I use an Auber 2352 in my HERMS setup and check its temp probe against a Thermapen in mash temperature water before every brew day. More often than not, the RTD reads a few degrees different than the Thermapen, requiring me to go into the PID settings and change the temperature offset. Does anyone know what would cause this? I'm 99% sure the temp probe is an Auber Pt100 RTD.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Auber 2352 - Different temp offset needed almost every brew day. Why?

- Thread starter kevink

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

LarMoeCur

Well-Known Member

First check your cables. They are the weakest point of RTD temperature probe system. My PIDs were doing the same thing. Checking them with a volt meter, I found that I had two cables with broken solders at the QD. I re-soldered them and a few brews later they started fluctuating again. On the second inspection with the volt meter, this time moving the cable and rechecking, I found that they had gotten twisted and the thin little wires were broken internally. I ordered some new cables and my problem went away.

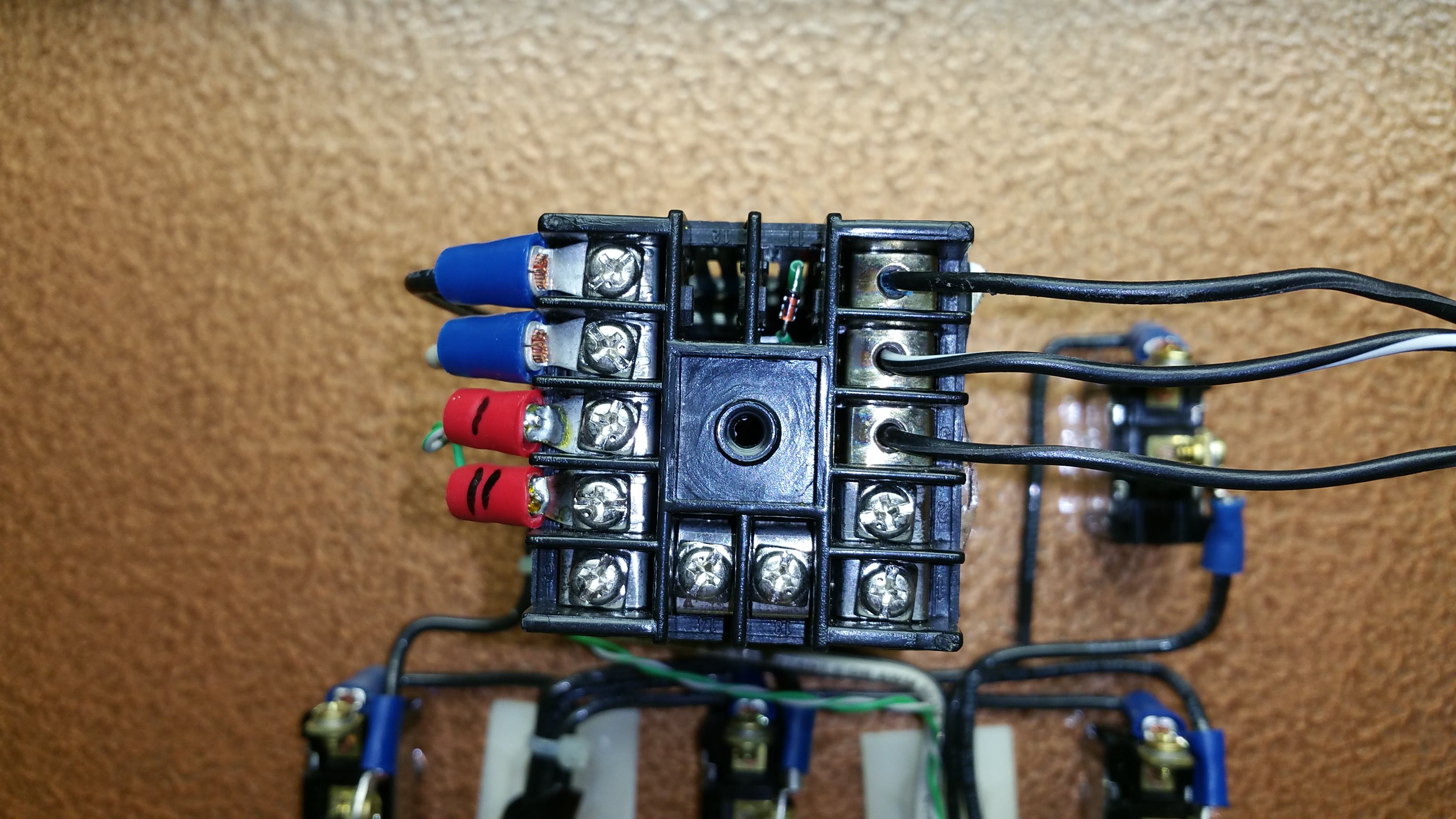

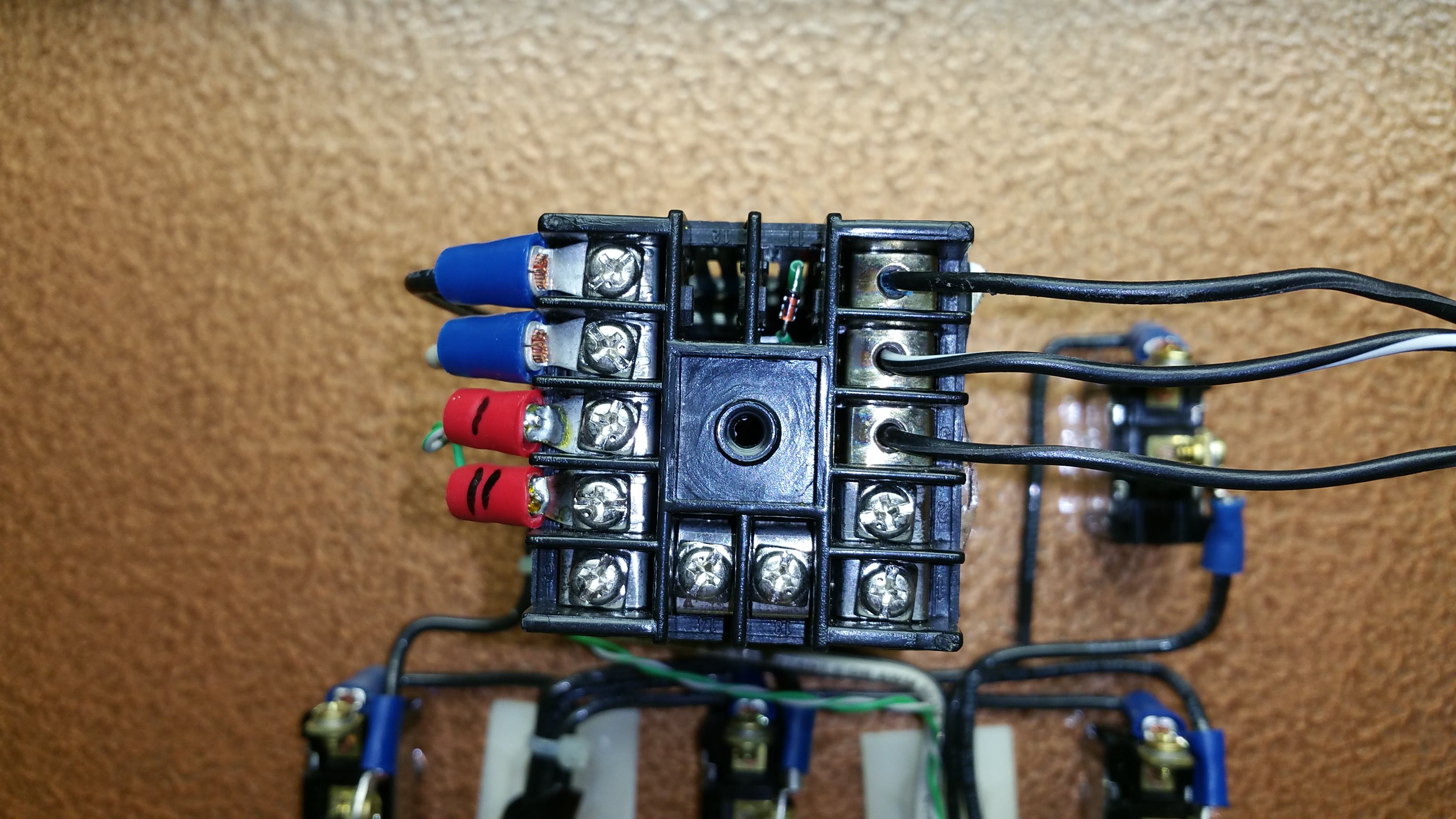

If you're sure your cables are good. Then check the connections on the PIDs. First check the crimp connector on the wires. Unless you have a high dollar crimping tool, they are notorious for coming loose. Second check that all the screws are tight on the PIDs. Opening and closing the enclosure door can work them loose. Lastly check the XLR connector solders. Again opening and closing the encloser can pull on them breaking the solders.

If you're sure your cables are good. Then check the connections on the PIDs. First check the crimp connector on the wires. Unless you have a high dollar crimping tool, they are notorious for coming loose. Second check that all the screws are tight on the PIDs. Opening and closing the enclosure door can work them loose. Lastly check the XLR connector solders. Again opening and closing the encloser can pull on them breaking the solders.

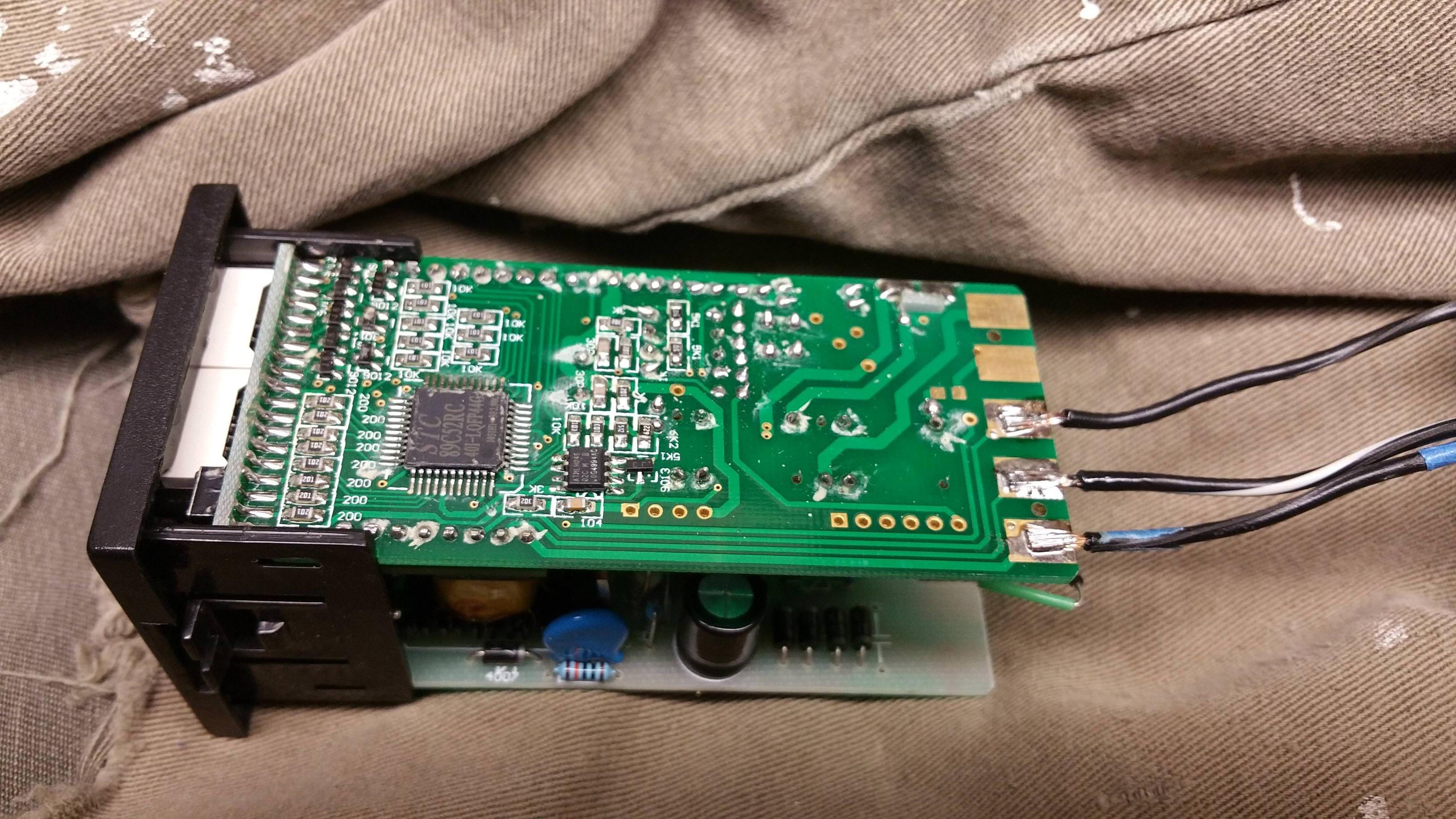

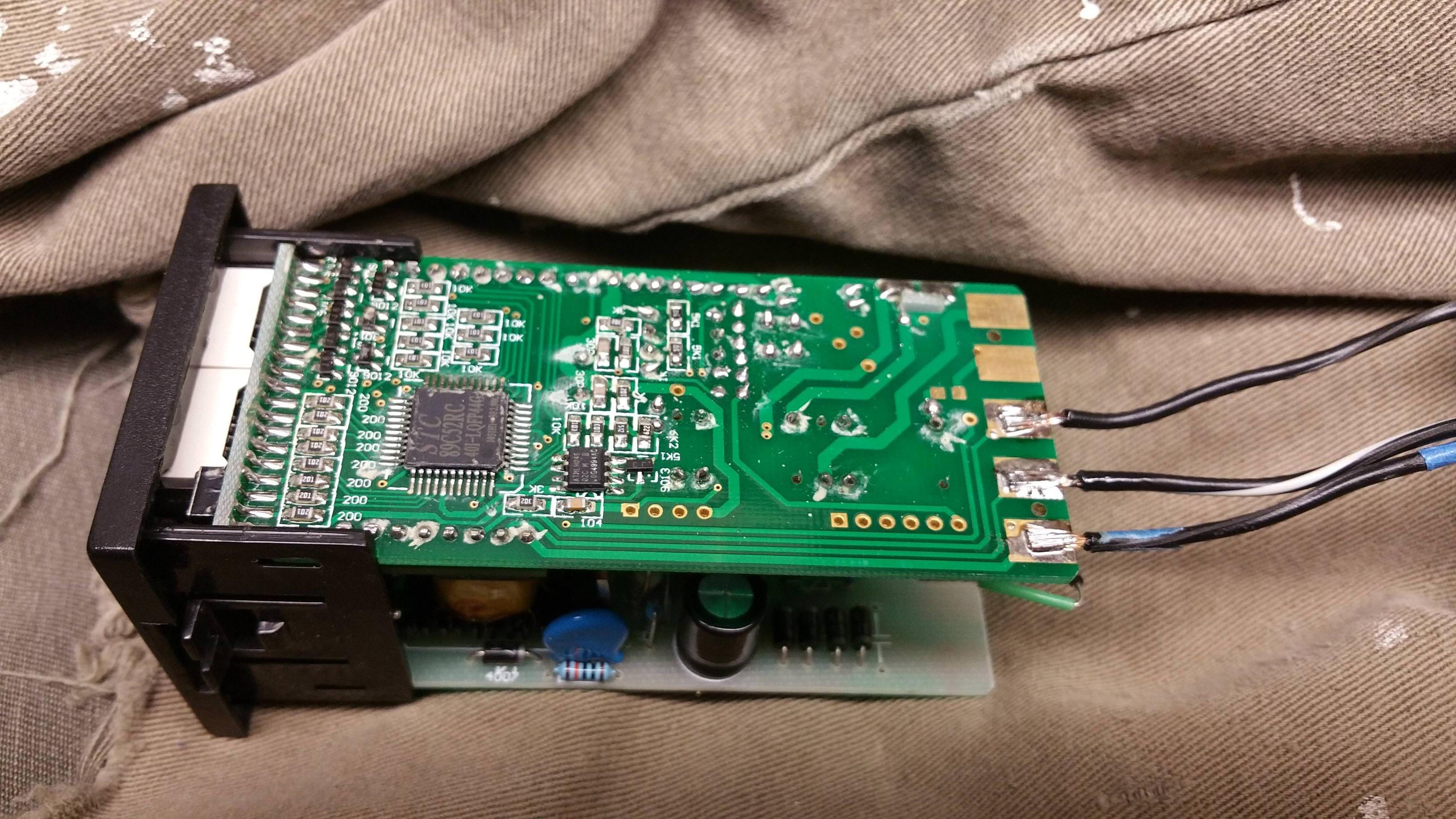

So this problem got really bad during the last brew. My temps were fluctuating about 30 degrees, and I found that wiggling the RTD's quick disconnects made the temps jump around. I began by getting rid of both quick disconnects and hard wiring (with solder) from the temperature sensor in RTD all the may to the screw connectors on the back of the PID. It was still very inconsistent, and up to 30 degree offsets were necessary. Wiggling the screw terminals on the PID made the temps fluctuate. At that point I said screw it, I'm soldering the wires to the circuit board inside the PID. The way the screw terminals make contact with the circuit board is questionable, at best. There is a delicate, spring loaded piece of metal that was slightly corroded on the back side of the screw terminal that rubs against a copper contact on the circuit board to make the connection. Not good.

