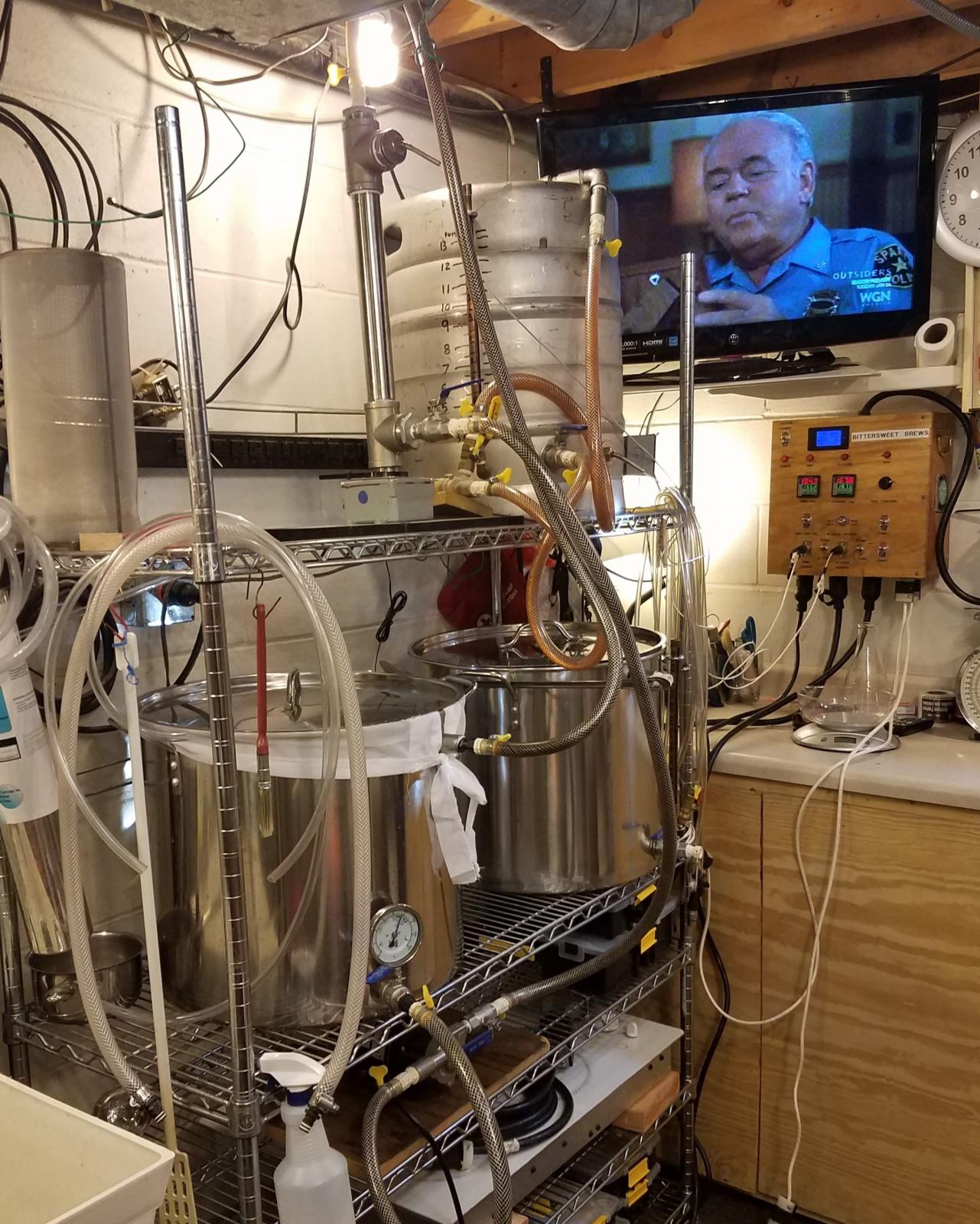

BitterSweetBrews

Tim Trabold

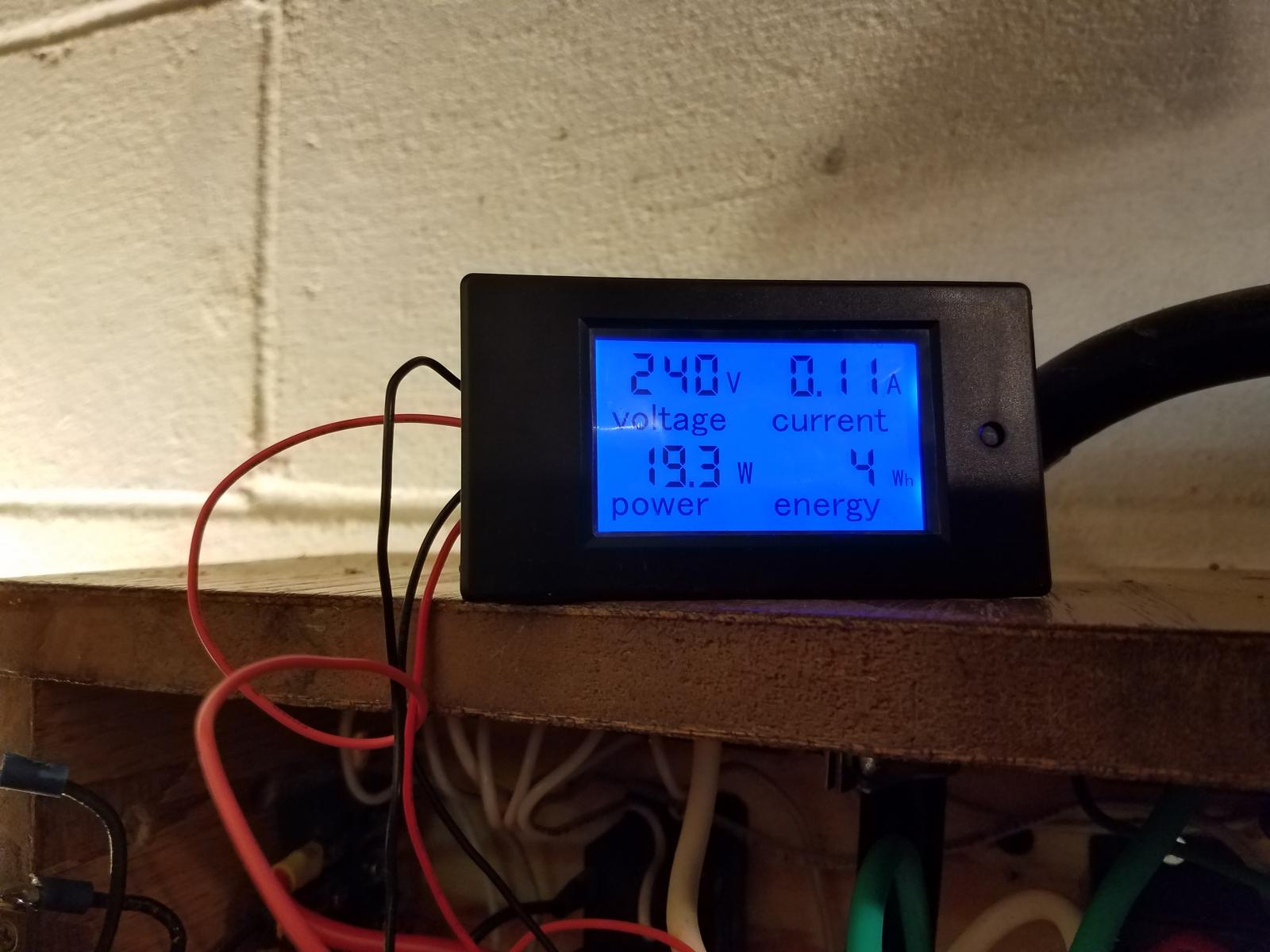

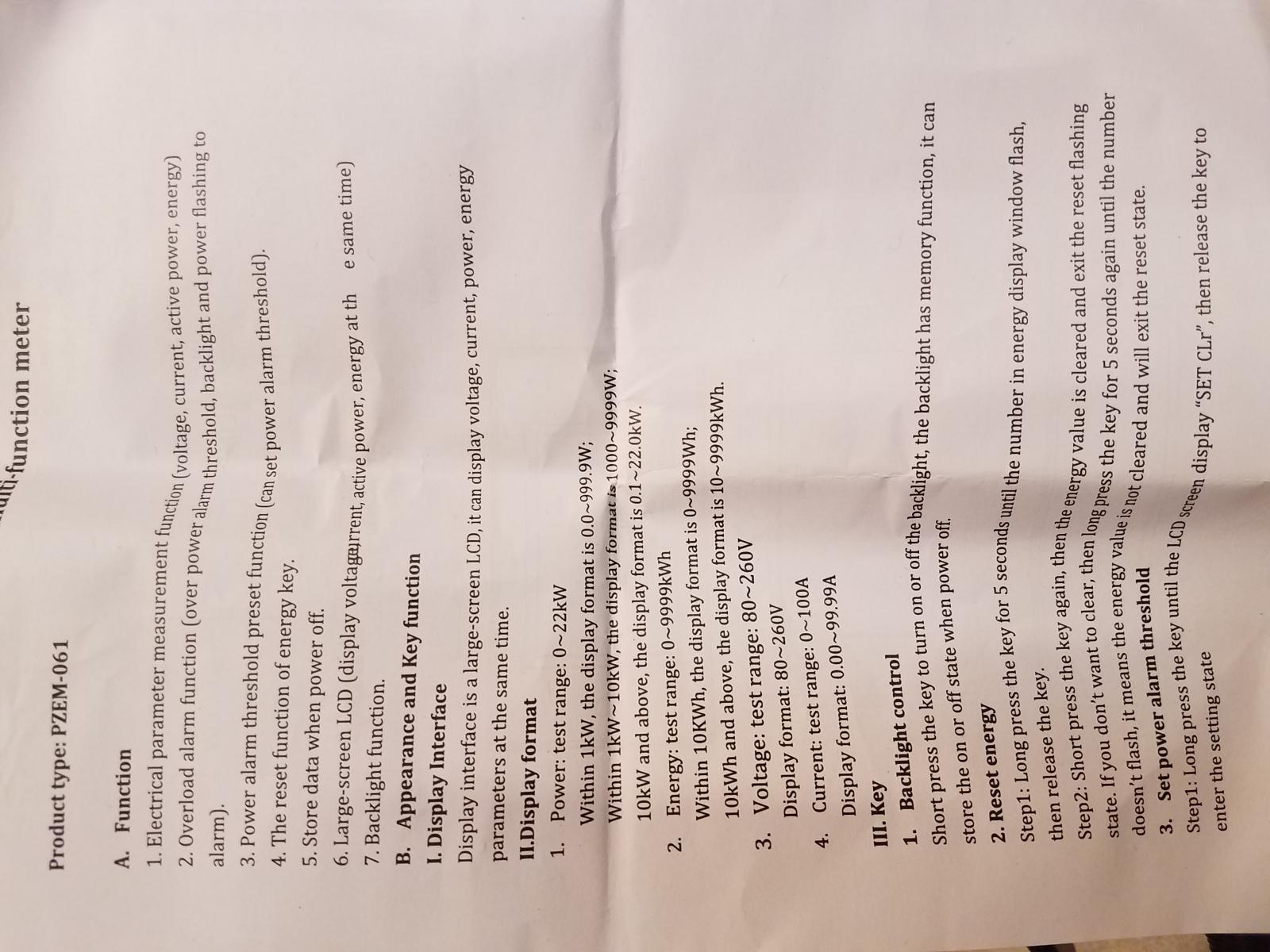

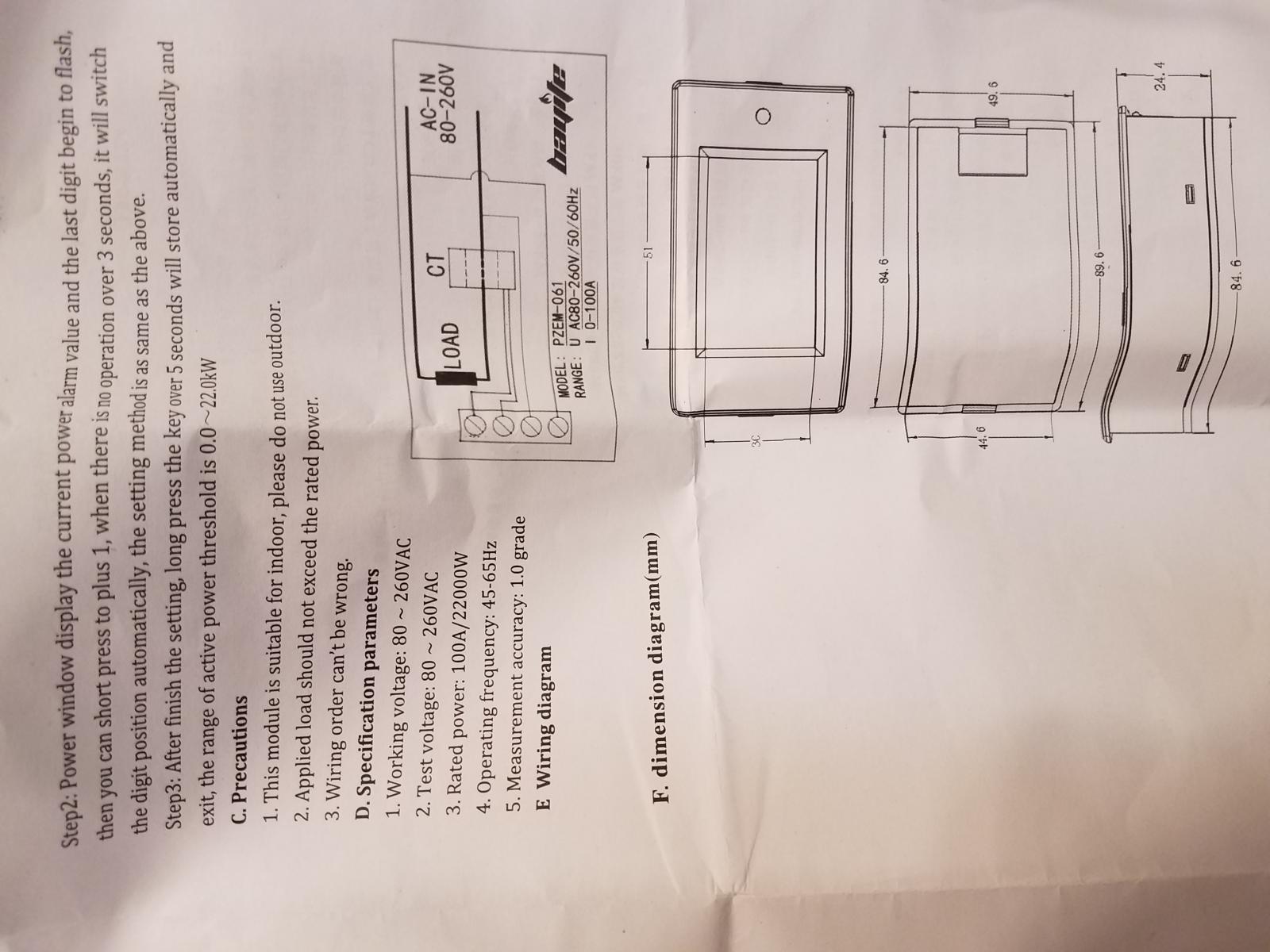

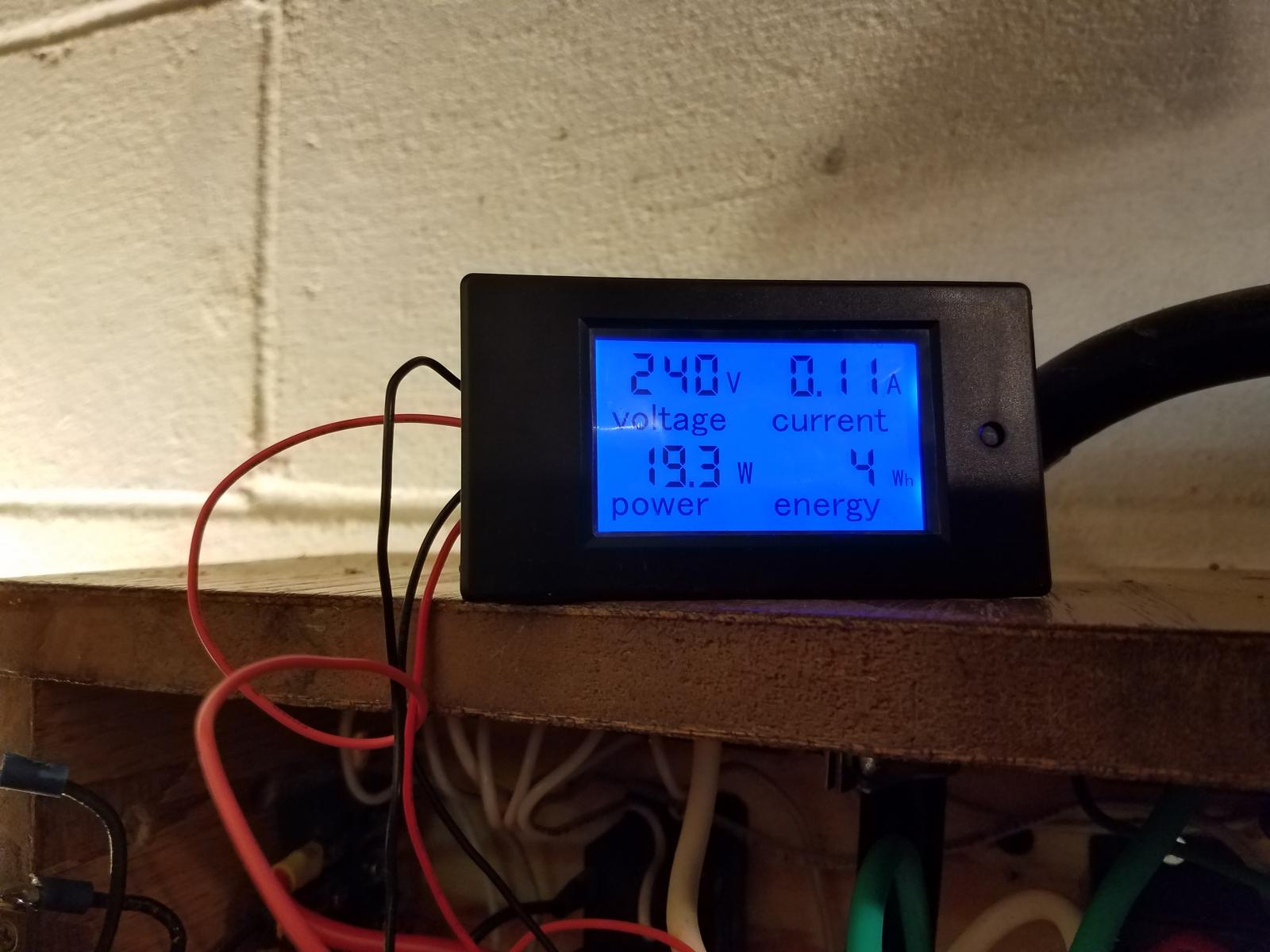

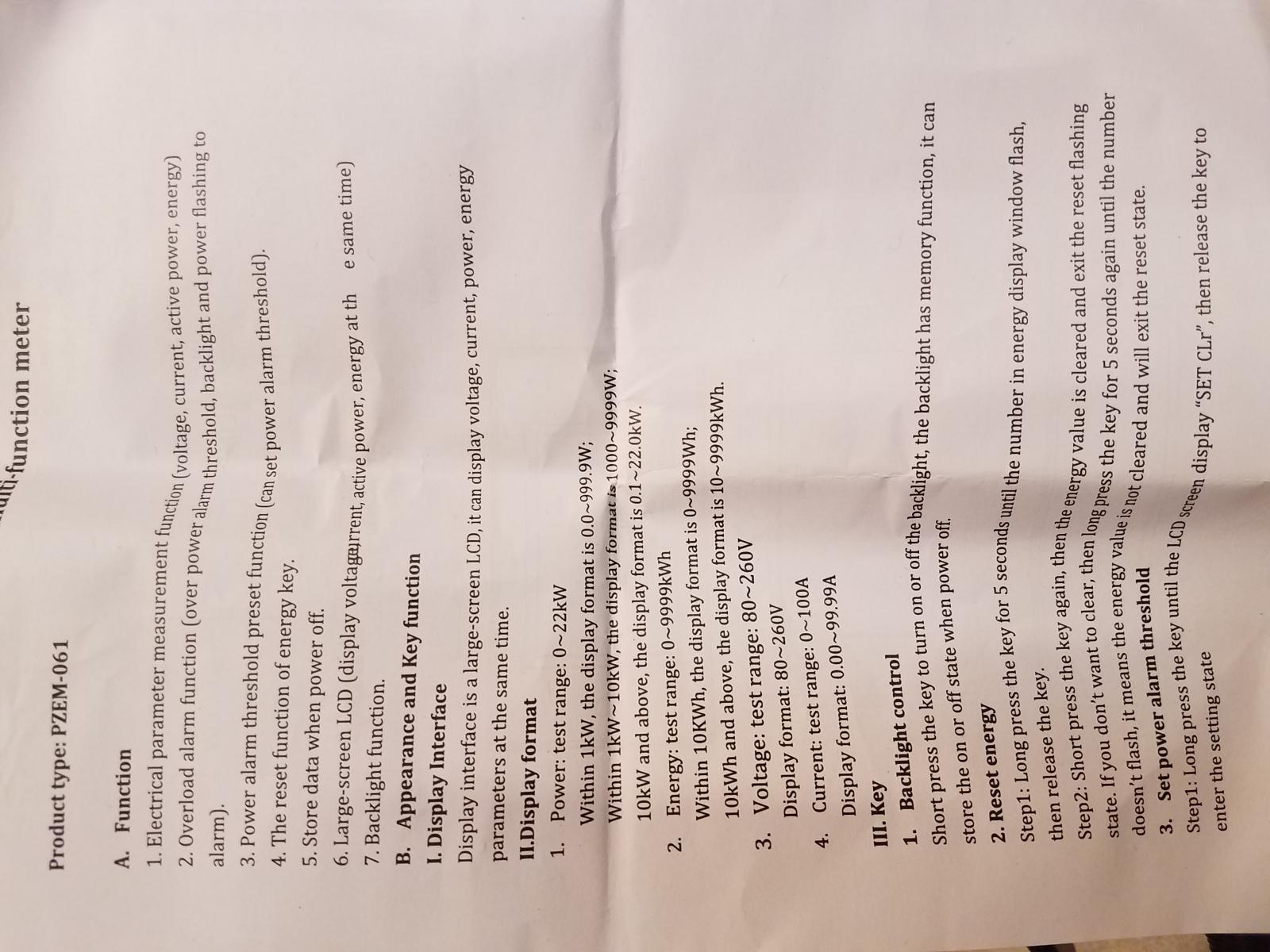

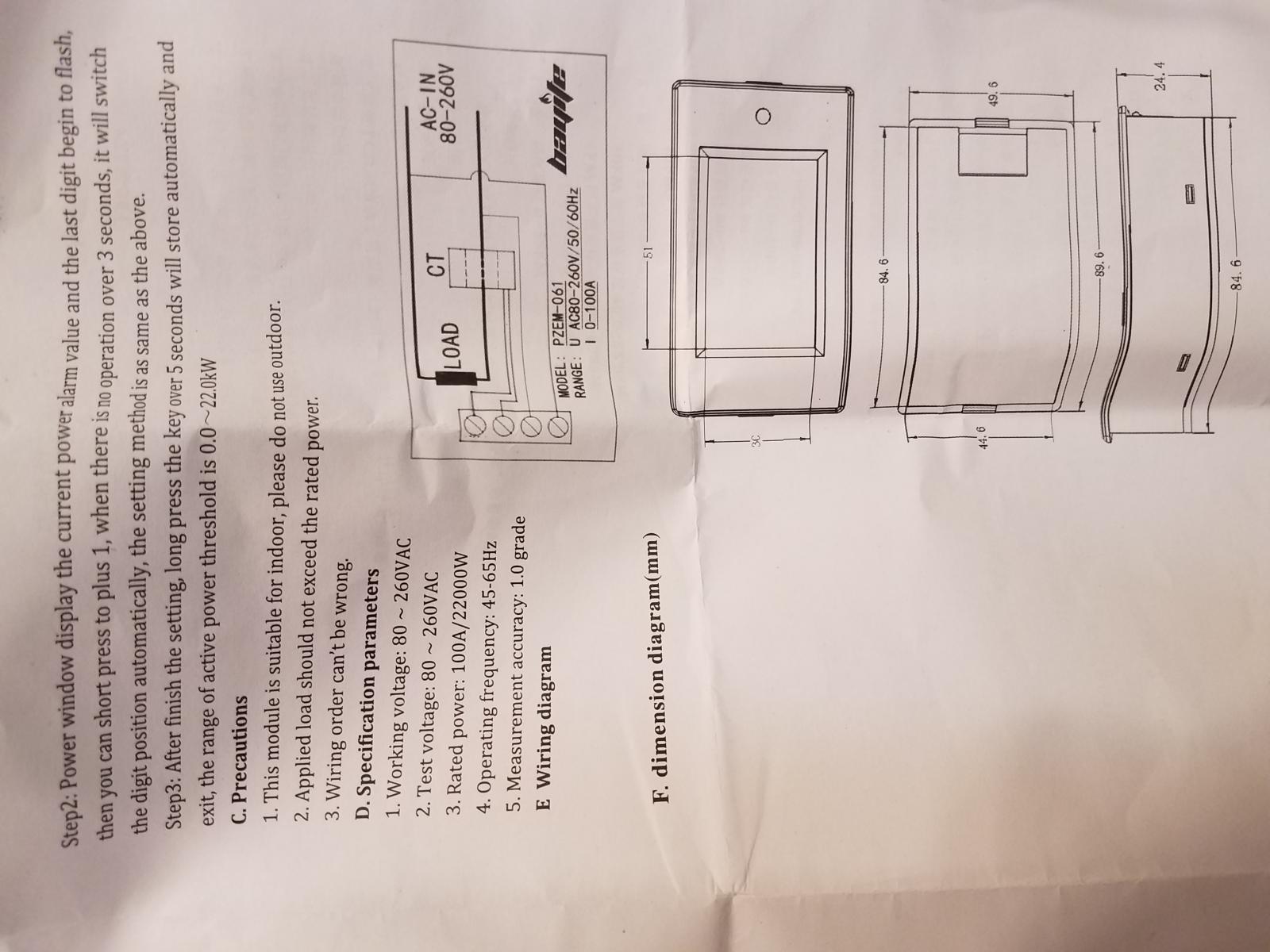

I just bought an Amp/Volt meter for my panel. I am trying to figure out how I need to wire it in. I have wired it a few ways and none seem to work totally right.

In addition to the overall panel 240v circuit, I have separate 120v circuits on each phase for pumps and 120v RIMS. I have the pump outlets on one side and the RIMS outlet on the other. That is, I have two circuits that use one hot and the neutral to form a 120v circuit. I have separate circuits using both hots.

The problem is measuring total amperage draw for both 120v and 240v devices. I am uploading pictures of the device and its directions/schematic.

1. If I run a hot load wire through the coil it will measure 240 amperage right, but will only give me amperage for 120v on the side this hot is on. If I plug in 120v to the other side's circuit it doesn't measure it.

2. If I run both hot's through the coil it measures 120v on each side but doesn't measure 240.

3. If I run one hot and the neutral through the coil it measures differences, but it doubles up the amperage on the 120v size that the hot is from. So, it is inaccurate.

4. If I run just the Neutral through, it measures 120v loads on both circuits, but not anything 240v.

I want to get the full load for the panel for any devices running at any time. At this point, I can only figure out that I would need to re-wire all 120v to one side or the other and use that line for the measurement. I would rather not do that unless there is no other way.

Any advice would be greatly appreciated.

Thanks

Tim Trabold

In addition to the overall panel 240v circuit, I have separate 120v circuits on each phase for pumps and 120v RIMS. I have the pump outlets on one side and the RIMS outlet on the other. That is, I have two circuits that use one hot and the neutral to form a 120v circuit. I have separate circuits using both hots.

The problem is measuring total amperage draw for both 120v and 240v devices. I am uploading pictures of the device and its directions/schematic.

1. If I run a hot load wire through the coil it will measure 240 amperage right, but will only give me amperage for 120v on the side this hot is on. If I plug in 120v to the other side's circuit it doesn't measure it.

2. If I run both hot's through the coil it measures 120v on each side but doesn't measure 240.

3. If I run one hot and the neutral through the coil it measures differences, but it doubles up the amperage on the 120v size that the hot is from. So, it is inaccurate.

4. If I run just the Neutral through, it measures 120v loads on both circuits, but not anything 240v.

I want to get the full load for the panel for any devices running at any time. At this point, I can only figure out that I would need to re-wire all 120v to one side or the other and use that line for the measurement. I would rather not do that unless there is no other way.

Any advice would be greatly appreciated.

Thanks

Tim Trabold