Bottoms_Up

Well-Known Member

I think I now have a fix for the Brewzilla Gen 4 temperature calibration issue!

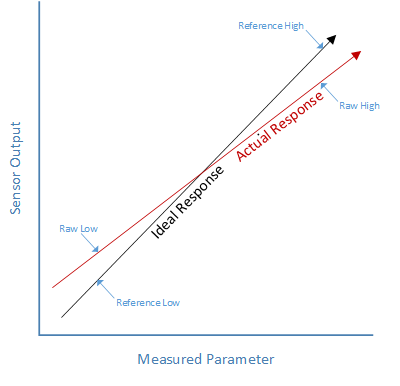

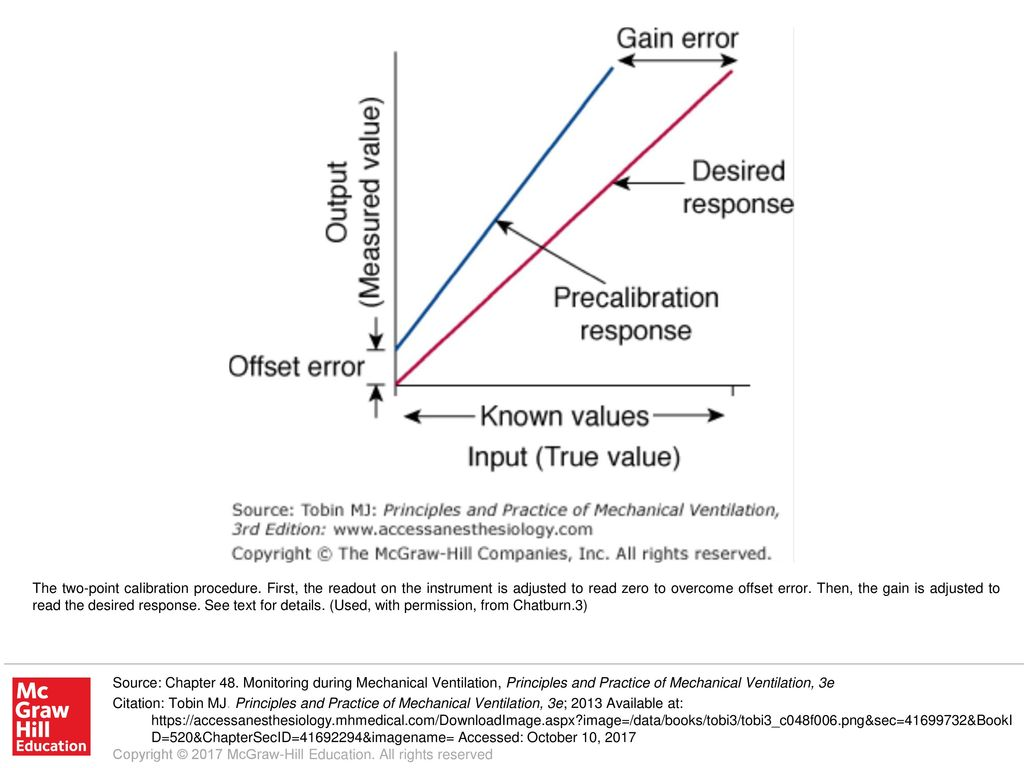

After my third attempt at trying to resolve the temperature difference on my Brewzilla, I think I sort of understand how the calibration algorithm works, at least in general. Knowing how it works is the first step of the solution. I was not able to find out from Kegland what the actual algorithm was, so I had to figure it out by logical deduction. I think the algorithm adjusts the entire temperature range rather than fix two points. Let me explain by using a simple example. I'll use the metric system as the example since there is exactly 100 degrees between the freezing point and the boiling point at sea level, so it is easier to illustrate. (For the Imperial system, it is obviously 180 degrees).

Let's say you measure your Brewzilla temperature with room temperature water, and find it reads low. This could be because the freezing point reads, let's say, 5 degrees too low and the boiling point reads 5 degrees too high. Thus there is a 110 degree range between the freezing point (0) and the boiling point (100). There should only be 100 degrees between these two points.

So you add ice water to the Brewzilla, run the recirculation arm and let the temperature adjust. The Brewzilla reads -5.0 C rather than 0. So you set the calibration point by raising it 5 degrees. Now there is a 105 degree spread between the freezing point and the boiling point rather than 110. Now when you read the water at room temperature, you are closer, but still it is out.

What has happened is that by raising it 5 degrees, you are still 5 degrees out in total. Brewzilla spreads this difference by splitting the 5 in half. So now when you go to the boiling point calibration, the Brewzilla reads 2.5 degrees too high. So you set the calibration point 2.5 degrees lower. Now you have a total range of 102.5. So the range still has 2.5 degrees too much. So it divides the difference, and now, if you were to go back to the freezing temperature, it would read 1.25 degrees too low. You adjust again. Each time the total difference will be halved as to what it was before. So you can repeat the calibration again and again until you feel it is close enough. It will never reach a range of exactly 100, because you are dividing the difference by a half each time.

So the bottom line is that if your Brewzilla is only a degree or two out initially, you may only need to do the calibration once. It should be close enough. But, if you are out by, for example, 7 degrees, as I was, you will need to repeat the calibration at least 3 times, or whenever you can live with the difference.

Note that my explanation is a simplification based on observation and deduction. There may be additional factors in the calibration algorithm, but I think that it is basically how it works.

I think there might be a trick to do it just once. If you were to initially take the reading at the freezing point as well as at the boiling point, and determine the entire spread (e.g. let's say 110 degrees), then if you were to just add that entire difference (10 degrees) at the freezing point calibration (rather than the correct temperature at that point), you should end up with the right range immediately, and thus all the temperatures should line up. Or even easier, rather than going back to the freezing point again, just make the adjustments while you're at the boiling point - and lower it by the difference. That way you only have to do it once.

I haven't tried this, but if anyone does, please let us know how it turned out.

After my third attempt at trying to resolve the temperature difference on my Brewzilla, I think I sort of understand how the calibration algorithm works, at least in general. Knowing how it works is the first step of the solution. I was not able to find out from Kegland what the actual algorithm was, so I had to figure it out by logical deduction. I think the algorithm adjusts the entire temperature range rather than fix two points. Let me explain by using a simple example. I'll use the metric system as the example since there is exactly 100 degrees between the freezing point and the boiling point at sea level, so it is easier to illustrate. (For the Imperial system, it is obviously 180 degrees).

Let's say you measure your Brewzilla temperature with room temperature water, and find it reads low. This could be because the freezing point reads, let's say, 5 degrees too low and the boiling point reads 5 degrees too high. Thus there is a 110 degree range between the freezing point (0) and the boiling point (100). There should only be 100 degrees between these two points.

So you add ice water to the Brewzilla, run the recirculation arm and let the temperature adjust. The Brewzilla reads -5.0 C rather than 0. So you set the calibration point by raising it 5 degrees. Now there is a 105 degree spread between the freezing point and the boiling point rather than 110. Now when you read the water at room temperature, you are closer, but still it is out.

What has happened is that by raising it 5 degrees, you are still 5 degrees out in total. Brewzilla spreads this difference by splitting the 5 in half. So now when you go to the boiling point calibration, the Brewzilla reads 2.5 degrees too high. So you set the calibration point 2.5 degrees lower. Now you have a total range of 102.5. So the range still has 2.5 degrees too much. So it divides the difference, and now, if you were to go back to the freezing temperature, it would read 1.25 degrees too low. You adjust again. Each time the total difference will be halved as to what it was before. So you can repeat the calibration again and again until you feel it is close enough. It will never reach a range of exactly 100, because you are dividing the difference by a half each time.

So the bottom line is that if your Brewzilla is only a degree or two out initially, you may only need to do the calibration once. It should be close enough. But, if you are out by, for example, 7 degrees, as I was, you will need to repeat the calibration at least 3 times, or whenever you can live with the difference.

Note that my explanation is a simplification based on observation and deduction. There may be additional factors in the calibration algorithm, but I think that it is basically how it works.

I think there might be a trick to do it just once. If you were to initially take the reading at the freezing point as well as at the boiling point, and determine the entire spread (e.g. let's say 110 degrees), then if you were to just add that entire difference (10 degrees) at the freezing point calibration (rather than the correct temperature at that point), you should end up with the right range immediately, and thus all the temperatures should line up. Or even easier, rather than going back to the freezing point again, just make the adjustments while you're at the boiling point - and lower it by the difference. That way you only have to do it once.

I haven't tried this, but if anyone does, please let us know how it turned out.

Last edited: