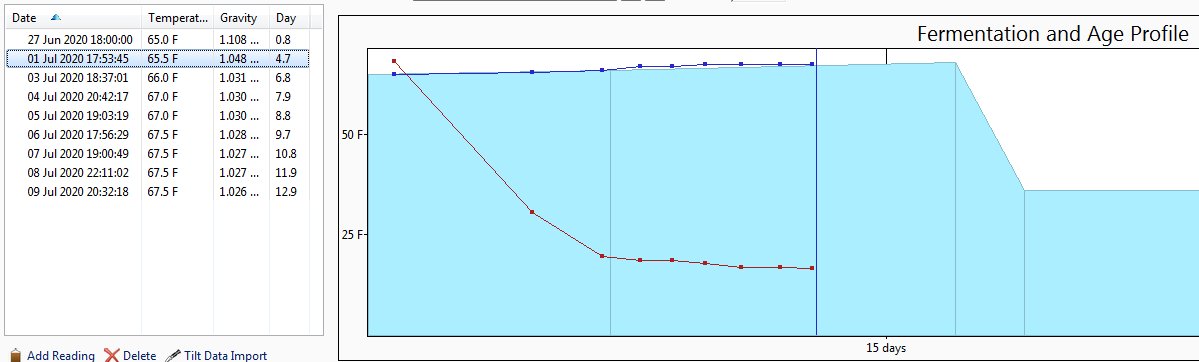

To "celebrate" being stuck at home I gave myself the project to brew high gravity beers each week to fill my kegs. Along the way I made some system adjustments on my 20g eBIAB system mainly where I discovered if I double crushed I could finally hit an OG in the 1.10 range. Normally I never come close but this is the first time I've done big beers back to back. Since I only have 2 fermenters I only give each batch 2 weeks before moving it. I've started to notice that nearly all of them are still in the 1.038 range after a few weeks and one, a Russian Imperial Stout, seems stuck there. So my questions are:

- Is it normal for high gravity beers to take longer? I've rarely seen an ale need more than 2 weeks to finish. But I've never got my OG this high before.

- If I find one of them is stuck in the 1.038 range, is there anything I can do to fix it? I was going to try Champagne yeast but I searched here and found quite a few posts saying to not do that.