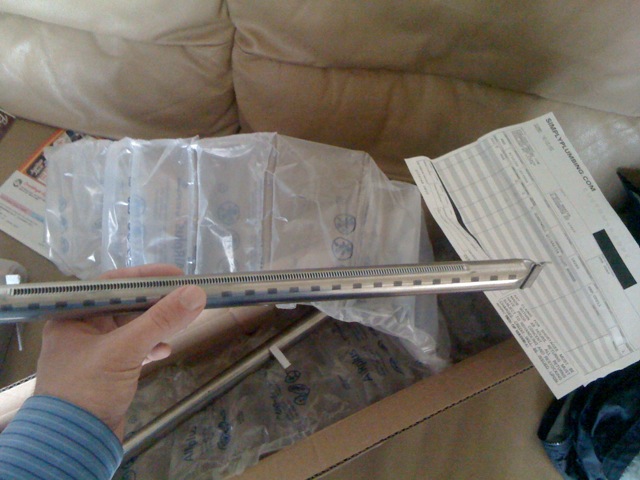

The date of the opening party is getting closer and we keep ordering more parts and more packages keep showing up. Lets take a look at some of the things that have been delivered so far...

On the far left we have the digital temp sensor inside a 4" SS thermowell with a 1" compression fitting to attach it. We have 10" ones for the kettles and this 4" one for the mail recirculating path and cooled wort out. Its pretty cool, fully adjustable length and well made.

Up at the top, next to our prototype tap handle, we have two of the Swagelok 1/2" fittings, one strait, one 90, as recommended earlier in this thread. These things are serious quality and solid.

Under those are the 1.5" tri-clover clamps, so far we only have the 1/2" NPT threaded side, waiting on the barbed side of things to be made for us.

Below that is a solenoid valve from DudaDiesel.com He managed to get us the 10 valves we needed and is now out of stock. These are 2 way valves with a nicer than normal seal on them so they should be able to resist liquid flowing past them, as our design requires.

The big cylinder at the top you will recognize as the march pump, we got in on the group buy and really made out saving $60 on the two pumps we needed.

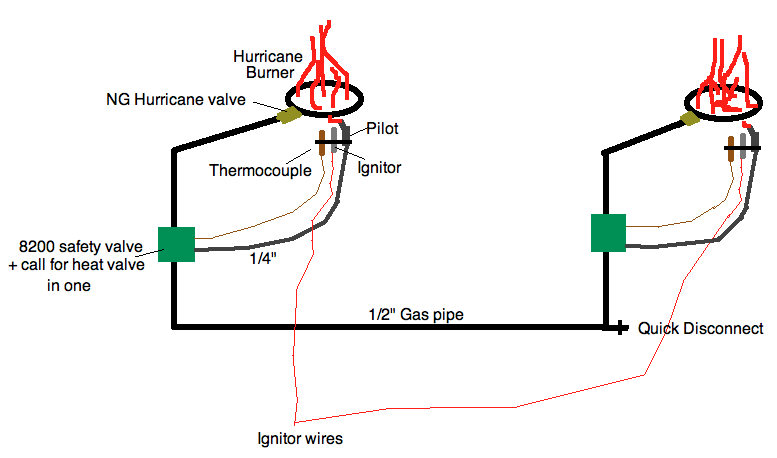

And the weird looking thing at the bottom right is the gas furnace valve we will be using to control the burners.

Our more beer order should be arriving tonight with all the rest of the nuts and bolts we need to assemble everything together. We are hoping to dry fit and test a few things but without the kegs preped there is not a whole lot we can do. We have someone who can cut them up for us. Now it is just a matter of making that happen. Not shown in the picture is the 1/2" SS tubing from McMaster. That came in about 24hours after ordering. Awesome.

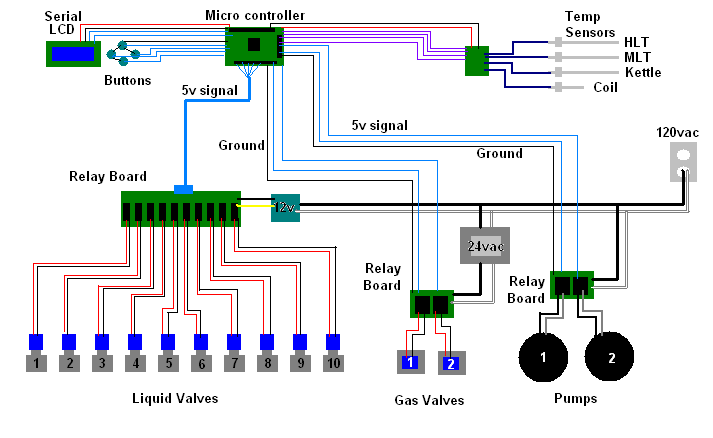

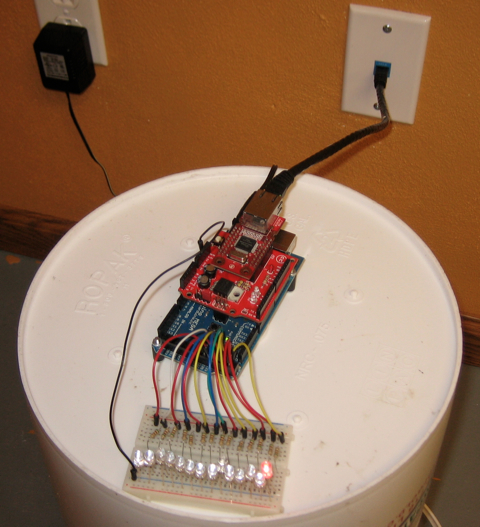

Not having to do construction has giving us some free time to work on the controller that will be doing most of the brewing for us. Here is a picture of the demo setup in the brewery.

Its basically an Arduino MEGA with a NKC ethernet board plugged into it. These are all demo/proto boards which allow us to test things much quicker. A final design would include everything we need in a custom configuration making it permanent but easy to swap out components. In this example the board is connected only to power and ethernet. When powered on it connects to the network, establishes an IP and waits to serve web page requests. By sending a POST or GET command from any web browser on the LAN we can control the arduino. We are testing with LED's which will then be swapped for relays and valves etc. Here is a link to a quick 2min youtube video demoing the network functionality.

[ame="http://www.youtube.com/watch?v=MH_rK-NbEYo"]Demo[/ame]

Hopefully tonight we will get some more work done cleaning up things. We also plan on shooting what will be a presentation/podcast shown at the party in less than two weeks. Its going to be busy but there will be lots of exciting things coming up shortly!

PS - Anyone know how to coil SS tubing? I thought I saw an article on the forums here about using a lathe?