I'm in the process of designing a 4 keg Keezer. The CO2 tank and regulator that I use to pour from will be connected to a 4-way manifold.

However I also want to be able to use this same CO2 tank outside the Keezer for various tasks such as pressure fermenting or pressure transferring beer. Since I am still in the planning stage of this project, I'd like to eliminate the potential headache of struggling to disconnect the CO2 tank/regulator from the manifold each and every time I want to move it to use it somewhere else in my brewery.

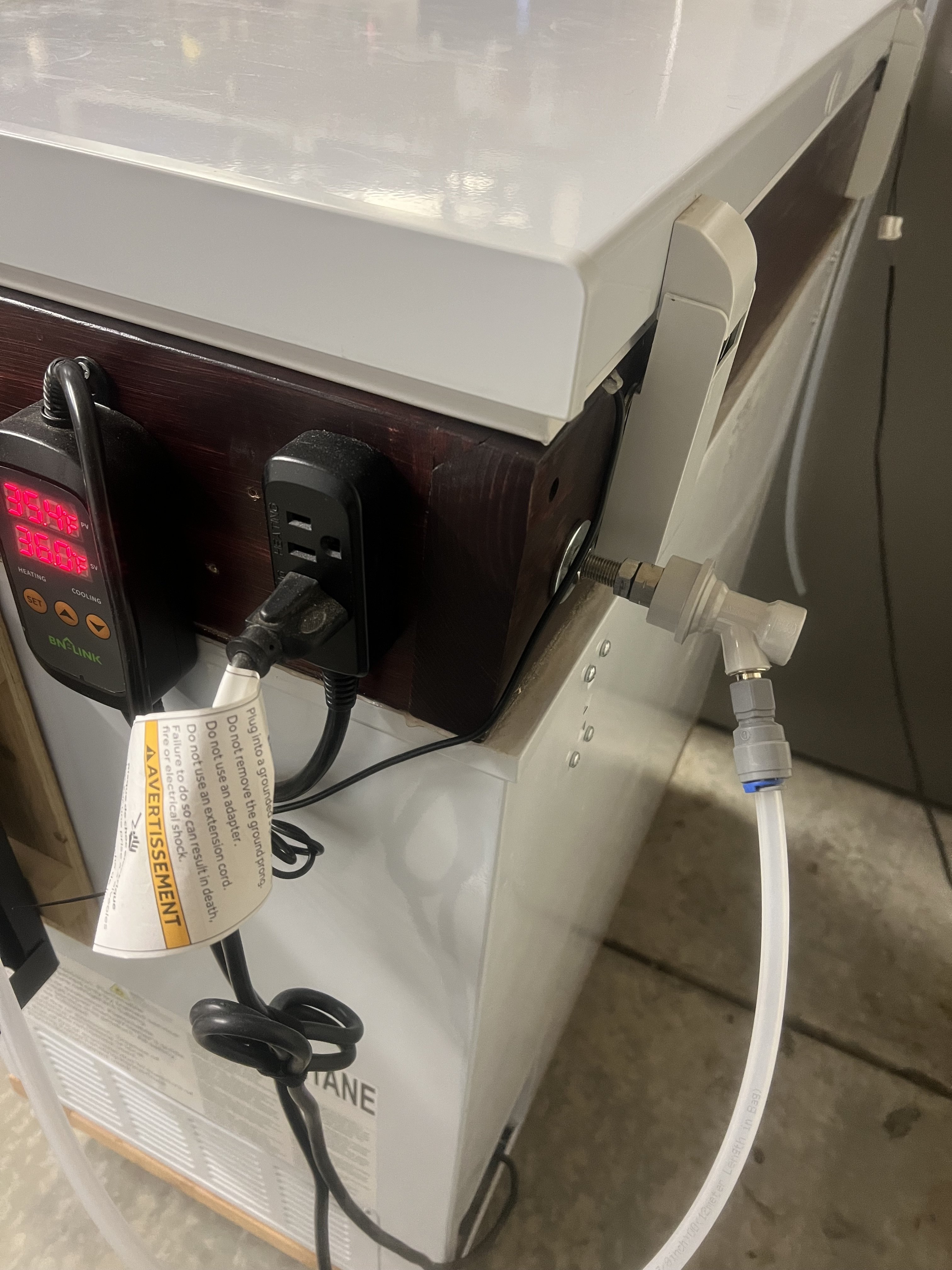

I'm leaning towards keeping the CO2 tank outside the keezer in order to maximize the space inside for beer, and also to make the tank easier to maneuver.

My question: What is the most convenient way to accomplish connecting and disconnecting the CO2 tank from the gas distribution manifold? Ideally, I'd like something that I could mount to the exterior of the keezer, like a corny keg ball lock fitting.

However I also want to be able to use this same CO2 tank outside the Keezer for various tasks such as pressure fermenting or pressure transferring beer. Since I am still in the planning stage of this project, I'd like to eliminate the potential headache of struggling to disconnect the CO2 tank/regulator from the manifold each and every time I want to move it to use it somewhere else in my brewery.

I'm leaning towards keeping the CO2 tank outside the keezer in order to maximize the space inside for beer, and also to make the tank easier to maneuver.

My question: What is the most convenient way to accomplish connecting and disconnecting the CO2 tank from the gas distribution manifold? Ideally, I'd like something that I could mount to the exterior of the keezer, like a corny keg ball lock fitting.