AkTom

Well-Known Member

Just ordered the 10.5 and hop spider. Can’t wait.

The 240V is great! heating and ramp times are great and I get a nice consistent boil at 90% power on 240V.Mine delivered about a week ago. I have yet to unbox as I am wanting to get a 240v plug installed in my garage.

I’m still dialing this system in based on my processes to be more consistent and predictable. I’m a brand new brewer and now have 15 batches under my belt. mash/lauter efficiencies range from 75-78.5% depending on the grain bill and over the last 4 batches I’ve hit or slightly exceeded my OG by a point. I’m a big fan of ipas and NEIPAs so my grain boils have included 15-30% oats and wheat that make it pretty sticky too so I’m happy with it. Most importantly my wife likes the beer too!so is this thread not seeing any activity because the foundry is currently out of stock, no brewing going on, or has everybody just been able to figure everything they need out based on the info in the thread itself?

I’ve made 5 batches now with my 6.5. All 3 gallon batches. Comments:

- the support ring is a pita. It is very, very easy to dislodge and it happens all the time.

- the silicone gasket they put in the lid is another pita. It falls out constantly.

- my controller seems to have a mind of its own and rarely holds temp “within a degree” as they state. I set it for 152 and it goes to 160. I have to keep messing with it, lowering the temp to get it to stop.

- It performs like a biab system. I get lots of junk carried into my wort, despite running the pump back through the grain bed for the entire mash. I have taken to scooping out the trash manually with a fine strainer before I start the boil and this takes me a half hour.

- The 6.5 has about 1/2 gallon dead space and losses due to hops, waste and trub. Thats significant for a 3 gallon batch and I find I have to calculate my recipes as 4 gallon recipes to get 3 gallons out at the right gravity.

- Their wort chiller sucks. Its designed to hang on the lip of the kettle and only about 1/3 of it reaches the wort at 3 gallons. Takes FOREVER to cool. I use my other wort chiller instead.

- My finished beers have been decent, but not better or easier than anything I was making prior to buying this, despite the supposed exact temperature control.

- On the positive side, that little pump is the best thing ever. Super reliable, super quiet. You can’t even tell its running. That little clamp they give you to restrict the flow is cheap though and I have found it doesn’t work well.

I have ordered a hop spider basket to use with this is the future. I hope that will eliminate some of the waste. I am also going to try a grain bag inside the basket. Based on my experiences though, I am very afraid this will lead to stuck mash. I don’t know what I can do to make the controller stay at the temp its set at.

I wish that adapter came in a more normal plug arrangement. My 220v plugs have one vertical and one horizontal, not two horizontal.

My 220v wall outlet is the 20A variety. I am guessing that the 110v plug/wire is not the best to pair with a 20A plug? The unit will only pull what it needs, but I can not seem to find a 110v plug to 220v #6 plug adapter.

Looks like he has quite the hangover...

OMG - can't stop laughing. Never even noticed that.Looks like he has quite the hangover...

