2drunk2

Well-Known Member

I love nottingham. I was drinking my IPA at 3 weeks when using it.

... then proceeded to bottle the sanitised bottles - again with the mini auto-siphon. There was a bit of a learning curve, but it wasn't long before we were moving quite efficiently.

Well, a few days after bottling, the question on my mind is: How can I tell if the beer is carbonating?

I've been keeping the bottles in a dark area where the ambient temperature is 68 to 72 degrees, which as far as I can tell from reading seems like an optimum temperature range.

I took a peek this morning, and it dawned on me that I really don't know any obvious signs that the beer is carbonating, other than perhaps shaking it up and potentially watching the cap blow off. There was some sediment on the bottom of the few random bottles I checked, and it seemed at first that this would be the most telling sign of carbonation - but what if that sediment is simply from the fermenter and got sucked up in the transfer from fermenter to pot, then to the bottle?

I'll wait the proscribed two weeks (perhaps three) before opening any bottles and finding out for sure, but in the meantime, I was wondering if there are any reliable, observable signs that I could be advised of.

Thanks in advance -

Ron

Oh, but it is important to look at them every day so they don't think you've forgotten about them. It motivates them to try harder. Same as when it's fermenting, you have to "check on it" every day. Or is that just me?

Alright, the 2-week "waiting period" following bottling has come and gone; due to being rather ill (flat-out SICK would be a better word) the past few days, I've decided to go ahead and give my first brew one more week in the bottle to condition before sampling.

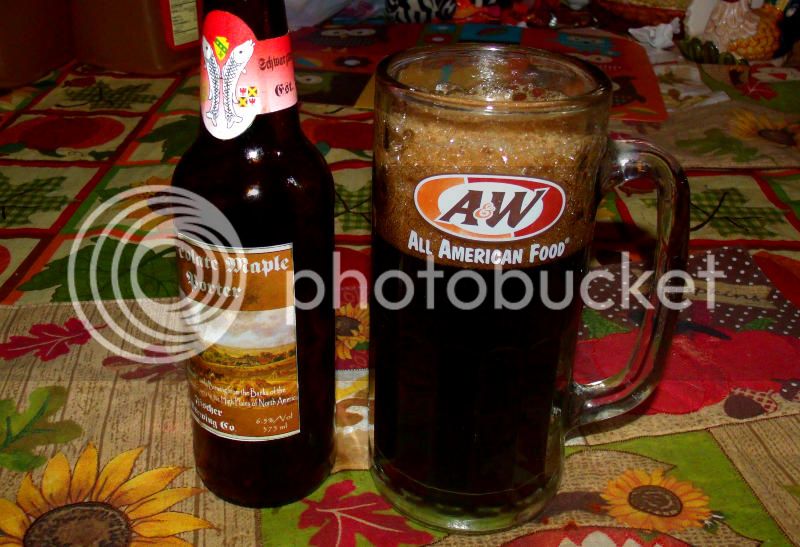

I took a peek at the bottles this morning, and was pleased to see that no caps have blown and everything looks good (I assume). There is the same very-small amount of fine-looking sediment that I noticed before, about the same amount that I see in bottle-conditioned beer that I buy at the store. While looking them over, I accidentally dropped one bottle, but caught it before it hit the table. I noticed the same bubbling up at the neck that I would expect from a fully-carbonated beer, so it looks to me as though I've been successful in making beer.

Will it be good? That remains to be seen. I'll put a bottle in the refrigerator on Friday night, and then sample it on Sunday. I realise that I am placing the whole process on a pedastal that is higher than it probably deserves to be, but what the hell, it's my first!

In the meantime, @JINKS over in the labeling forum took some concepts and images that were rolling around in my mind and transformed them into a very nice label for my bottles:

He also came up with a design for neck labels as well:

I'm thinking that things are looking pretty good for this project!

Due to several factors, including work and my above-mentioned illness, I haven't yet been able to brew my second batch of beer (Oatmeal Cookie Stout), but plan on doing so this weekend.

@PitRow - Mike, I forgot about it at the time, but I do in fact have one of those bottle wands/fillers, exactly as you described! It came with the initial kit that my wife got for me for my birthday, and I had it packed away with all of my 5-gallon brewing equipment. I'll give it a try on my next project!

You bottle 10 gallons a week? Do you drink it that fast?

Another option that I just thought of -

I have a 6.5-quart enamled cast-iron Dutch oven. Since it's just a one-gallon batch, this might work well for the mash, as it will hold the temperature very well. I can switch to my thinner 8-quart stainless-steel stock pot for boiling.

I might try this next time and see how it goes....

Enter your email address to join: