nosnhojm20

Well-Known Member

I think I have SWMBO sold on a brew shed build. I'll be taking out a massive loan to buy/build this and fence in the yard so that the kids and dogs can play outside without much supervision, freeing me up to brew way more often.

Now I'm soliciting feedback because this is NOT something I can afford to do twice (estimated at $5k based on below). Any feedback is completely welcome, I'm sure some people here have already done something similar and any "if I could do it again" are particularly welcome.

The Plan:

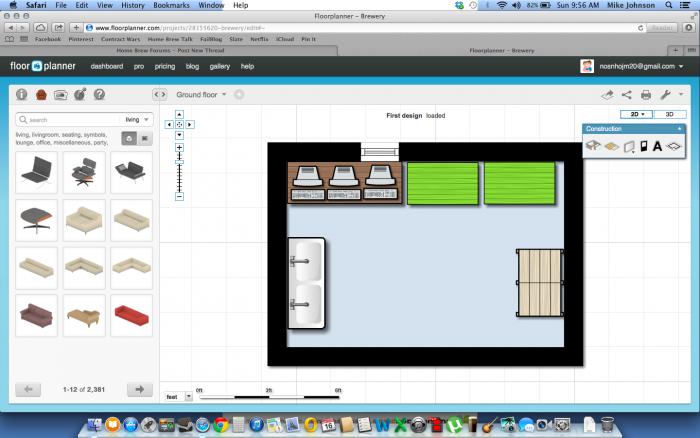

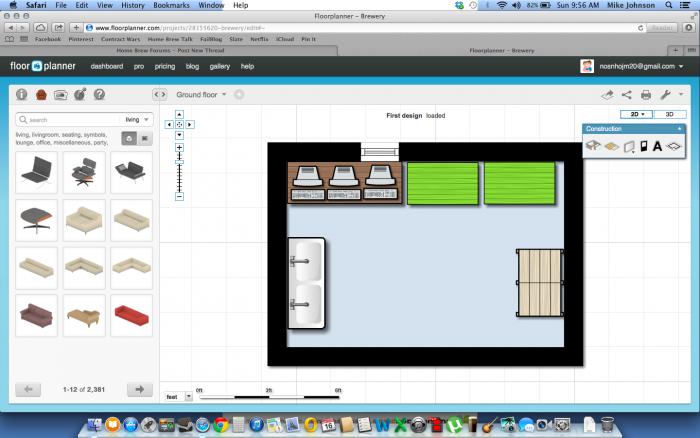

The Picture (attached):

The Questions I have off the top of my head:

Thanks in advance, all. It is much appreciated.

Now I'm soliciting feedback because this is NOT something I can afford to do twice (estimated at $5k based on below). Any feedback is completely welcome, I'm sure some people here have already done something similar and any "if I could do it again" are particularly welcome.

The Plan:

- I'm planning electric and automated. I will be using High Gravity Brewing's cheaper electric control panel (EBC II). This will keep costs relatively low and fit my needs (automating a HERMS mash/HLT). I will be adding a second pump as this will be a single tier build. Actually, all/most electrical equipment will be coming from them, too.

- The shed will have an extra window in the back for a box fan for ventilation pulling the steam out, cracking other windows for cross-vent. I'll be going with a 10x12 shed.

- I want to use 3 19 gallon vessels from AIH to be flexible with 5/10 gallon batches.

- Two pumps to run the rig allowing me to whirlpool the HLT while recirculating, and of course for transferring the wort.

- Professional electrician will be contracted to run the electricity to the shed.

- The sink would only provide water on brewday, and for light rinsing. I am not sure the code in my area but I am not too interested in running drain lines and hooking up to the septic system (other side of house).

The Picture (attached):

- The computers are supposed to be the vessels. The free software doesn't have brew kettles, go figure.

- The green boxes are the kegerator and fermentation chamber.

- I'd like to have a sink that is hooked up to the garden hose. I need to figure out the regs on drainage for my area but am not overly concerned right now. The brown thing on the right is shelving.

The Questions I have off the top of my head:

- Do I have to insulate for the winter/summer? I figure the chest freezers will do alright in the summer, and then fans and heating pads for the winter to regulate the cold.

- This is a shed, it is not insulated. Do I need to put up some kind of sheetrock or other wall material due to the moisture created by the boil? I figure long term this would be a good idea as the shed isn't cheap but I am not sure where to start on this one.

- With the temperature swings for summer/winter are my ideas adequate?

- Any feedback about the vendors I plan on using? This is my first go at electric, I've never actually seen one in action so... yea, any feedback would be helpful.

- Do I need a hood for the ventilation or is the cheapo box fan enough? In a year or two I'd like to install a hood but right now in an effort to keep costs low (cue to laugh as I'm planning on dropping 5-6k already) I'd prefer to hold off.

Thanks in advance, all. It is much appreciated.