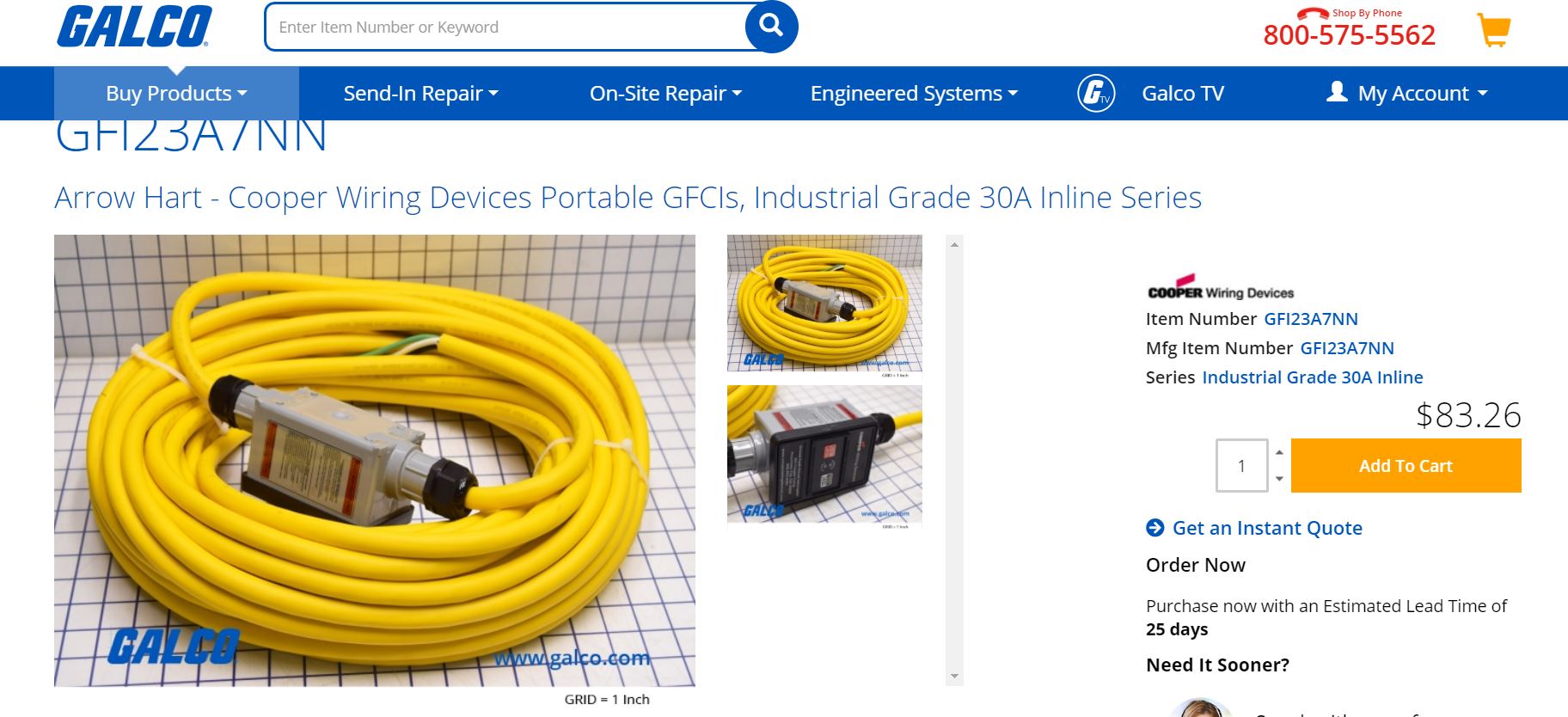

I changed mine to the 240 plug but was able to find an adapter like this. I don't know if they are available for every 240 plug configuration. I tried it out with the adapter at 120 and it worked fine. The only thing I was cautioned on is if I use 120, make sure when I go back to 240 be sure to switch the Foundry back to 240. 120 on the Foundry to a 240 outlet equals fried foundry. I have a 240 in my brew shed, so will rarely use the adapter but wanted the option to take the Foundry where 240 is not available. I am no electrician, so if anyone sees a problem with this, let me knowView attachment 677239

I’ve made 5 batches now with my 6.5. All 3 gallon batches. Comments:

- the support ring is a pita. It is very, very easy to dislodge and it happens all the time.

- the silicone gasket they put in the lid is another pita. It falls out constantly.

- my controller seems to have a mind of its own and rarely holds temp “within a degree” as they state. I set it for 152 and it goes to 160. I have to keep messing with it, lowering the temp to get it to stop.

- It performs like a biab system. I get lots of junk carried into my wort, despite running the pump back through the grain bed for the entire mash. I have taken to scooping out the trash manually with a fine strainer before I start the boil and this takes me a half hour.

- The 6.5 has about 1/2 gallon dead space and losses due to hops, waste and trub. Thats significant for a 3 gallon batch and I find I have to calculate my recipes as 4 gallon recipes to get 3 gallons out at the right gravity.

- Their wort chiller sucks. Its designed to hang on the lip of the kettle and only about 1/3 of it reaches the wort at 3 gallons. Takes FOREVER to cool. I use my other wort chiller instead.

- My finished beers have been decent, but not better or easier than anything I was making prior to buying this, despite the supposed exact temperature control.

- On the positive side, that little pump is the best thing ever. Super reliable, super quiet. You can’t even tell its running. That little clamp they give you to restrict the flow is cheap though and I have found it doesn’t work well.

I have ordered a hop spider basket to use with this is the future. I hope that will eliminate some of the waste. I am also going to try a grain bag inside the basket. Based on my experiences though, I am very afraid this will lead to stuck mash. I don’t know what I can do to make the controller stay at the temp its set at.

Got an email from Anvil today that the pumps are on back order until Mid-June, but Foundry orders will start shipping (without the pump) on May 18.

I have tried the malt basket alone, malt basket with a Wilser bag and just the Wilser bag alone with a Brewzilla false bottom. I am sticking with the false bottom and the Wilser bag. Great recirc flow, minimal sediment after the mash and easier cleanup. I am thinking Anvil should have gone with this approach from the beginning and ditched the malt basket (which looks like the legs will break over time anyway).

Mike made me a custom bag to work with the false bottom and it is really working out well.

I am 7 batches in with the 10.5 Foundry. I love it. Yes the ring is a pain and I stopped even bothering with the rubber gasket. Last few batches I have found that if I hold the ring with one hand and lift the malt pipe. half way out with the other, then the ring does not pop out when pulling the malt pipe the rest of the way. I use the 400 micron bag from The Brew Bag.

As someone who has been a BIAB brewer for 7-8 years now, sediment levels seem to be about the same as with a kettle, but my kettle ball valve was not sitting on bottom like the Foundry does. Seems that the valve on the unit should be maybe an inch higher up. Even with whirlpooling and then letting it settle and then turning the valve upward, you still get a lot of trub. Couple ideas I was thinking about to solve this was to either brew 6 gallon batches instead of 5.5 and then leave the valve facing down and then pumping off the first half gallon of sludge and then turning the valve up and draining the rest into my carboy, My other though was to just rack the beer off from the top down.

Does anyone have an issue with the ball valve coming loose from turning it do drain off? I make sure it's tight, but then the motion of turning it upward and then back down, seems to loosen the washer inside and it will start to leak out of the bottom.

I have 16 brews under my belt on the 10.5g foundry and have used the wilser bag inside the maltpipe for 14 of them and prefer the bag for sure to keep debris out of boil when crushing finer. I’ve been wanting to try the bag alone but couldnt find a false bottom that fits without spending and arm and leg for a custom false bottom. Which size FB do you have from the brewzilla? Can you purchase this separately? I’m intrigued by this if it help my mash efficiency but honestly my mash efficiency is now consistently in the 76-78% range depending on grain Bill. So while I’m very happy with this, always open to inprovingI have tried the malt basket alone, malt basket with a Wilser bag and just the Wilser bag alone with a Brewzilla false bottom. I am sticking with the false bottom and the Wilser bag. Great recirc flow, minimal sediment after the mash and easier cleanup. I am thinking Anvil should have gone with this approach from the beginning and ditched the malt basket (which looks like the legs will break over time anyway).

Mike made me a custom bag to work with the false bottom and it is really working out well.

You certainly have over 10x more brewing experience than I lol. Ive started my home-brew career with this 10.5g foundry. I will say that I have no clue what the anvil pump is rated for as far as temps but probably should know this myself. Occasionally, during the boil when it is starting and producing a nice foam, before I knew enough to simply lower the power to about 90% (Im on 240V), I simply ran the pump for a short bit at boiling to get rid of the foam. It worked and the pump never ceased but I only ran it for about a minute if that much. Nevertheless, I don't do that anymore because I simply lower the power to 90% to get a nice rolling and consistent boil. I will also say that this pump has worked flawlessly over my 16 batches brewed. I let all my hops roam free in the boil and whirlpool/steep and typically have about 6-7oz of hop pellets in the kettle before pumping to fermenter. when pumping the wort into the fermenter, even towards the end of filling the fermenter, the pump has zero issues when hops are coming through the pump. After done brewing, I simply do a CIP with PBW recirculating through the pump at 150degrees and the pump ALWAYS comes out squeaky clean as well. Although Ive never owned another pump, this pump simply works and works well for me with zero issues.Last but not least I normally use my pump after boiling is complete and run 212F wort through this for about 5 minutes to sanitize this before cooling and to help chilling instead of using a sanitized spoon and stirring. Based on something I read I'm guessing that their pumps are not rated for boiling. Can somebody confirm what temperature their pumps are rated for?

Thanks!

Paul

Here is the product on MoreBeer. I had to modify the legs to raise the false bottom so it would clear the foundry's spigot. Replacement Malt Pipe Boiler Screen for 35L Robobrew / BrewZilla | MoreBeerI have 16 brews under my belt on the 10.5g foundry and have used the wilser bag inside the maltpipe for 14 of them and prefer the bag for sure to keep debris out of boil when crushing finer. I’ve been wanting to try the bag alone but couldnt find a false bottom that fits without spending and arm and leg for a custom false bottom. Which size FB do you have from the brewzilla? Can you purchase this separately? I’m intrigued by this if it help my mash efficiency but honestly my mash efficiency is now consistently in the 76-78% range depending on grain Bill. So while I’m very happy with this, always open to inproving

Enter your email address to join: