I plan to use white sugar to prime bottles. I need to know how many cups per gallon to just prime a dry cider. I am going to backsweeten and pasteurize my bottles once carbed. Does anyone know how much sugar to backsweeten on top of the priming sugar. I saw 1/4 cup but not sure if.that was per gal. Or per 5gal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

backsweetening and carbing

- Thread starter Krausen89

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Earlier this week someone pointed me to Northern Brewer's Priming Sugar Calculator. According to that calculator, you would need 23.22 grams of sucrose (white sugar) to prime 1 gallon at 70F (the temperature matters) to 2.5 volumes (the pressure matters).

As far as back sweetening goes, I guess that's a matter of taste. One YouTube video suggested adding sweetener little by little to a sample of your unprimed cider, then, when you get to the desired sweetness, measure the SG. Then add sweetener to your unprimed cider until it achieves that same SG. Then add your priming sweetener and bottle. Then, when the desired CO2 volume is achieved, pasteurize stop fermentation.

As far as back sweetening goes, I guess that's a matter of taste. One YouTube video suggested adding sweetener little by little to a sample of your unprimed cider, then, when you get to the desired sweetness, measure the SG. Then add sweetener to your unprimed cider until it achieves that same SG. Then add your priming sweetener and bottle. Then, when the desired CO2 volume is achieved, pasteurize stop fermentation.

What are you going to use to back sweeten. If sugar, you will not need to prime the bottles.. That sweetener will ferment and carb at the same time. The trick is to "guess" when the bottles reach the proper carb stage for you to pasteurize. That has been discussed to death in the sticky.

However, if you are going to let the cider ferment till dry, and are going to back sweeten with a non fermentable sugar like xylitol, then you can add 1 rounded tsp/12 oz bottle and cap.. no need to ferment. It takes about 7 tsp of sugar to make one ounce. If you were going to prime a bottle of ale, you would use about 1 oz per gallon.

It's not clear to me what your plan is.

However, if you are going to let the cider ferment till dry, and are going to back sweeten with a non fermentable sugar like xylitol, then you can add 1 rounded tsp/12 oz bottle and cap.. no need to ferment. It takes about 7 tsp of sugar to make one ounce. If you were going to prime a bottle of ale, you would use about 1 oz per gallon.

It's not clear to me what your plan is.

What are you going to use to back sweeten. If sugar, you will not need to prime the bottles.. That sweetener will ferment and carb at the same time. The trick is to "guess" when the bottles reach the proper carb stage for you to pasteurize. That has been discussed to death in the sticky.

However, if you are going to let the cider ferment till dry, and are going to back sweeten with a non fermentable sugar like xylitol, then you can add 1 rounded tsp/12 oz bottle and cap.. no need to ferment. It takes about 7 tsp of sugar to make one ounce. If you were going to prime a bottle of ale, you would use about 1 oz per gallon.

It's not clear to me what your plan is.

I will be back sweetening the same time i am priming. The idea is that you create the volumes of co2 that you want and leave sugars behind.(with one addition of sugar) I will be killing the yeast by pasteurizing while the cider is in the bottles. The cider is still fermenting now that i look at it and its been about a month. No sugars added. Wild yeast and fermenting at 50-55 degrees F. Might change the plan. Could take the gravity and just bottle and pasteurize

BeastYeast

Member

- Joined

- Jan 17, 2014

- Messages

- 23

- Reaction score

- 2

First Post! :rockin:

What's up brewers! I've been lingering and borrowing recipes from this form for a while, but I am still a beginner, especially to cider. I currently have a couple 5 gallon primaries going, one of which will be a nice caramel apple cider I found on this forum. The other I'm unsure of how I want to use the finished primary. These are my first runs of carboys, previously I used EZ caps to tinker with making grape, apple and pineapple ciders.

While the 5 gallons were doing their thing I also put together (3) growlers (64 fl ounces) consisting of the same ingredients as the carboys (I experimented with different yeasts), which have finished fermenting and I want to tinker with some flavoring and sweetening. I normally keg and force carb everything so I'm rather inexperienced at botting.

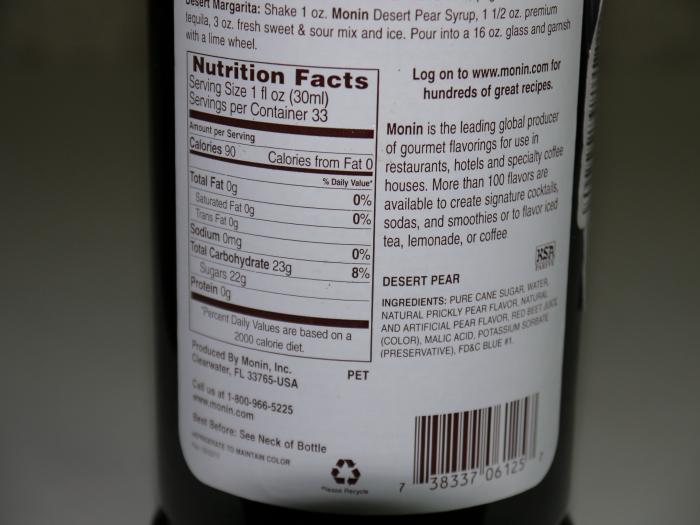

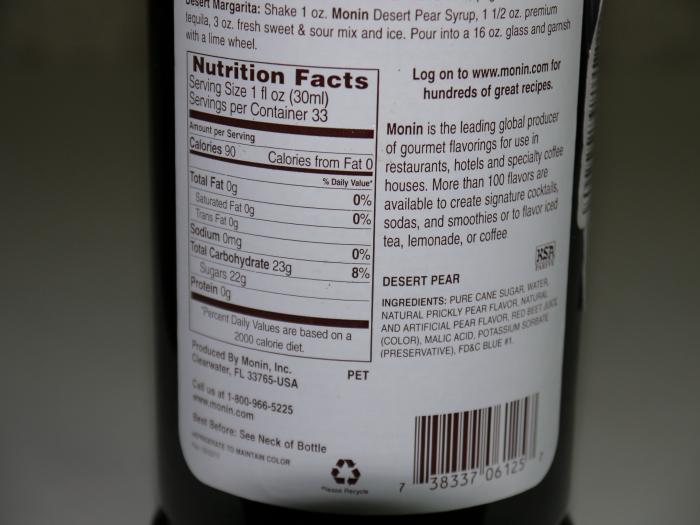

The growlers pretty much fermented right out and finished right about 1.00, so along with flavor a little sweetness would be just fine. So, I'd like to flavor with some pear flavored syrup I picked up and I'm not sure how to tackle it.

I'd like to:

1. Add pear flavor

2. Carbonate

3. Sweetening is fine but not essential. If I do a large batch I will backsweeten in secondary and keg to force carb. This could probably be accomplished with the pear syrup alone. That said I would like a reasonably similar sample result from the growler.

Should I:

1. Use the syrup for flavor and carb and either forget sweetenin/use artificial sweeteners.

2. Use the syrup for flavor and sweetener, then stovetop pasteurize.

I'm looking for some input from you gurus, any advice or suggestions are welcome. Thank you in advance

EDIT: I just noticed after posting that the syrup has preservatives in it. I'm not exactly sure how this will effect my options. Will the syrup fail to ferment resulting in the syrup adding flavor and sweetness? If so, will this prevent any other added sugars from fermenting for carbing?

What's up brewers! I've been lingering and borrowing recipes from this form for a while, but I am still a beginner, especially to cider. I currently have a couple 5 gallon primaries going, one of which will be a nice caramel apple cider I found on this forum. The other I'm unsure of how I want to use the finished primary. These are my first runs of carboys, previously I used EZ caps to tinker with making grape, apple and pineapple ciders.

While the 5 gallons were doing their thing I also put together (3) growlers (64 fl ounces) consisting of the same ingredients as the carboys (I experimented with different yeasts), which have finished fermenting and I want to tinker with some flavoring and sweetening. I normally keg and force carb everything so I'm rather inexperienced at botting.

The growlers pretty much fermented right out and finished right about 1.00, so along with flavor a little sweetness would be just fine. So, I'd like to flavor with some pear flavored syrup I picked up and I'm not sure how to tackle it.

I'd like to:

1. Add pear flavor

2. Carbonate

3. Sweetening is fine but not essential. If I do a large batch I will backsweeten in secondary and keg to force carb. This could probably be accomplished with the pear syrup alone. That said I would like a reasonably similar sample result from the growler.

Should I:

1. Use the syrup for flavor and carb and either forget sweetenin/use artificial sweeteners.

2. Use the syrup for flavor and sweetener, then stovetop pasteurize.

I'm looking for some input from you gurus, any advice or suggestions are welcome. Thank you in advance

EDIT: I just noticed after posting that the syrup has preservatives in it. I'm not exactly sure how this will effect my options. Will the syrup fail to ferment resulting in the syrup adding flavor and sweetness? If so, will this prevent any other added sugars from fermenting for carbing?

Boins

Member

I use the layman back sweeten/carb method. I just back-sweeten to flavor and cap. as I do this, I also fill a 1 liter plastic soda bottle. after a few days, I give the soda bottle a squeeze. As long as the pressure matches (or is less) than what a normal soda bottle would feel like, then its time to pasteurize which completes the process. I'm a new cider brewer but so far I have a few hundred bottles done this way and not one bomb.

I know there are calculations for specific carb without over doing it, but for me the simpler the better.

I know there are calculations for specific carb without over doing it, but for me the simpler the better.

BeastYeast

Member

- Joined

- Jan 17, 2014

- Messages

- 23

- Reaction score

- 2

Thanks for the reply!

I ammended my previous post with this addition:

I just noticed after posting that the syrup has preservatives in it. I'm not exactly sure how this will effect my options. Will the syrup fail to ferment resulting in the syrup adding flavor and sweetness? If so, will this prevent any other added sugars from fermenting for carbing?

I definitely like the idea of that method, and if I were botting a whole carboy that would definitely be my route. Since these are only 64 oz growlers I didn't really want to remove any volume from them as they are currently. Although I do realize I may have no other choice.

Go figure, I got rid of ALL of my PET bottles when I got a keg system thinking they were useless lol. I suppose I could just do one growler spread out through 3 20 oz pop bottles or a two liter for a sample to test sweetness and carb.

I ammended my previous post with this addition:

I just noticed after posting that the syrup has preservatives in it. I'm not exactly sure how this will effect my options. Will the syrup fail to ferment resulting in the syrup adding flavor and sweetness? If so, will this prevent any other added sugars from fermenting for carbing?

I definitely like the idea of that method, and if I were botting a whole carboy that would definitely be my route. Since these are only 64 oz growlers I didn't really want to remove any volume from them as they are currently. Although I do realize I may have no other choice.

Go figure, I got rid of ALL of my PET bottles when I got a keg system thinking they were useless lol. I suppose I could just do one growler spread out through 3 20 oz pop bottles or a two liter for a sample to test sweetness and carb.

Similar threads

Latest posts

-

-

-

British Golden Ale Miraculix Best - Classic English Ale

- Latest: Erik the Anglophile

-

-

-

-