You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Affligem Blond Clone?

- Thread starter davidkrau

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

A decade later I'm interested in a good Affligem Blond clone too!

I'm fermenting a Affligem Bond clone right now, I used this recipy:

http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf

I cultivated the yeast from a Affligem Blond bottle, made a 2 litre starter and used beet sugar instead of the candisyrup.

http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf

I cultivated the yeast from a Affligem Blond bottle, made a 2 litre starter and used beet sugar instead of the candisyrup.

I'm fermenting a Affligem Bond clone right now, I used this recipy:

http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf

I cultivated the yeast from a Affligem Blond bottle, made a 2 litre starter and used beet sugar instead of the candisyrup.

Interesting, might give that grain bill a try. I tried harvesting yeast from a bottle of Affligem a few months ago, but the yeast was dead. I assumed they'd pasteurized it. Might try again with a fresher bottle. Have you smelled/tased the starter to confirm its the primary yeast strain?

Interesting, might give that grain bill a try. I tried harvesting yeast from a bottle of Affligem a few months ago, but the yeast was dead. I assumed they'd pasteurized it. Might try again with a fresher bottle. Have you smelled/tased the starter to confirm its the primary yeast strain?

Yeast age may be an important factor indeed. Luckily I got my Affligem from a dutch supermarket which has a pretty short shelve life. Only after 4 days the yeast showed signs of life. On a dutch forum I read that it's not advised to feed it apple juice and the like so I started with a 200ml 1040 (extract)wort, 10% sugar and a little yeast nutrient on a stir plate and stirred vigorously for 4 hours, then continued stirring very slowly to keep the yeast in suspension. I repeated this with +400ml step and a +1400ml step to get a very active 2L starter. The 5 litre erlenmeyer I used for the 2 litre starter was not even big enough to hold the foam so I had to add a blow off.

My findings were that keeping the yeast in suspension is really important for it increases yeast growth quite a bit with this one.

It smelled a bit sour and sulfur but I did not taste it. On the dutch forum I was told the smell is supposed to be like that so I'm not that worried it's another strain. I know the brewery was bought by Heineken some time ago and hope they did not tinker with the yeast!

Yeast age may be an important factor indeed. Luckily I got my Affligem from a dutch supermarket which has a pretty short shelve life. Only after 4 days the yeast showed signs of life. On a dutch forum I read that it's not advised to feed it apple juice and the like so I started with a 200ml 1040 (extract)wort, 10% sugar and a little yeast nutrient on a stir plate and stirred vigorously for 4 hours, then continued stirring very slowly to keep the yeast in suspension. I repeated this with +400ml step and a +1400ml step to get a very active 2L starter. The 5 litre erlenmeyer I used for the 2 litre starter was not even big enough to hold the foam so I had to add a blow off.

My findings were that keeping the yeast in suspension is really important for it increases yeast growth quite a bit with this one.

It smelled a bit sour and sulfur but I did not taste it. On the dutch forum I was told the smell is supposed to be like that so I'm not that worried it's another strain. I know the brewery was bought by Heineken some time ago and hope they did not tinker with the yeast!

You're in Europe? I'm jealous. I heard many European breweries pasteurize before shipping across the pond to North America to extend shelf life. Will attempt again though.

You're in Europe? I'm jealous. I heard many European breweries pasteurize before shipping across the pond to North America to extend shelf life. Will attempt again though.

Pasteurize like in cooking? That Sounds horrific. Yes for belgian Beers its quite nice to live here. I noticed there was only a Small amount of sediment in the bottle compared to a Westmalle Tripel for instnce maybe you check with a Flash light First?

luckybeagle

Making sales and brewing ales.

Reviving this thread from the dead to ask one question...

bordev: how did it turn out? I'm attempting this exact recipe this week. A throwback to our year living in Haarlem (and buying this beer a dozen times at Albert Heijn). Where are you at?

bordev: how did it turn out? I'm attempting this exact recipe this week. A throwback to our year living in Haarlem (and buying this beer a dozen times at Albert Heijn). Where are you at?

Leonie Hill

Member

- Joined

- Mar 31, 2019

- Messages

- 9

- Reaction score

- 3

I’m in France at the moment. Affligem Blond is massively popular here - and I understand why! It is a great beer! I live in Singapore and will try to brew a clone once back. Keen on learning from others who have brewed this beer. Any tips?

luckybeagle

Making sales and brewing ales.

Hi Leonie,

Glad you found it and like it!

The clone recipe I brewed a couple months ago is an approximation (http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf), but I think the yeast might be a little different than what CSI recommends). I'm really not sure; it has been a year since I moved back to the US from the Netherlands, and despite drinking dozens of bottles of this over the year I was there, I honestly can't remember what it tastes like (just that I liked it!). I brewed it because I was trying to chase the feeling of sitting in a crowded plaza in Delft with my wife on a warm summer day, just before we moved home:

Color was spot on, and it was nice and effervescent, yet smooth. I think the only big tip I have over what CSI recommended in their recipe is that it might be best to leave it in primary for two weeks instead of 5 or 6 days, then rack to secondary and cold condition. CSI has good reasoning for why you want to get the beer off the yeast cake before too long, but I know that there's a lot of opinions around that so I'll just say I followed the recipe without experimenting myself. I'd probably opt for bottling this one if I were to brew it again (I kegged it and blew through too much of it before it really came together, flavorwise). Cold condition, fine with gelatin, bottle with a fresh pitch of yeast and store for 2 or 3 weeks before opening your first one. Then pop them all in the fridge before the flavor degrades!

The Styrian Goldings addition was pretty strong, but they softened around a month in. Maybe cutting back on these aroma hops would also be a good idea. I've always found those hops to be a little pungent and funky, and neither of those descriptors are what would use to describe the real Affligem. Still, after 4 or 5 weeks it tasted great in the keg!

Glad you found it and like it!

The clone recipe I brewed a couple months ago is an approximation (http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf), but I think the yeast might be a little different than what CSI recommends). I'm really not sure; it has been a year since I moved back to the US from the Netherlands, and despite drinking dozens of bottles of this over the year I was there, I honestly can't remember what it tastes like (just that I liked it!). I brewed it because I was trying to chase the feeling of sitting in a crowded plaza in Delft with my wife on a warm summer day, just before we moved home:

Color was spot on, and it was nice and effervescent, yet smooth. I think the only big tip I have over what CSI recommended in their recipe is that it might be best to leave it in primary for two weeks instead of 5 or 6 days, then rack to secondary and cold condition. CSI has good reasoning for why you want to get the beer off the yeast cake before too long, but I know that there's a lot of opinions around that so I'll just say I followed the recipe without experimenting myself. I'd probably opt for bottling this one if I were to brew it again (I kegged it and blew through too much of it before it really came together, flavorwise). Cold condition, fine with gelatin, bottle with a fresh pitch of yeast and store for 2 or 3 weeks before opening your first one. Then pop them all in the fridge before the flavor degrades!

The Styrian Goldings addition was pretty strong, but they softened around a month in. Maybe cutting back on these aroma hops would also be a good idea. I've always found those hops to be a little pungent and funky, and neither of those descriptors are what would use to describe the real Affligem. Still, after 4 or 5 weeks it tasted great in the keg!

I need try harvesting Affligem yeast again. As per my above comments, I failed in the past but worst case scenario I still get to drink a few delicious beers.

Leonie Hill

Member

- Joined

- Mar 31, 2019

- Messages

- 9

- Reaction score

- 3

Hi Leonie,

Glad you found it and like it!

The clone recipe I brewed a couple months ago is an approximation (http://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf), but I think the yeast might be a little different than what CSI recommends). I'm really not sure; it has been a year since I moved back to the US from the Netherlands, and despite drinking dozens of bottles of this over the year I was there, I honestly can't remember what it tastes like (just that I liked it!). I brewed it because I was trying to chase the feeling of sitting in a crowded plaza in Delft with my wife on a warm summer day, just before we moved home:

View attachment 645216

Color was spot on, and it was nice and effervescent, yet smooth. I think the only big tip I have over what CSI recommended in their recipe is that it might be best to leave it in primary for two weeks instead of 5 or 6 days, then rack to secondary and cold condition. CSI has good reasoning for why you want to get the beer off the yeast cake before too long, but I know that there's a lot of opinions around that so I'll just say I followed the recipe without experimenting myself. I'd probably opt for bottling this one if I were to brew it again (I kegged it and blew through too much of it before it really came together, flavorwise). Cold condition, fine with gelatin, bottle with a fresh pitch of yeast and store for 2 or 3 weeks before opening your first one. Then pop them all in the fridge before the flavor degrades!

The Styrian Goldings addition was pretty strong, but they softened around a month in. Maybe cutting back on these aroma hops would also be a good idea. I've always found those hops to be a little pungent and funky, and neither of those descriptors are what would use to describe the real Affligem. Still, after 4 or 5 weeks it tasted great in the keg!

Hi LuckyBeagle,

I am so sorry for the late reply. Once I was back in Singapore I was back to normal family routines hence forgot to reply.

I really appreciate your help and guidance. I will brew this beer next time I'm going to brew. I currently have a German Pilsner fermenting in my wine fridge, but once done then I'll brew this clone.

Once again - thanks a lot for your help.

Brgds

LeonieHill

luckybeagle

Making sales and brewing ales.

Five years on and I'm finally going to rebrew this. My equipment and knowledge (and patience!) is better now, so I think the odds of success are much better this go around. IIRC, I rushed the last one, had mash issues, and sped through conditioning. Shame, shame.

Might as well revive this thread from the dead and document the process fully. Could be fun and informative, right?

System: 16 gallon 3 vessel 240V eHERMS

Recipe:

76% Weyermann Pilsner Malt

16% Munich 10L

8% Dextrose (Corn Sugar)

13 IBU Mittelfruh at 60

8.5 IBU Spalt at 30

4.5 IBU Styrian Golding at 15

Yeast: WY1388 + Starter

0.80M cells / mL / °P (1.2L starter, approx)

OG: 1.064

SRM: 5.9

IBU: 26

Water: Ca: 50, Mg: 5, Na: 5, SO4: 55, Cl: 70 (BrunWater Yellow Full) - salts as needed + potassium metabisulfite for chlorine neutralization.

Mash pH 5.4 (adjusted as needed with lactic acid, per brewersfriend advanced water calc)

Fermentation: 65 pitch, ramped to 75F over 1 week, then chilled once reaching FG to 50F for 2 weeks' conditioning via DIY glycol chiller before kegging (sorry, I know it's less authentic, but this beer is routinely on tap in the Netherlands so I don't think it's a huge violation.

Notes and process:

Mash temp held at 150F for minimum 1 hour--likely several. I recirculate the entire time, keeping temperature stable via pumping through a HERMS coil and using a PID controller for the element in the HLT (Auber cube 2E). I also do full volume, no sparge mashes as my efficiency is fine at ~75%, but I save tons of time by not fly sparging. For me, I don't see benefit in getting 85% efficiency or so if I have to babysit the system in order to achieve it. With my method, the pH never drops, and I end up with crystal clear wort and reasonable efficiency from recirculating anywhere from 1-6 hours while I go about my day.

I'm also using dextrose instead of candisyrup. I never buy clear candisyrup, but am taking to heart an exBEERiment I read regarding dextrose vs my longstanding go-to of table sugar (sucrose). The experiment concluded there was a very perceptible difference in side-by-side tastings between the two--the sucrose one had a harsher bitterness, and it sounds like others have experienced this same outcome. Since this beer holds a special place in my heart, I might as well do everything I can to make an approachable, soft, malty yet lively Blond. Maybe I'll pull it off and it'll transport me back to that lovely square in Delft in 2018, or the seaside restaurant in Zandvoort from our visit in 2023:

I'll grab ingredients for this tomorrow, get cracking on the starter, and brew it this weekend, with full photos and process documentation. After all: What we measure, we manage!

Might as well revive this thread from the dead and document the process fully. Could be fun and informative, right?

System: 16 gallon 3 vessel 240V eHERMS

Recipe:

76% Weyermann Pilsner Malt

16% Munich 10L

8% Dextrose (Corn Sugar)

13 IBU Mittelfruh at 60

8.5 IBU Spalt at 30

4.5 IBU Styrian Golding at 15

Yeast: WY1388 + Starter

0.80M cells / mL / °P (1.2L starter, approx)

OG: 1.064

SRM: 5.9

IBU: 26

Water: Ca: 50, Mg: 5, Na: 5, SO4: 55, Cl: 70 (BrunWater Yellow Full) - salts as needed + potassium metabisulfite for chlorine neutralization.

Mash pH 5.4 (adjusted as needed with lactic acid, per brewersfriend advanced water calc)

Fermentation: 65 pitch, ramped to 75F over 1 week, then chilled once reaching FG to 50F for 2 weeks' conditioning via DIY glycol chiller before kegging (sorry, I know it's less authentic, but this beer is routinely on tap in the Netherlands so I don't think it's a huge violation.

Notes and process:

Mash temp held at 150F for minimum 1 hour--likely several. I recirculate the entire time, keeping temperature stable via pumping through a HERMS coil and using a PID controller for the element in the HLT (Auber cube 2E). I also do full volume, no sparge mashes as my efficiency is fine at ~75%, but I save tons of time by not fly sparging. For me, I don't see benefit in getting 85% efficiency or so if I have to babysit the system in order to achieve it. With my method, the pH never drops, and I end up with crystal clear wort and reasonable efficiency from recirculating anywhere from 1-6 hours while I go about my day.

I'm also using dextrose instead of candisyrup. I never buy clear candisyrup, but am taking to heart an exBEERiment I read regarding dextrose vs my longstanding go-to of table sugar (sucrose). The experiment concluded there was a very perceptible difference in side-by-side tastings between the two--the sucrose one had a harsher bitterness, and it sounds like others have experienced this same outcome. Since this beer holds a special place in my heart, I might as well do everything I can to make an approachable, soft, malty yet lively Blond. Maybe I'll pull it off and it'll transport me back to that lovely square in Delft in 2018, or the seaside restaurant in Zandvoort from our visit in 2023:

I'll grab ingredients for this tomorrow, get cracking on the starter, and brew it this weekend, with full photos and process documentation. After all: What we measure, we manage!

mashpaddled

Well-Known Member

I'm not sure if the Duvel strain is the right choice; however, it's used quite a bit around Belgian breweries and fermenting at different temperatures and pitch rates can produce different character.

The westmalle strain could be another direction to attempt.

The westmalle strain could be another direction to attempt.

@luckybeagle it seems you have a great approach. From earlier in the thread, I would like to know if the yeast in the bottle was the fermentation strain or not. The grain bill would seem quite simple for this beer. The yeast is the key component. I had this beer for the first time in Brussels and it was very full flavored yet as usual for Belgian beers, very well attenuated. As you state, I would stay in beta until you get to 90-95% of pre-boil gravity to ensure this attenuation.

I have been using Gnome which is making a very nice beer. I think it might be the Achouffe yeast but anyway, I have not liked the usual suspects - 3787 or the Chimay yeast for trying to replicate this style. It would be awesome if the bottles actually contained the fermentation strain as this would take care of the largest question mark. Odds are it is not, but one never knows at our level.

Another thing to consider is pressure fermentation. I made one at 30PSI and it captured the mouthfeel but the esters were a bit too muted. I would think the tanks for Affligem are fairly large for the distribution amount which tells me they have some decent hydrostatic pressure in their fermenters. My next try will be at 5 PSI. I will see how that turns out. Fun to chase but the yeast is the key and I have accepted that I will just make something similar but good!

I have been using Gnome which is making a very nice beer. I think it might be the Achouffe yeast but anyway, I have not liked the usual suspects - 3787 or the Chimay yeast for trying to replicate this style. It would be awesome if the bottles actually contained the fermentation strain as this would take care of the largest question mark. Odds are it is not, but one never knows at our level.

Another thing to consider is pressure fermentation. I made one at 30PSI and it captured the mouthfeel but the esters were a bit too muted. I would think the tanks for Affligem are fairly large for the distribution amount which tells me they have some decent hydrostatic pressure in their fermenters. My next try will be at 5 PSI. I will see how that turns out. Fun to chase but the yeast is the key and I have accepted that I will just make something similar but good!

Strange to hear people are wanting to clone affligem, i am from belgium, and here it is seen as a industrial blond beer that is nothing special and is mainly sold to the Netherlands and tourists, but if you like it brew it!, i presume your version is probably better than the real thing.

My wife fell in love with it when we visited Belgium and the Netherlands, so I brewed an approximation which she also loves. I think it's just OK (both the real thing and my version).Strange to hear people are wanting to clone affligem, i am from belgium, and here it is seen as a industrial blond beer that is nothing special and is mainly sold to the Netherlands and tourists, but if you like it brew it!, i presume your version is probably better than the real thing.

Ha, that is funny! I picked it out of the 1000 beer menu list and really liked its flavor. My favorite Belgian beer is Tripel Karmeliet. @Jeroen79 what are some of your favorite blonde beers from your homeland? I would like to try them if I get the chance.Strange to hear people are wanting to clone affligem, i am from belgium, and here it is seen as a industrial blond beer that is nothing special and is mainly sold to the Netherlands and tourists, but if you like it brew it!, i presume your version is probably better than the real thing.

Some i like are, Chimay (White,Blue or Green), Chouffe houblon, Westmalle tripel, Vliet, Straffe hendrik, Rochefort 10, Geuze Boon Marriage parfait, ...

But there are so many more, and i always try something new if i see it on a menu.

But there are so many more, and i always try something new if i see it on a menu.

Thanks. Yes, so many choices in Belgium. I guess the blonde category is viewed as kind of boring in comparison to everything else. Anyway, Affligem Blonde drinks like a well made beer and is a treat in comparison to many American beers.

luckybeagle

Making sales and brewing ales.

Jeroen! I think we're friends on IG--I am "hoodwinkedbrewing" over there, and I believe you live in Tiel? I have family in Tiel. Small world. I might've mentioned that to you forever ago, but maybe I sent you that message in my head instead of through the app, haha.

It really is! It's also about the memories paired to it--chasing that nostalgic dragon Then again I also think Hertog Jan makes some great beers (The Grand Prestige is cheap and mass produced... and also delicious).

Then again I also think Hertog Jan makes some great beers (The Grand Prestige is cheap and mass produced... and also delicious).

Interesting; I've never considered (and now no longer have the ability to conduct a) pressure fermentation--I got rid of my Fermzillas after scratches and multiple infected batches. But I've been curious--sometimes the esters are a little too wild for me in Belgians, so being able to dial down their expressions would be nice. For now I'll just rely on ruling over fermentation temperature with an iron fist, haha.

That's a good observation. I'm pretty burned out on 3787 after having brewed with it a dozen or more times and only really being pleased with one or two. I know it's wildly popular and the go-to Belgian/trappist strain, especially for homebrewers, but I've enjoyed 3522 Ardennes (Achouffe strain) more consistently in my Belgians--at least for blonds and tripels. Chimay falls somewhere in the middle of the two for me.1388 Duvel does seem like an odd choice for an Affligem clone, but Candisyrup has been testing it in their clones/approximations of Affligem beers and seems like a nice starting point to get a highly attenuated beer that retains some malt sweetness without being too expressive when fermented on the lower end. Well, they use WLP570, but that's supposedly the same:

https://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf

Thanks. Yes, so many choices in Belgium. I guess the blonde category is viewed as kind of boring in comparison to everything else. Anyway, Affligem Blonde drinks like a well made beer and is a treat in comparison to many American beers.

It really is! It's also about the memories paired to it--chasing that nostalgic dragon

Another thing to consider is pressure fermentation. I made one at 30PSI and it captured the mouthfeel but the esters were a bit too muted. I would think the tanks for Affligem are fairly large for the distribution amount which tells me they have some decent hydrostatic pressure in their fermenters. My next try will be at 5 PSI. I will see how that turns out. Fun to chase but the yeast is the key and I have accepted that I will just make something similar but good!

Interesting; I've never considered (and now no longer have the ability to conduct a) pressure fermentation--I got rid of my Fermzillas after scratches and multiple infected batches. But I've been curious--sometimes the esters are a little too wild for me in Belgians, so being able to dial down their expressions would be nice. For now I'll just rely on ruling over fermentation temperature with an iron fist, haha.

I'm not sure if the Duvel strain is the right choice; however, it's used quite a bit around Belgian breweries and fermenting at different temperatures and pitch rates can produce different character.

The westmalle strain could be another direction to attempt.

That's a good observation. I'm pretty burned out on 3787 after having brewed with it a dozen or more times and only really being pleased with one or two. I know it's wildly popular and the go-to Belgian/trappist strain, especially for homebrewers, but I've enjoyed 3522 Ardennes (Achouffe strain) more consistently in my Belgians--at least for blonds and tripels. Chimay falls somewhere in the middle of the two for me.1388 Duvel does seem like an odd choice for an Affligem clone, but Candisyrup has been testing it in their clones/approximations of Affligem beers and seems like a nice starting point to get a highly attenuated beer that retains some malt sweetness without being too expressive when fermented on the lower end. Well, they use WLP570, but that's supposedly the same:

https://www.candisyrup.com/uploads/6/0/3/5/6035776/affligem_blonde_-_040.pdf

Good stuff. I picked up a Kegmenter used for $100 and it is a great pressure fermenter. I do think it is a missing lever when trying to clone commercial beers because they usually deal with even more pressure than 1-2 bar. It definitely affects the flavor profile and allows for some dialing down of things for a cleaner presentation.

Five years on and I'm finally going to rebrew this. My equipment and knowledge (and patience!) is better now, so I think the odds of success are much better this go around. IIRC, I rushed the last one, had mash issues, and sped through conditioning. Shame, shame.

Might as well revive this thread from the dead and document the process fully. Could be fun and informative, right?

System: 16 gallon 3 vessel 240V eHERMS

Recipe:

76% Weyermann Pilsner Malt

16% Munich 10L

8% Dextrose (Corn Sugar)

13 IBU Mittelfruh at 60

8.5 IBU Spalt at 30

4.5 IBU Styrian Golding at 15

Yeast: WY1388 + Starter

0.80M cells / mL / °P (1.2L starter, approx)

OG: 1.064

SRM: 5.9

IBU: 26

Water: Ca: 50, Mg: 5, Na: 5, SO4: 55, Cl: 70 (BrunWater Yellow Full) - salts as needed + potassium metabisulfite for chlorine neutralization.

Mash pH 5.4 (adjusted as needed with lactic acid, per brewersfriend advanced water calc)

Fermentation: 65 pitch, ramped to 75F over 1 week, then chilled once reaching FG to 50F for 2 weeks' conditioning via DIY glycol chiller before kegging (sorry, I know it's less authentic, but this beer is routinely on tap in the Netherlands so I don't think it's a huge violation.

Notes and process:

Mash temp held at 150F for minimum 1 hour--likely several. I recirculate the entire time, keeping temperature stable via pumping through a HERMS coil and using a PID controller for the element in the HLT (Auber cube 2E). I also do full volume, no sparge mashes as my efficiency is fine at ~75%, but I save tons of time by not fly sparging. For me, I don't see benefit in getting 85% efficiency or so if I have to babysit the system in order to achieve it. With my method, the pH never drops, and I end up with crystal clear wort and reasonable efficiency from recirculating anywhere from 1-6 hours while I go about my day.

I'm also using dextrose instead of candisyrup. I never buy clear candisyrup, but am taking to heart an exBEERiment I read regarding dextrose vs my longstanding go-to of table sugar (sucrose). The experiment concluded there was a very perceptible difference in side-by-side tastings between the two--the sucrose one had a harsher bitterness, and it sounds like others have experienced this same outcome. Since this beer holds a special place in my heart, I might as well do everything I can to make an approachable, soft, malty yet lively Blond. Maybe I'll pull it off and it'll transport me back to that lovely square in Delft in 2018, or the seaside restaurant in Zandvoort from our visit in 2023:

View attachment 841831

I'll grab ingredients for this tomorrow, get cracking on the starter, and brew it this weekend, with full photos and process documentation. After all: What we measure, we manage!

View attachment 841832

Good luck with the project, looks like a fun one.

Your decision to go with dextrose instead of table sugar stood out to me, and I appreciated the followup explanation that it was based on the results of a Brulosophy experiment. Admittedly, I haven't read that article yet and I probably should, but I'm wondering if they have it right (that table sugar results in harsher bitterness). I mean, it does (in a way), but I don't think it's the only variable or even a primary one. Since dextrose is going to leave unfermentable dextrins that help round out the flavor, it's just doing what a higher mash temp and low attenuation yeast would naturally achieve. High mash pH and low sulphate levels would also be top of the list. Just my two cents, so take it for what it's worth.

Huh? You must be thinking of some kind of dextrine malt. Dextrose is a pure monosaccharide. Also known as glucose. Table sugar (sucrose) is a disaccharide (one glucose and one fructose). The yeast have to work ever so slightly harder to ferment sucrose compared to dextrose.Since dextrose is going to leave unfermentable dextrins that help round out the flavor

Huh? You must be thinking of some kind of dextrine malt. Dextrose is a pure monosaccharide. Also known as glucose. Table sugar (sucrose) is a disaccharide (one glucose and one fructose). The yeast have to work ever so slightly harder to ferment sucrose compared to dextrose.

You're right. I had been thinking that it was less fermentable because more by weight is needed. That part of my post can be disregarded.

luckybeagle

Making sales and brewing ales.

All good homies. I talked with my friend at the LHBS about it this afternoon when I was picking up ingredients. He echoed what mac_1103 said above, regarding the easier ferment with dextrose vs glucose/fructose due to its simpler a purer nature, but neither of us were quite sure how/why a beer might turn out more harsh with sucrose. Maybe because it degrades yeast cell health with the extra labor and spins some off-flavors earlier on? I have no idea.

Maybe it's like a weightlifter who goes for a heavy benchpress sets and follows up with some simple pushups, vs the guy who just goes straight to pushups and doesn't prematurely fatigue himself with heavier weights. I'd be curious to learn more about why the dextrose experiments yield a softer end product. Maybe the absence of fructose makes for less likelihood of a cidery quality.

Here are the articles I am basing the decision to use dextrose on:

https://brulosophy.com/2020/08/10/s...s-dextrose-in-double-ipa-exbeeriment-results/

https://brulosophy.com/2019/02/25/sugar-additions-dextrose-vs-sucrose-exbeeriment-results/