Here is the result. The RTD wiring is one continuous run from the two leads on the sensor itself to the PID circuit board. Everything is soldered. No quick disconnects, no connectors, no crimp connectors, nothing. My offset is now zero and the RTD matches my Thermapen exactly. It is also much faster to respond (just as quick as the Thermapen) because I made sure that the sensor made good contact inside the body of the RTD by bending it 90 degrees. This allowed the sensor to push against the end of the probe. I also used new thermal paste.

What's scary about this is that in the blink of an eye, your temps can change a little bit or drastically, and there is really no way to know unless you notice the numbers on the PID jump.

Here is the result. The RTD wiring is one continuous run from the two leads on the sensor itself to the PID circuit board. Everything is soldered. No quick disconnects, no connectors, no crimp connectors, nothing. My offset is now zero and the RTD matches my Thermapen exactly. It is also much faster to respond (just as quick as the Thermapen) because I made sure that the sensor made good contact inside the body of the RTD by bending it 90 degrees. This allowed the sensor to push against the end of the probe. I also used new thermal paste.

What's scary about this is that in the blink of an eye, your temps can change a little bit or drastically, and there is really no way to know unless you notice the numbers on the PID jump.

Similar threads

- Replies

- 4

- Views

- 2K

- Replies

- 4

- Views

- 824

- Replies

- 11

- Views

- 787