Gameface

Well-Known Member

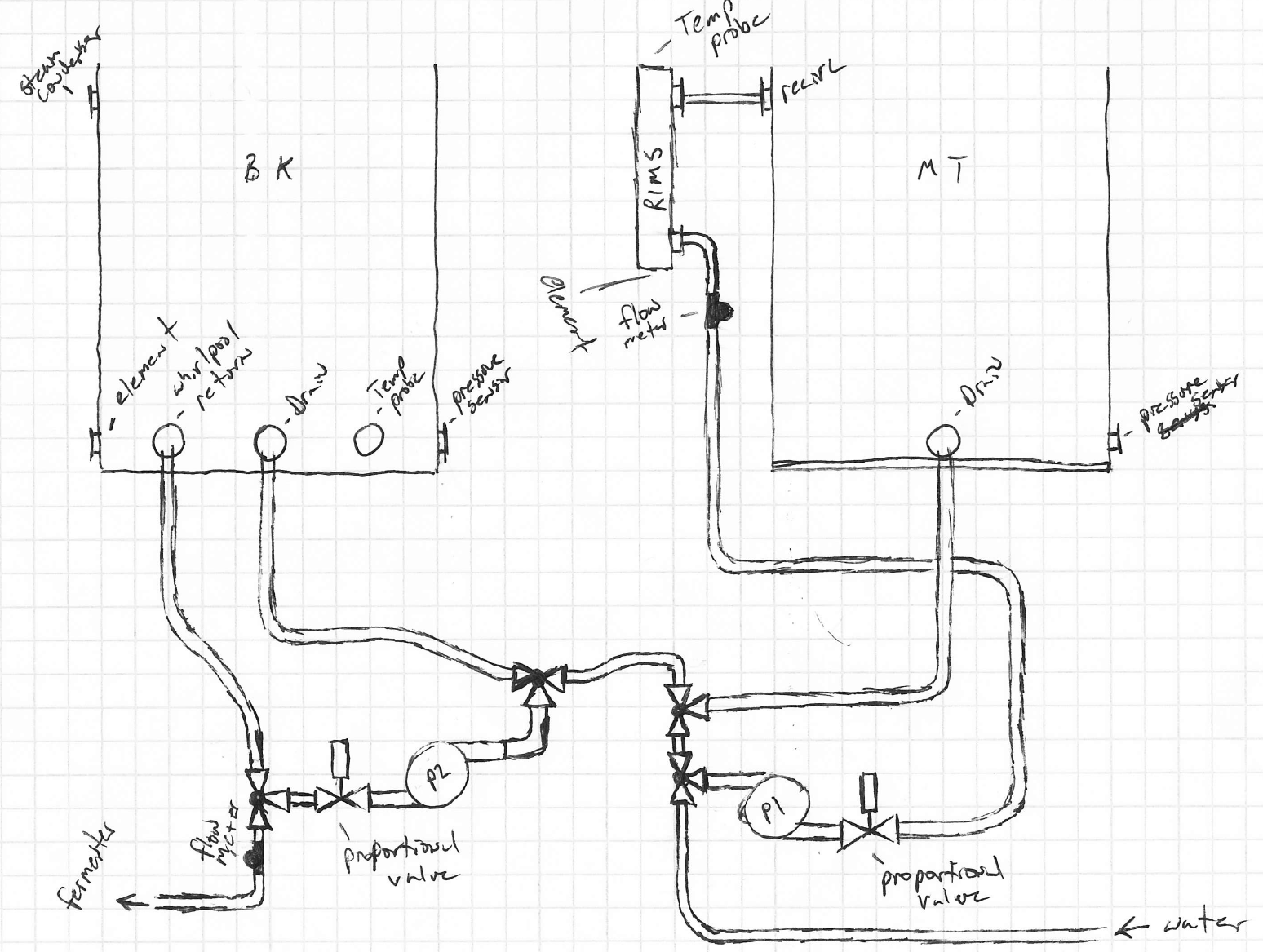

I'm very excited to get started building a new home brewery. I've been brewing 10 gal batches on an eHERMS system I built a few years ago. I'm selling that and starting fresh on a 15 gal batch 2 vessel RIMS system.

I should start buying stuff this week. I want to throw my ideas out there and hope some of you out there are willing to help me catch stuff that I might have missed.

Along with the new kettles and BruControl based automation I'm also buying 2 Spike Brewing CF15 unitanks and a glycol chiller.

And if all that isn't enough to take on I'm going to give LODO a shot.

Wish me luck!

I'll post more details soon.

I should start buying stuff this week. I want to throw my ideas out there and hope some of you out there are willing to help me catch stuff that I might have missed.

Along with the new kettles and BruControl based automation I'm also buying 2 Spike Brewing CF15 unitanks and a glycol chiller.

And if all that isn't enough to take on I'm going to give LODO a shot.

Wish me luck!

I'll post more details soon.