wmubronco

Well-Known Member

Been brewing for 6 years now, made the switch from propane to 220V system, with 1/2bbl Chronical as my fermenter. Keep everything cleaned and sanitized between brews as well. Have my brewhouse efficiency at 65%.

Have since improved my efficiency, however noticed on most of my ales and IPAs, there's the estery taste. Initial guess is that I may be using too much Crystal in my recipes. I adjust my water chemistry to match the specific profile and hit my numbers.

Let's get back to the topic, AMBER ALERT! During brewday, at mashing, I went to add the 2nd addition of minerals and then all of a sudden... ***silence*** pumps go off and to my dismay the entire panel went out. Long story short, I had to rework my wiring that took about 1.5 hours to get everything back up and running, hence the name for this Amber... AMBER ALERT!

So basically my mash was stalled and temperature dropped a good 20degrees, if not more, before I got the panel back in action. Brewday continued and I hit 74% efficiency on the mash. Fermented 3 weeks at 64F, kegged, carbonated at 28psi for 4 days, then went for first pour....

Hmmm, doesn't taste right, a little sweet, definitely not right. Wondering if the huge 1.5 hour delay during the the mash had some effects. Previous brew was a Nut Brown Ale then I entered into a competition and got back tasting notes as vegetal (was first time I used a 1/2bbl keg to serve from - wish I cleaned like not other before using).

Comments/tips appreciated. Would like to see how I can also improve my ales/IPAs.

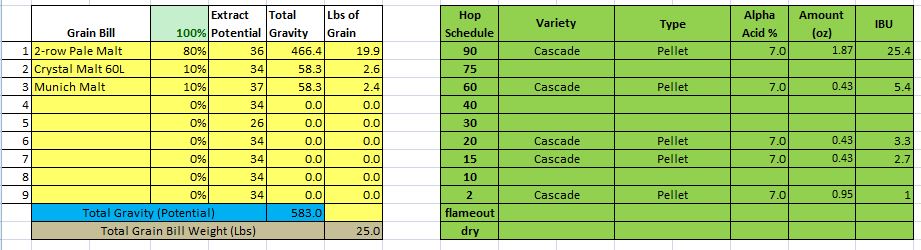

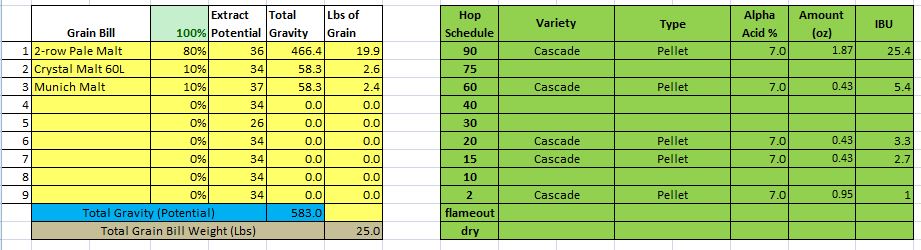

Attached a few of the previous recipes, and also water profile for my Amber Alert.

Have since improved my efficiency, however noticed on most of my ales and IPAs, there's the estery taste. Initial guess is that I may be using too much Crystal in my recipes. I adjust my water chemistry to match the specific profile and hit my numbers.

Let's get back to the topic, AMBER ALERT! During brewday, at mashing, I went to add the 2nd addition of minerals and then all of a sudden... ***silence*** pumps go off and to my dismay the entire panel went out. Long story short, I had to rework my wiring that took about 1.5 hours to get everything back up and running, hence the name for this Amber... AMBER ALERT!

So basically my mash was stalled and temperature dropped a good 20degrees, if not more, before I got the panel back in action. Brewday continued and I hit 74% efficiency on the mash. Fermented 3 weeks at 64F, kegged, carbonated at 28psi for 4 days, then went for first pour....

Hmmm, doesn't taste right, a little sweet, definitely not right. Wondering if the huge 1.5 hour delay during the the mash had some effects. Previous brew was a Nut Brown Ale then I entered into a competition and got back tasting notes as vegetal (was first time I used a 1/2bbl keg to serve from - wish I cleaned like not other before using).

Comments/tips appreciated. Would like to see how I can also improve my ales/IPAs.

Attached a few of the previous recipes, and also water profile for my Amber Alert.