I constructed a manifold out of pvc and barb fittings for all the tubing, and I don't like it.

I think it leaks, but I'm not too excited about reconstructing a new one... So I'm here looking for what other people use (with good results).

In retrospect I wish I would have ordered compression fittings for my stainless check ball valves instead of barbies.

Should I scrap the whole thing and start over, or is it worth attempting to fix?

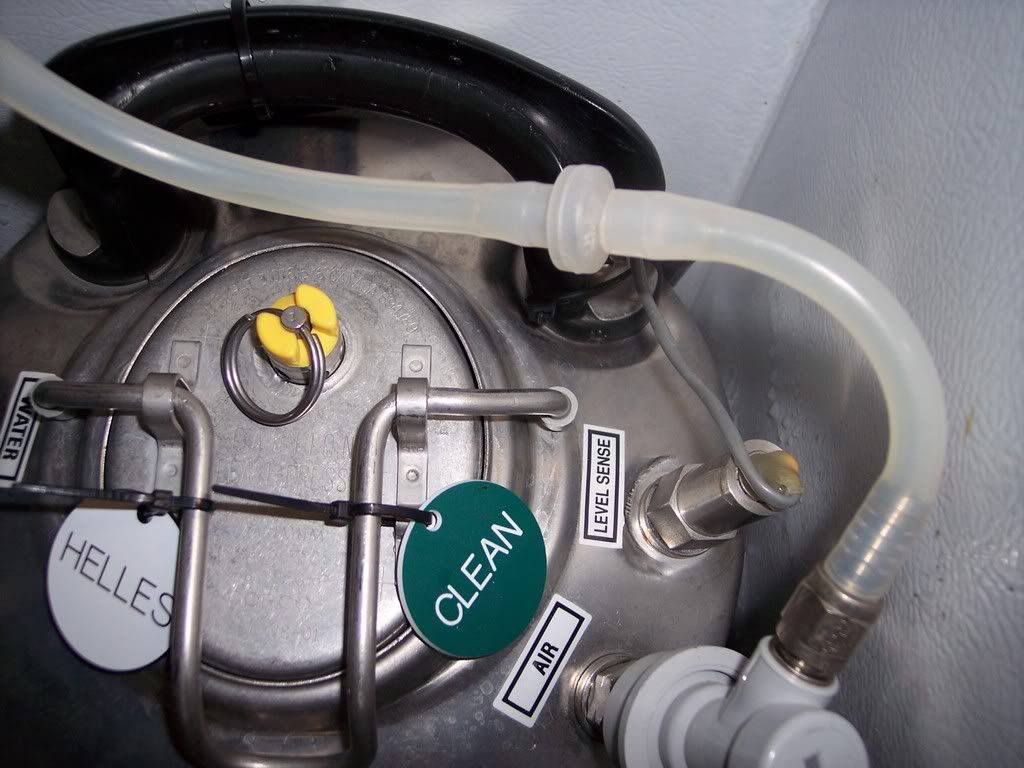

You can see a picture of the manifold in the back... only picture I have of it at work...

I think it leaks, but I'm not too excited about reconstructing a new one... So I'm here looking for what other people use (with good results).

In retrospect I wish I would have ordered compression fittings for my stainless check ball valves instead of barbies.

Should I scrap the whole thing and start over, or is it worth attempting to fix?

You can see a picture of the manifold in the back... only picture I have of it at work...