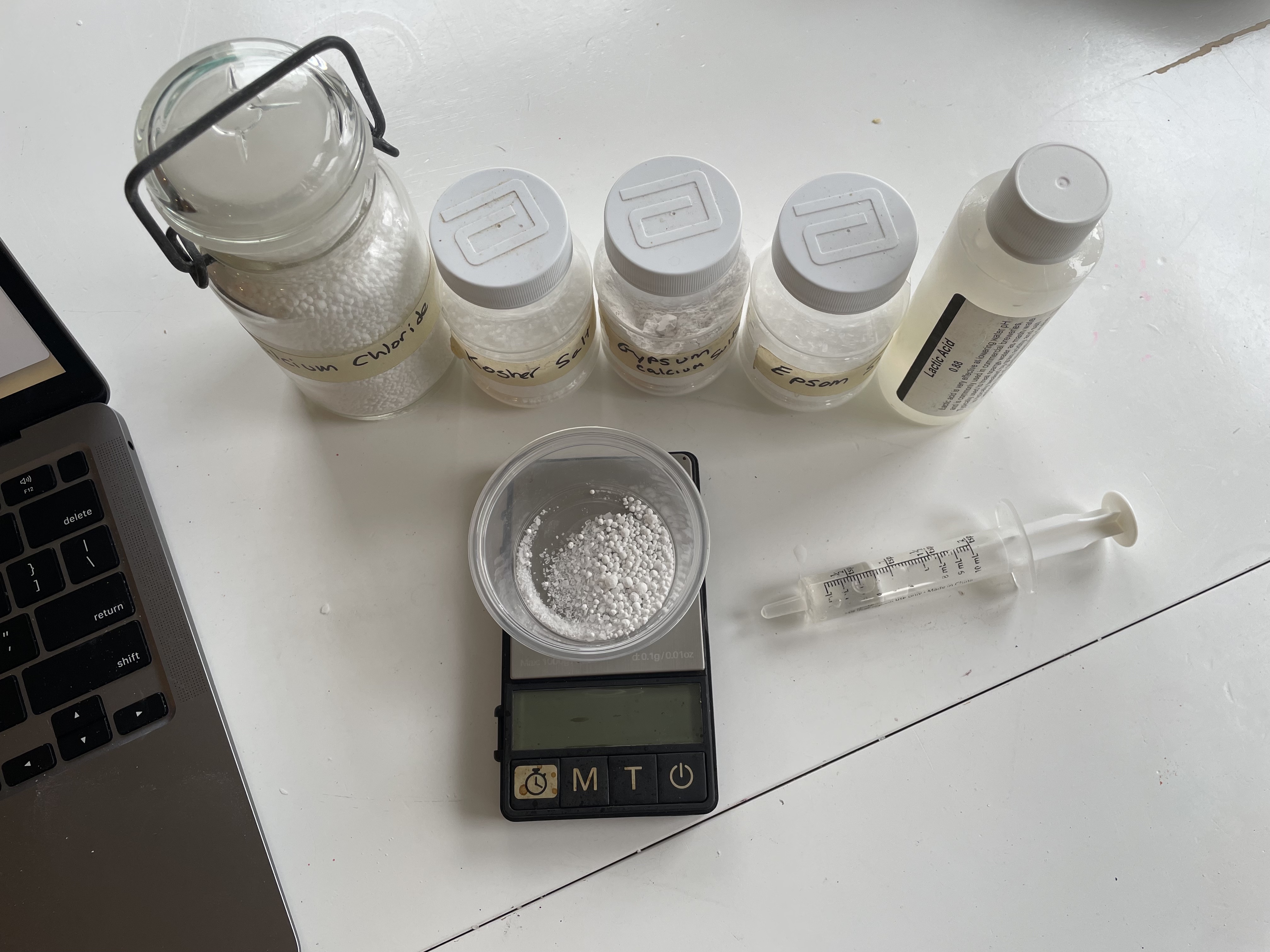

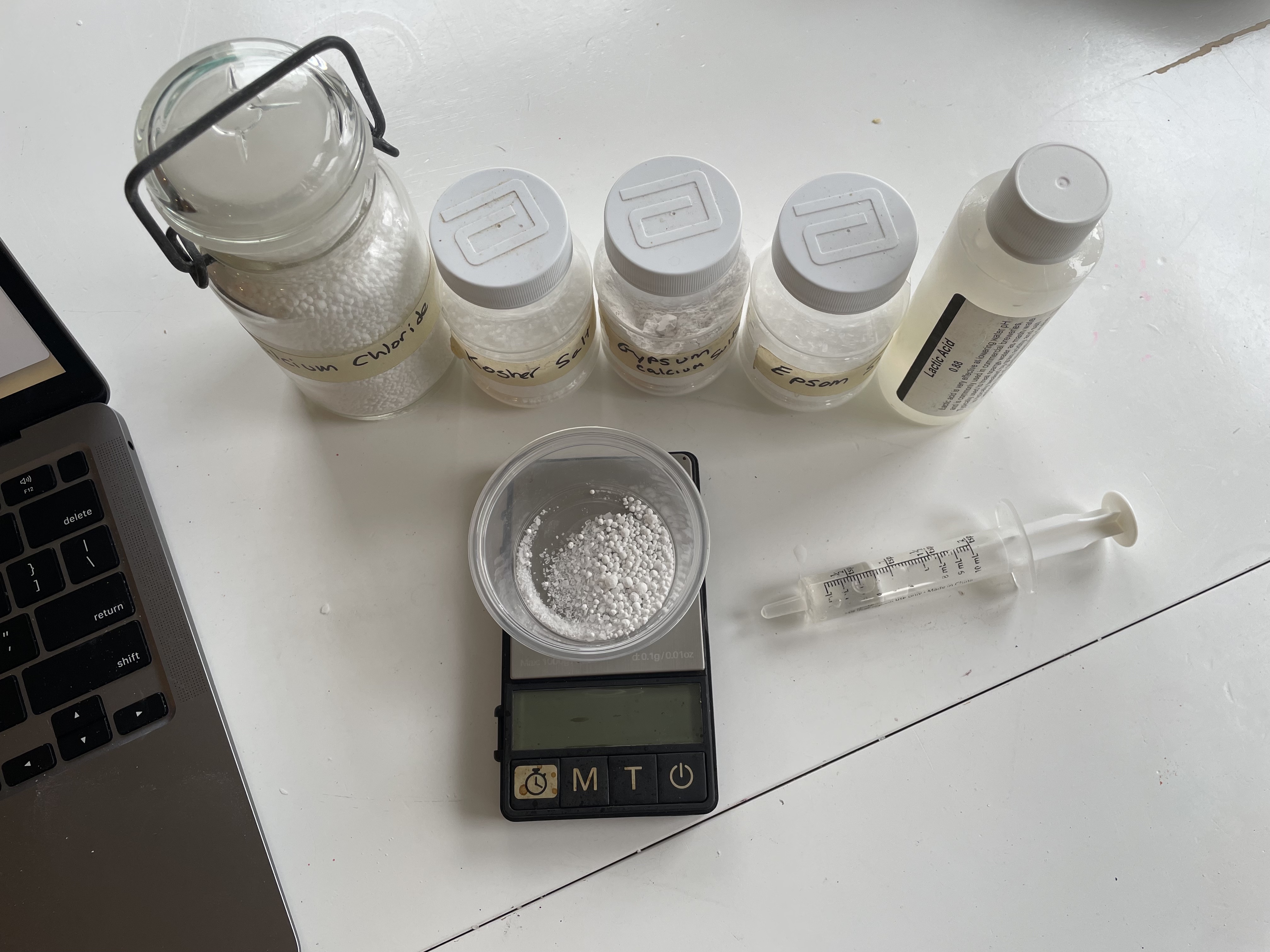

Today I grabbed supplemental ingredients as planned, and began a 1.5L starter of 1388. I've got a big bag of Weyermann Pilsner and various hops to complete the recipe which aren't pictured, though I am making one substitution and am opting for Munich Type I (6L) over my Munich 10L indication in the recipe mentioned earlier. No other alterations will be made, though.

Denny Conn, a member of our local homebrew club, presented on the "Shaken, Not Stirred" method of yeast cell cultivation at last November's meeting and made a believer out of me, so I'm opting for that method this time. So I'm giving the Erlenmeyer and the stirplate a break on this batch. Here's the basis of his presentation and argument:

https://www.experimentalbrew.com/2020/12/09/shaken-not-stirred-the-stir-plate-myth-buster/

Don't knock the dirty stove or the kid lunchbags. Cleaning and sorting with young children is futile beyond a certain extent.

I'll likely brew Saturday and will update with brew day photos and notes.

Maybe it's like a weightlifter who goes for a heavy benchpress sets and follows up with some simple pushups, vs the guy who just goes straight to pushups and doesn't prematurely fatigue himself with heavier weights. I'd be curious to learn more about why the dextrose experiments yield a softer end product. Maybe the absence of fructose makes for less likelihood of a cidery quality.

Here are the articles I am basing the decision to use dextrose on:

https://brulosophy.com/2020/08/10/s...s-dextrose-in-double-ipa-exbeeriment-results/

https://brulosophy.com/2019/02/25/sugar-additions-dextrose-vs-sucrose-exbeeriment-results/

Today I grabbed supplemental ingredients as planned, and began a 1.5L starter of 1388. I've got a big bag of Weyermann Pilsner and various hops to complete the recipe which aren't pictured, though I am making one substitution and am opting for Munich Type I (6L) over my Munich 10L indication in the recipe mentioned earlier. No other alterations will be made, though.

Denny Conn, a member of our local homebrew club, presented on the "Shaken, Not Stirred" method of yeast cell cultivation at last November's meeting and made a believer out of me, so I'm opting for that method this time. So I'm giving the Erlenmeyer and the stirplate a break on this batch. Here's the basis of his presentation and argument:

https://www.experimentalbrew.com/2020/12/09/shaken-not-stirred-the-stir-plate-myth-buster/

Don't knock the dirty stove or the kid lunchbags. Cleaning and sorting with young children is futile beyond a certain extent.

I'll likely brew Saturday and will update with brew day photos and notes.

Last edited:

I think your are mistaken, i am not on IG, and i don't live in Tiel, i actualy even have no idea where Tiel isJeroen! I think we're friends on IG--I am "hoodwinkedbrewing" over there, and I believe you live in Tiel? I have family in Tiel. Small world. I might've mentioned that to you forever ago, but maybe I sent you that message in my head instead of through the app, haha.

I'm not sure I buy that either, Brulosophy experiments or not. Wort contains sucrose and fructose anyway. Utilizing sucrose is one more enzymatic step, and the enzyme that does it is present in the yeast all the time.neither of us were quite sure how/why a beer might turn out more harsh with sucrose. Maybe because it degrades yeast cell health with the extra labor and spins some off-flavors earlier on? I have no idea.

luckybeagle

Making sales and brewing ales.

I had a whole post written up about today's brew day, with tons of details, but I accidentally swiped left on my trackpad and lost EVERYTHING.

So please pardon this short recap.

It was a good brew day. Here were my stats

OG: 1.062 (target 1.064)

Water chemistry: Yellow balanced

Ca: 55

Mg: 4.8

Na: 22

Cl: 65

SO4: 75

Mash ph: 5.4 (used 4ml lactic acid).

Doughed in at 3:00pm to hit a strike temperature of 150F. I then recirculated through my HERMS coil, which sits in a PID-controlled hot liquor with a 5500w element. I do full-volume mashes, I don't sparge (I can't justify the extra involvement for 5-10% more efficiency), and I often recirculate the mash for hours. Today my total mash time was 4 hours for an efficiency of about 75%. For me, it's a set-it-and-get-to-it-when-you-can process. No temperature drop, no pH change--just crystal clear wort after what is essentially a perpetual vorlauf.

This atypical process was borne out of necessity--if I was still using an igloo cooler and natural gas, I'd need to be way more hands-on with the process, which is hard to find time for, and would result in me getting to brew far less often.

[

[

Anyway, after mashing, I took a preboil gravity reading and hit 1.049. This is BEFORE adding the dextrose.

I pumped the wort over to the BK and used a hop spider to catch any chunks of grain that didn't settle into the grain bed/got pushed over through the pump. I then brought it up to a boil, added my 60 minute addition of Mittelfruh, and promptly cleaned my MLT out. The Mittelfruh looked awesome--so bright!

I then lidded the kettle, turned on the steam condenser, and proceeded with a pretty business-as-usual boil--adding Spalt at 30, and EKG at 15 (I thought I had a big bag of Styrian but couldn't find it, so I was forced to substitute! Should be OK, though). I also added the 1 LB bag of dextrose at about 15 minutes, some yeast nutrient, and began recirculating the boiling wort through my pumps, counterflow chiller and hoses to sanitize everything. What a mess of hoses it is! But it works. Also, as an aside, the DIY steam condenser is 1000% worth it and is my favorite piece of equipment--I can brew without fogging up the garage or having to roll the doors up.

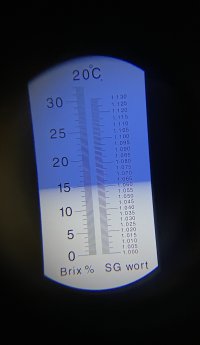

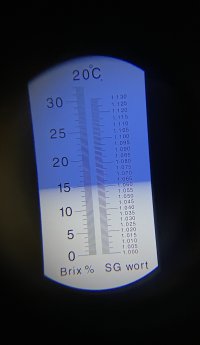

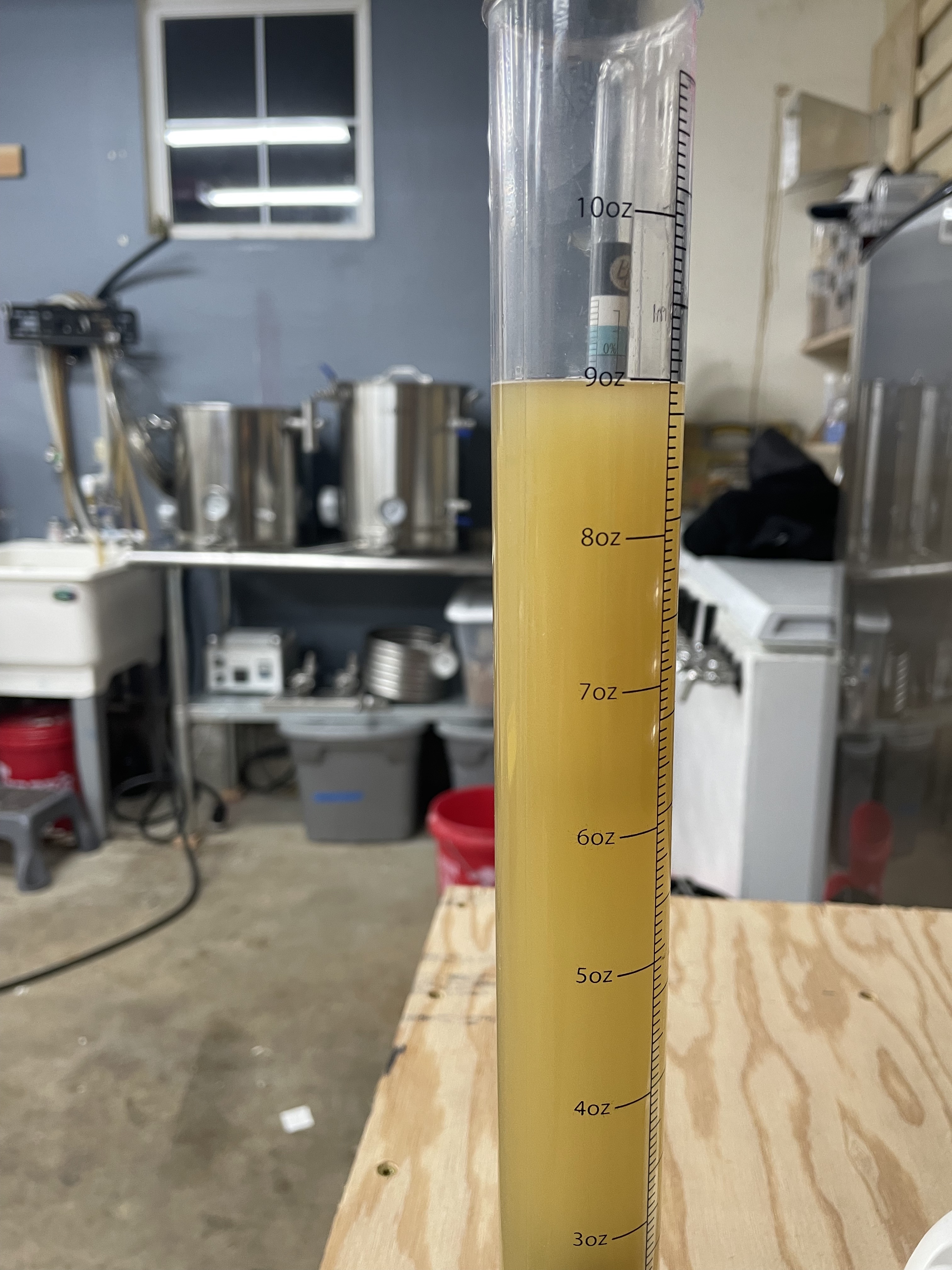

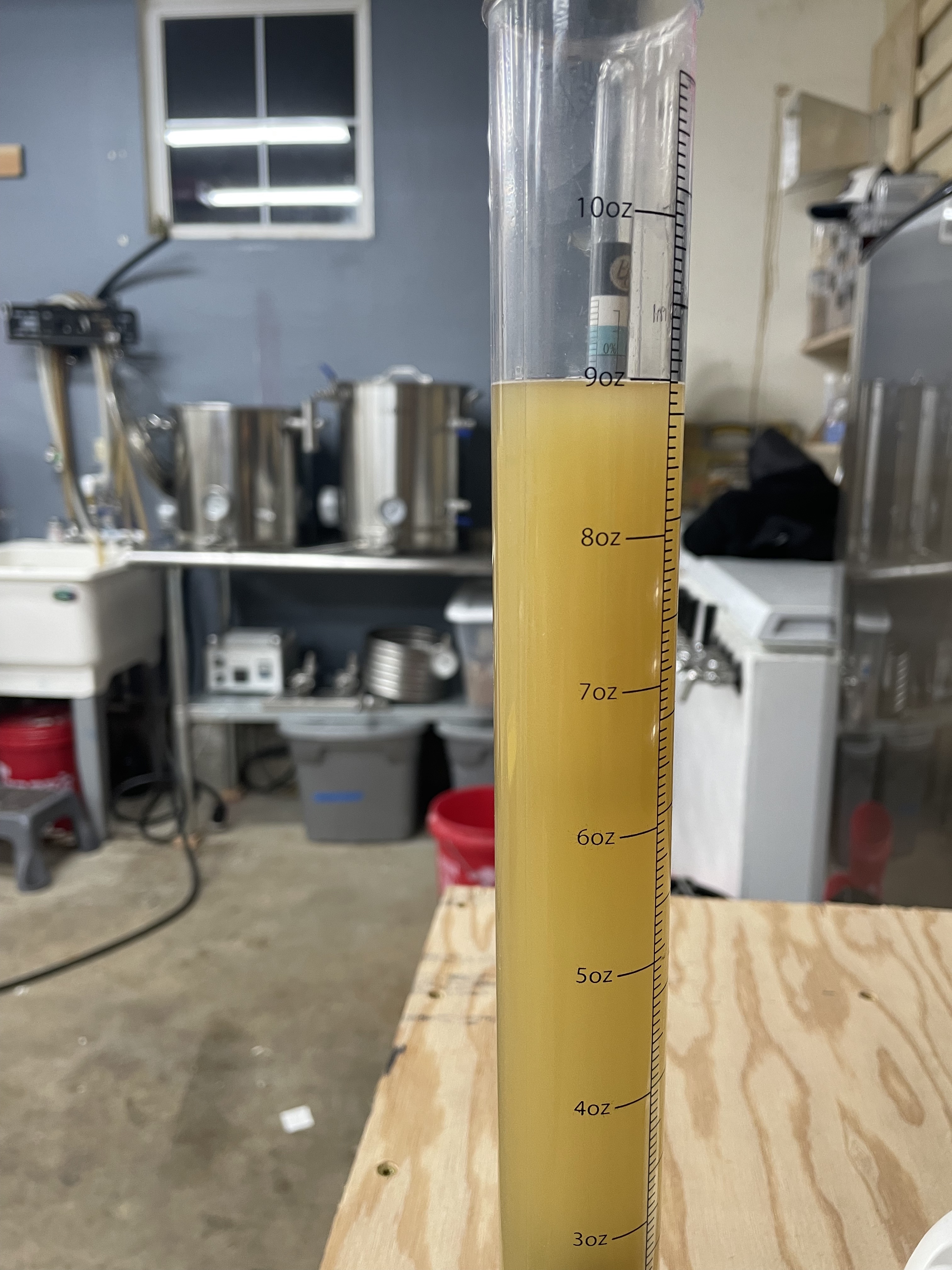

At flameout, I shut off the PID controlling the 5500w BK element and turned on the cold water. After chilling the wort down to 65F via counterflow chiller and constant recirculating back into the BK, I pumped it to my fermenter and took a refractometer sample:

I then moved my fermenter over to my glycol station, placed the heatwrap around it and set the inkbird controller to 65F. Since the garage is in the 40s, I don't expect the pump moving the glycol to kick on--I believe ambient temp is cool enough to keep the actual beer/wort temp around where I need it with just the heating element kicking on for stability and ramping.

I then added the full 1.5L starter at high krausen and got to every brewer's favorite task: CLEANING.

All clean and (mostly) put away!

Summary:

It was a solid brew day. I missed my target gravity by about 2 points. I must've boiled off slightly less than I thought, or had a volume problem. Who knows? Good enough.

My preboil OG was 1.049 before adding the dextrose. I subbed my 15 minute styrian golding addition for 1/2 oz EKG. It's all I had, and is likely similar enough for a 15 minute addition.

I also forgot whirlfloc, but plan to use gelatin and a nice cold nap to get that gorgeously clear Affligem presentation. I'm excited for this one!

Moving forward, I'll begin ramping 1F per day once I'm seeing signs of active fermentation until I reach 75F. I will then hold the temperature until reaching FG, wait a few days, and then bring it down to 50F for 2 weeks before crashing, fining, and kegging.

I'll be updating as fermentation progresses, and will source a bottle of Affligem for a side-by-side comparison once it's ready.

So please pardon this short recap.

It was a good brew day. Here were my stats

OG: 1.062 (target 1.064)

Water chemistry: Yellow balanced

Ca: 55

Mg: 4.8

Na: 22

Cl: 65

SO4: 75

Mash ph: 5.4 (used 4ml lactic acid).

Doughed in at 3:00pm to hit a strike temperature of 150F. I then recirculated through my HERMS coil, which sits in a PID-controlled hot liquor with a 5500w element. I do full-volume mashes, I don't sparge (I can't justify the extra involvement for 5-10% more efficiency), and I often recirculate the mash for hours. Today my total mash time was 4 hours for an efficiency of about 75%. For me, it's a set-it-and-get-to-it-when-you-can process. No temperature drop, no pH change--just crystal clear wort after what is essentially a perpetual vorlauf.

This atypical process was borne out of necessity--if I was still using an igloo cooler and natural gas, I'd need to be way more hands-on with the process, which is hard to find time for, and would result in me getting to brew far less often.

[

[

Anyway, after mashing, I took a preboil gravity reading and hit 1.049. This is BEFORE adding the dextrose.

I pumped the wort over to the BK and used a hop spider to catch any chunks of grain that didn't settle into the grain bed/got pushed over through the pump. I then brought it up to a boil, added my 60 minute addition of Mittelfruh, and promptly cleaned my MLT out. The Mittelfruh looked awesome--so bright!

I then lidded the kettle, turned on the steam condenser, and proceeded with a pretty business-as-usual boil--adding Spalt at 30, and EKG at 15 (I thought I had a big bag of Styrian but couldn't find it, so I was forced to substitute! Should be OK, though). I also added the 1 LB bag of dextrose at about 15 minutes, some yeast nutrient, and began recirculating the boiling wort through my pumps, counterflow chiller and hoses to sanitize everything. What a mess of hoses it is! But it works. Also, as an aside, the DIY steam condenser is 1000% worth it and is my favorite piece of equipment--I can brew without fogging up the garage or having to roll the doors up.

At flameout, I shut off the PID controlling the 5500w BK element and turned on the cold water. After chilling the wort down to 65F via counterflow chiller and constant recirculating back into the BK, I pumped it to my fermenter and took a refractometer sample:

I then moved my fermenter over to my glycol station, placed the heatwrap around it and set the inkbird controller to 65F. Since the garage is in the 40s, I don't expect the pump moving the glycol to kick on--I believe ambient temp is cool enough to keep the actual beer/wort temp around where I need it with just the heating element kicking on for stability and ramping.

I then added the full 1.5L starter at high krausen and got to every brewer's favorite task: CLEANING.

All clean and (mostly) put away!

Summary:

It was a solid brew day. I missed my target gravity by about 2 points. I must've boiled off slightly less than I thought, or had a volume problem. Who knows? Good enough.

My preboil OG was 1.049 before adding the dextrose. I subbed my 15 minute styrian golding addition for 1/2 oz EKG. It's all I had, and is likely similar enough for a 15 minute addition.

I also forgot whirlfloc, but plan to use gelatin and a nice cold nap to get that gorgeously clear Affligem presentation. I'm excited for this one!

Moving forward, I'll begin ramping 1F per day once I'm seeing signs of active fermentation until I reach 75F. I will then hold the temperature until reaching FG, wait a few days, and then bring it down to 50F for 2 weeks before crashing, fining, and kegging.

I'll be updating as fermentation progresses, and will source a bottle of Affligem for a side-by-side comparison once it's ready.

Last edited:

luckybeagle

Making sales and brewing ales.

Well F....

I just looked back at my post and realized I did NOT add gypsum when measuring out my brewing salts. I was distracted, and therefore the batch got none.

It's now in my fermenter about 10 hours post-pitch. Can I boil and cool some water, add gypsum, and pour it into the fermenter? I know it helps with mashing, but I can't turn back time unfortunately.

Add it, or leave it be??

With this mistake, my water chemistry looked like this:

Ca: 25

Mg: 5

NA: 22

Cl: 64

SO4: 3

Mash pH: 5.48

That really threw off the Ca and SO4. I used to brew without any additions--just plain tap water--and produced tasty beers, but this is kind of not sitting well with me given the care that went into everything else!!

Should I add the gypsum to the fermenter or leave it be??

I just looked back at my post and realized I did NOT add gypsum when measuring out my brewing salts. I was distracted, and therefore the batch got none.

It's now in my fermenter about 10 hours post-pitch. Can I boil and cool some water, add gypsum, and pour it into the fermenter? I know it helps with mashing, but I can't turn back time unfortunately.

Add it, or leave it be??

With this mistake, my water chemistry looked like this:

Ca: 25

Mg: 5

NA: 22

Cl: 64

SO4: 3

Mash pH: 5.48

That really threw off the Ca and SO4. I used to brew without any additions--just plain tap water--and produced tasty beers, but this is kind of not sitting well with me given the care that went into everything else!!

Should I add the gypsum to the fermenter or leave it be??

Thanks for the great details. Skip the gypsum and get 'em next time. What F.G. are you looking for? I would be hoping for 1.006 - 1.008 Looking forward to the fermentation and the finished product notes.

luckybeagle

Making sales and brewing ales.

Quick update--I brewed this one 7 days ago and just took my first gravity reading/taste test. My hydrometer says 1.010, but it reads about 3 points low--so 1.013ish. It's very opaque/milky. I'm thinking/hoping it'll chew through another 5-7 points before its done. Pineapple and sweet fruit on the nose, slightly too sweet with some fruity/bubble gum qualities on the taste. To be expected, though--it really needs to attenuate further.

Love the color, though. It's now at 74F and will be held there until it reaches FG. I'll check again in another week.

FYI after a lot of mental back-and-forth, I ended up adding the gypsum in boiled/cooled water. My thinking was the improved calcium levels will help yeast health, especially since our tap water has next to none. Adding them 8 or so hours after the pitch isn't ideal, but unlikely to be detrimental. I just couldn't leave it be. Next time I won't forget, and this'll simply be a non-issue

Love the color, though. It's now at 74F and will be held there until it reaches FG. I'll check again in another week.

FYI after a lot of mental back-and-forth, I ended up adding the gypsum in boiled/cooled water. My thinking was the improved calcium levels will help yeast health, especially since our tap water has next to none. Adding them 8 or so hours after the pitch isn't ideal, but unlikely to be detrimental. I just couldn't leave it be. Next time I won't forget, and this'll simply be a non-issue

luckybeagle

Making sales and brewing ales.

Update: I kegged this beer on 3/1, so it's been in the keg for a little over 3 weeks. It was brewed 37 days ago.

This yeast is so stubbornly cloudy and non-flocculant!

I'm probably going to just stay out of it for another week or two and assess again. I really don't want to add gelatin at this point, but I'm also doubtful it'll ever get all that bright without it. Still, it's proving to be a well-balanced and tasty drinker. I haven't done a side-by-side with an Affligem yet, but it does taste similar based on memory. Dry and well-attenuated, fruity and with a gentle honey-like sweetness. hops are in perfect balance and are pungent but not overwhelming. Foam lingers well and laces a bit.

The beer is still a bit "green," according to my wife, so hopefully with time I get both the clarity and maturity that the beer calls for. Overall I'm impressed and would brew this again--although I might opt for bottle conditioning instead. The foam would probably be more dense and lacy if I did. Maybe?

This yeast is so stubbornly cloudy and non-flocculant!

I'm probably going to just stay out of it for another week or two and assess again. I really don't want to add gelatin at this point, but I'm also doubtful it'll ever get all that bright without it. Still, it's proving to be a well-balanced and tasty drinker. I haven't done a side-by-side with an Affligem yet, but it does taste similar based on memory. Dry and well-attenuated, fruity and with a gentle honey-like sweetness. hops are in perfect balance and are pungent but not overwhelming. Foam lingers well and laces a bit.

The beer is still a bit "green," according to my wife, so hopefully with time I get both the clarity and maturity that the beer calls for. Overall I'm impressed and would brew this again--although I might opt for bottle conditioning instead. The foam would probably be more dense and lacy if I did. Maybe?

Thanks for the update. That is very cloudy. Did the beer look this cloudy when you kegged it? I would check your process from boil kettle to fermenter and then finished beer to keg. Also, did you use any kettle finings like Whirlfloc? Calcium plays a part in wort clarity, so definitely get your calcium up to 50-100 ppm next time.

luckybeagle

Making sales and brewing ales.

Yeah, it is pretty cloudy. I did use whirlfloc but I had an issue with my brewing salts (forgot to add them to the mash--ended up boiling and cooling a little water with them in it and adding it a few hours after yeast pitch. Not ideal at all. I think I am going to just hit it with gelatin and leave it alone until the weekend, draw off whatever I can, and see if that helps.Thanks for the update. That is very cloudy. Did the beer look this cloudy when you kegged it? I would check your process from boil kettle to fermenter and then finished beer to keg. Also, did you use any kettle finings like Whirlfloc? Calcium plays a part in wort clarity, so definitely get your calcium up to 50-100 ppm next time.

Taste is pretty good, but presentation is lacking, for sure.

Thanks for the info about calcium--I didn't know that. Might need to finally crack the spine on my "Water" book by Palmer, lol.

Similar threads

- Replies

- 4

- Views

- 437

- Replies

- 3

- Views

- 680