Jackanapes

Member

- Joined

- Nov 17, 2018

- Messages

- 9

- Reaction score

- 2

I've been planning to make the jump to electric brewing for a while now and was about to take the final plunge until I got thrown for a big loop recently. I was informed by an electrician that running a new 30A/240V GFCI line would be prohibitively expensive for me to justify (mainly due to upgrading service to the house, but a lot of other work would have been required as well).

I wanted to run some ideas past people with experience in electric brewing and get any input. I do have two circuits running to my garage, a 20A/120V GFCI and the other 15A/120V regular. I was thinking I could go with dual elements in the boil kettle, 2200W (kettle mounted) and 1600W (either mounted in the kettle or heatstick).

Any other input would be greatly appreciated. Thank you.

I wanted to run some ideas past people with experience in electric brewing and get any input. I do have two circuits running to my garage, a 20A/120V GFCI and the other 15A/120V regular. I was thinking I could go with dual elements in the boil kettle, 2200W (kettle mounted) and 1600W (either mounted in the kettle or heatstick).

- Would this be sufficient for a rolling boil for a 5-6 gallon batch?

- Any recommendations for a 10 gallon kettle configuration for dual elements?

- Would a control panel for at least one of the elements be needed and/or recommended?

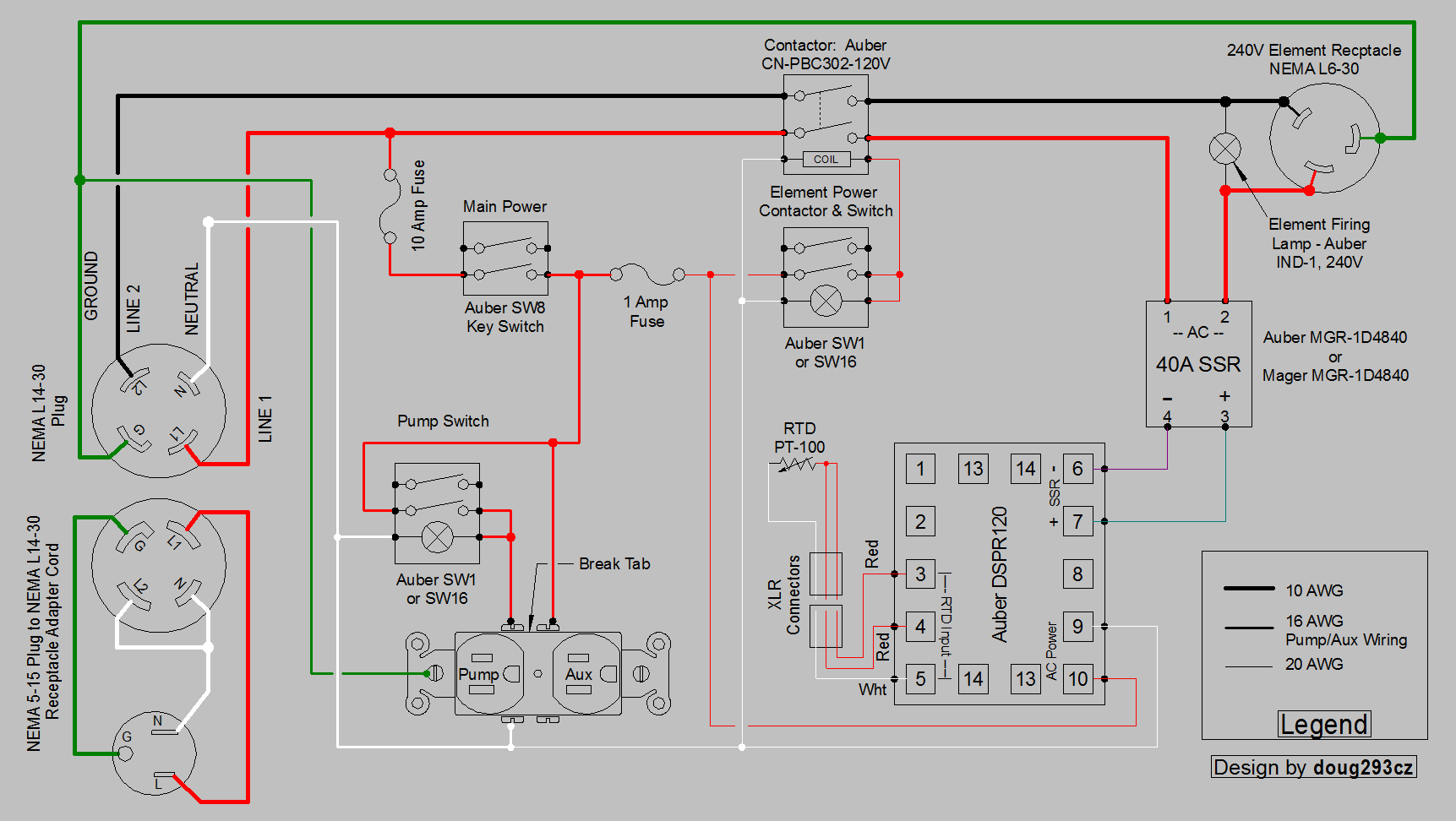

- If a control panel is recommended, could I just take a 30A/240V design and feed it 20A/120V without problem, or would certain components (besides 120v vs 240v LEDs) need to be swapped? I would like to futureproof in case I move or get access to a 30A line.

- Maybe a newb question, didn't think to ask the electrician: I do have relatively close access to a 40A/240V non-GFCI outlet for my electric range. Besides getting it on a GFCI breaker, would it be possible use that and would the standard 30A/240V items (panel/elements) work fine with it?

Any other input would be greatly appreciated. Thank you.

Last edited: