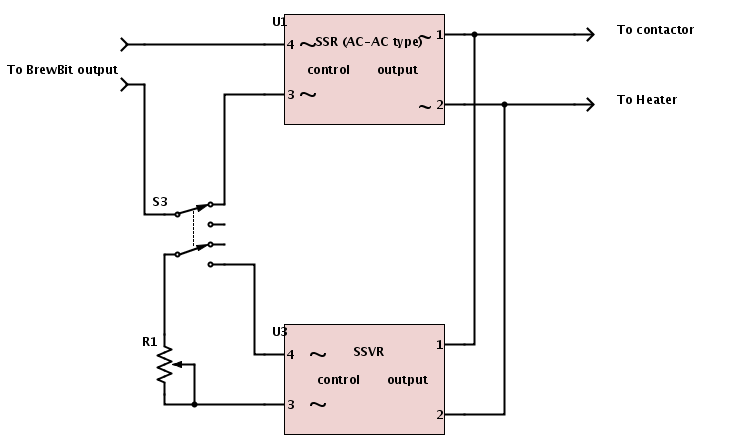

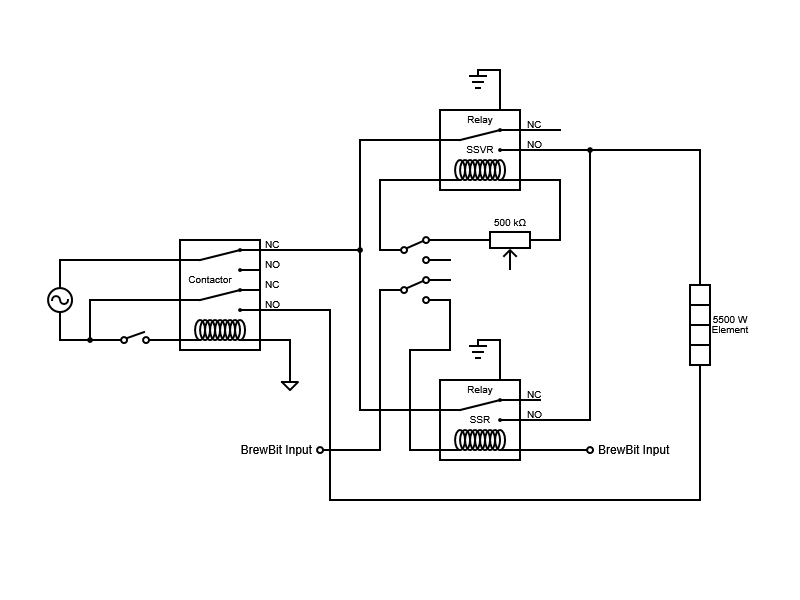

I just got a Hot Rod heat stick and I'm going to build a controller to run it. Here is my plan for wiring it so far using a BrewBit controller to run one SSR for use in the HLT and using an SSVR to control when boiling. I'm wondering here about the switching of the leg to feed one or the other SSR. I ordered a 120v 3 position switch and then I realized it's only rated for 10 amps. Does anyone have a better idea how to handle switching this?

View attachment 1416533998710.jpg

View attachment 1416533998710.jpg