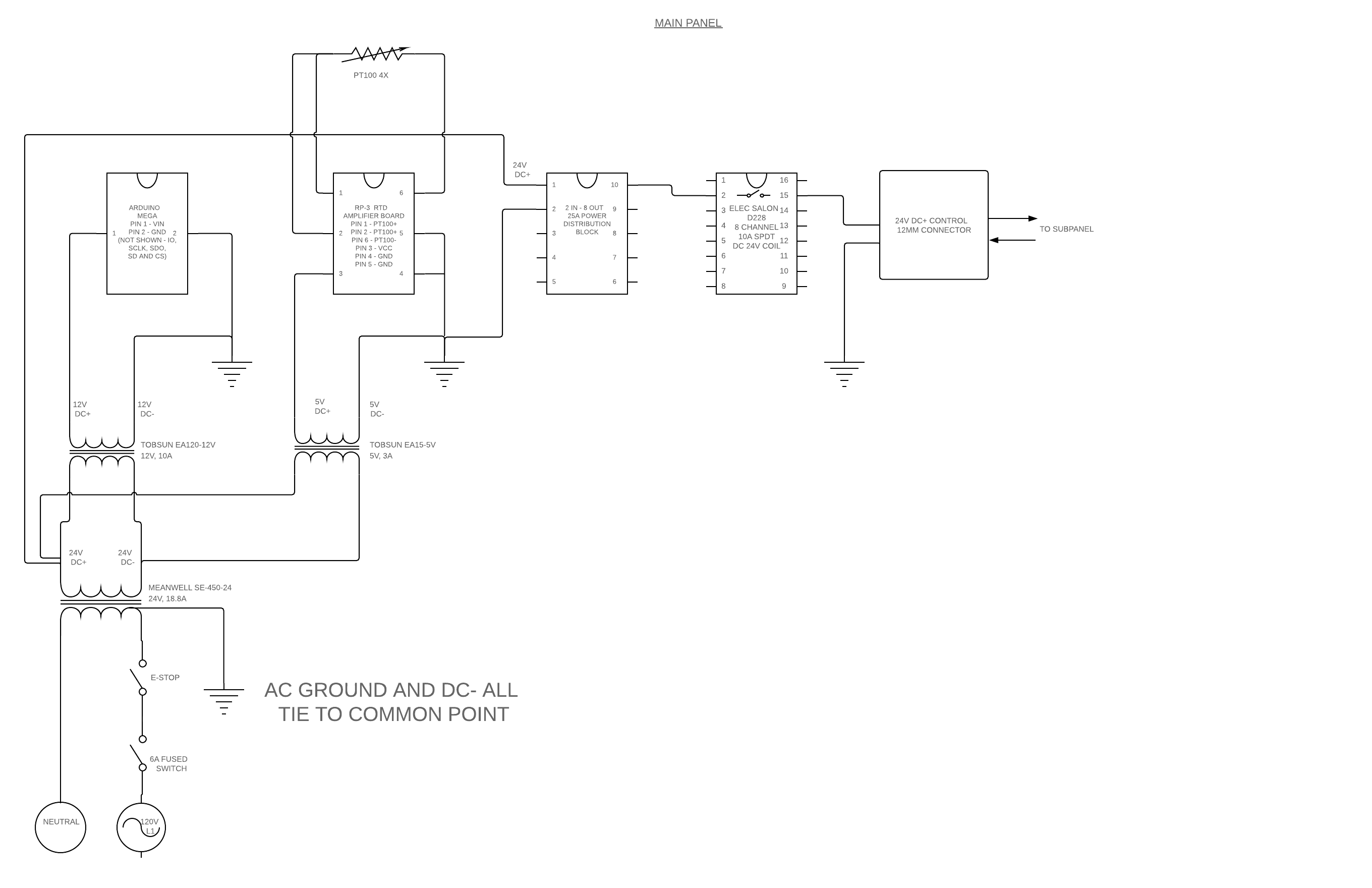

You are correct, the picture shows a breaker, ac contactor, DC relay, physical switch, and a receptacle, lets call this the subpanel. The idea behind this is I plug this subpanel into my main panel. The 24v DC output from the main panel controls the DC relay which controls the contactor. This lets power to the fridge (which is an air conditioner). I believe the answer to your power supply question is Yes, the 5v amplifier board and 24vdc output are on the same circuit. To clarify, see attached wiring diagrams, the first shows the main panel the second shows the sub panel. Regarding the sub panel, only the dark gray lines are currently wired. When finished, this will control a 240v AC, not 120v (as shown).Im not really sure what we are looking at here. I think you have a breaker, ac contactor, DC relay, physical switch, and a plug. What are these doing? Where is the DC power coming from and how is it wired to your board? Is the plug for an AC unit or a fridge? And is the power supply for the RTD from the same power circuit? If your 5v power supply is on the same circuit then it will be affected by the inductive load. You could also try a capacitor across the + and - on the 5v to smooth it out.

I hoped to provide more information on the wiring diagram but my trial limited out the QTY of features, the website wouldnt allow my payment

I see the dip from SPI sensor when A/C cycles. This is also observed when the AC is manually controlled (via sub panel) and NOT connected to output of the main panel. For this test, both sub panel and main panel are on completely different circuits. Also, everything is working fine when I use a lightbulb or a heatlamp at output. Something to do with the A/C

Looking forward to hear any criticism to the below diagrams.

Last edited: