That's an interesting idea. I must say that I lower empty basket in and stir with a giant grout mixer attached to a Makita drill full blast (high torque gear). Never an issue with the pump per se. Besides a stuck mash, but pump was fine. As soon as the basket drain, pump would do its thing.

I've also been using a spiral drill mixer for at dough-in.

But after a couple of badly stuck mashes, I've been looking at everyone's ideas.

Not much taken by the idea to lower pipe with some grain in, to stop the base lifting. I'm sure just a little grain, would mostly float, and lots would make it hard to then stir.

A few places explicitly say don't put grain into a raised malt pipe, as flour will get part 'sieved' through. This will then, either be carried up during recirculation to form a flour 'crust' on top of the grain, that blocks the flow, or settle out on false bottom and base, where it may burn during the boil.

Anyway I don't seem to have any issue with grains escaping the malt pipe, (from the bottom lifting). If there was, I'd just push base down with paddle after lowering.

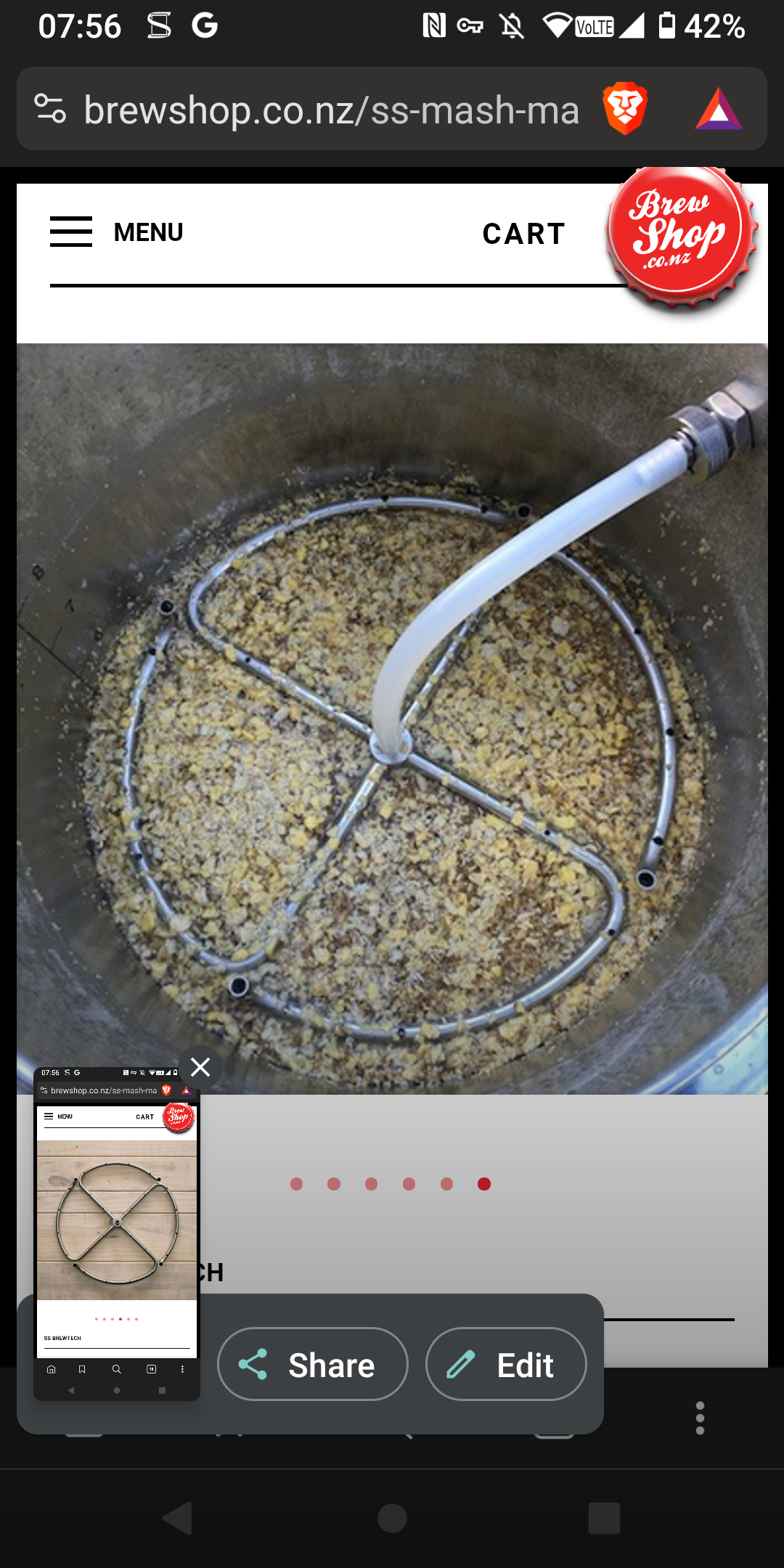

My problem always seems to be in the malt pipe.

I've had 50% wheat recipe stick, when recirculating from start. I think doing that, flushed the flour out.

Same recipe, but 50min grain bed rest, before medium recirculation, worked fine.

So I'm thinking resting the bed helped. Rest allowed the grains and flour to hydrate with the flour staying well distributed.

Would a 20min rest be long enough?

Recently spotted that Graham Wheeler says (British real ale 3rd ed.) Stir thoroughly to avoid dry pockets, but

don't over-stir or the grain will become waterlogged. Air trapped in the grain is what makes it float. If all this air is knocked out it, looses buoyancy, and will pack down more on the base.

Total extra effective weight of the grain, from none having any buoyancy, can result in a compacted bed and set mash.

That sounds very plausible. And makes me wonder if (drill) over-stirring sometimes, has been my whole problem.

So my next brew will be with a slow drill speed! - for just long enough to separate any clumps. And have a 30minute grain bed rest.

And have my fingers crossed.