I rarely use an old variable as I generally like to see my variables. I thought the inspector was sort of clunky as it required the loop. If you switch your variables to Global Elements, you can use them in any section in any script. It may be how and when you are declaring the variables that they are "section" only. I do not think that would be a "normal" attribute, and I have not run into that issue. However, I use the old variables for some internal script math (such as to figure an offset from a strike Global) only, so I am not calling them often.

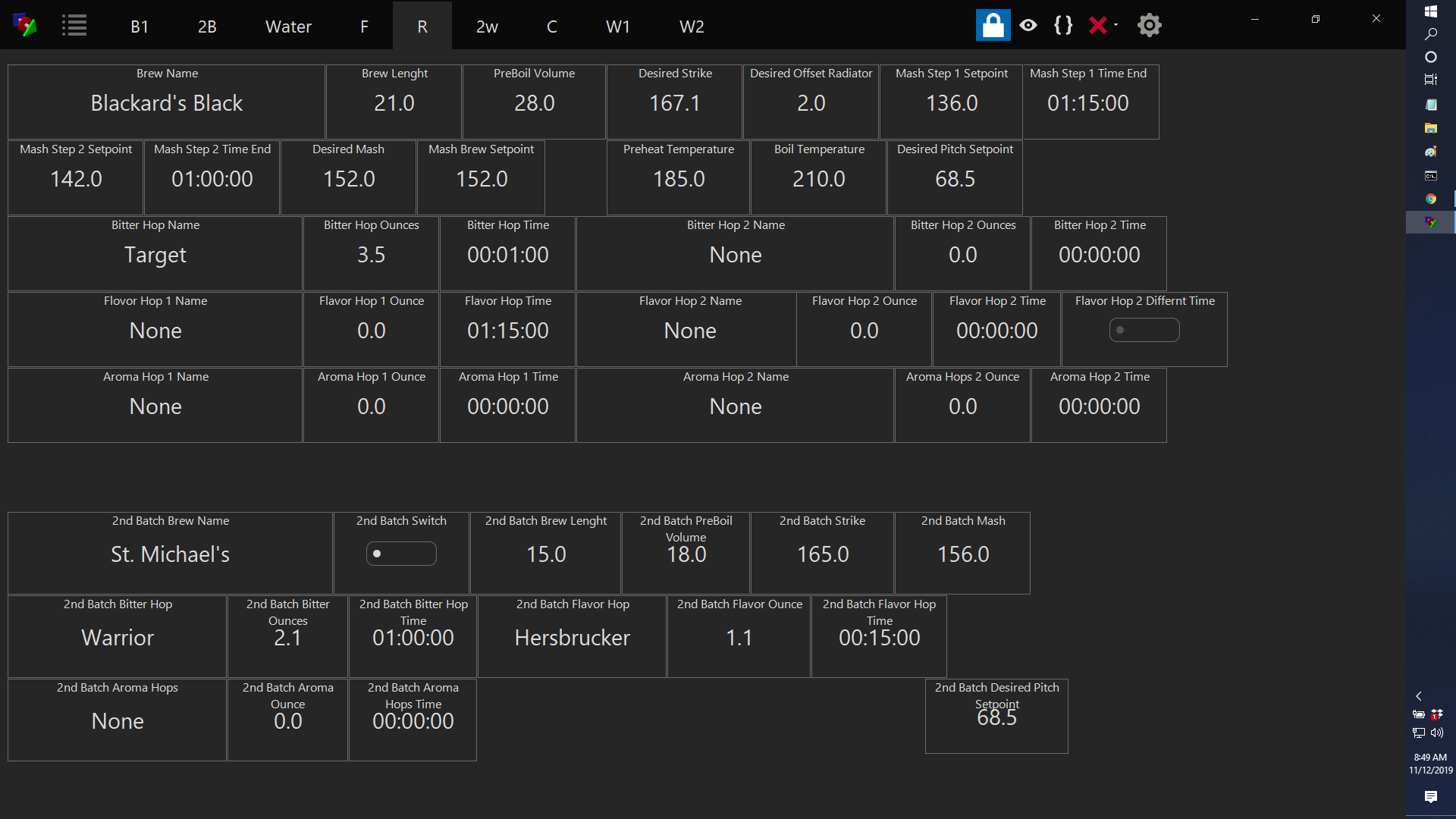

Here is an example of a lot of Globals that I use in scripts for a particular brew. I am hoping to transfer most of these from a stored file as I know that you can do that, I just do not know how yet. I know there are threads about Beer Smith imports. Some are just names and amounts that I use in screen messages, but some are used to trigger an alarm or advance a script. We tend to do the same brews on a repetitive basis.

View attachment 652249

By having these as Globals, I can quickly change or review things I need to know for a brew, rather than going into and editing a script for a Mash Temp, for example.

I plan to create a separate Fermentation Configuration or Workspace in the near future with different Global Variables such as Fermentation Temps and Glycol Temp Values.