That is the coolest thing I've ever seen JohnnyMac. Good work, man!

Thanks! I am brewing a nut brown ale today on the system - my 10th batch on the system now.

That is the coolest thing I've ever seen JohnnyMac. Good work, man!

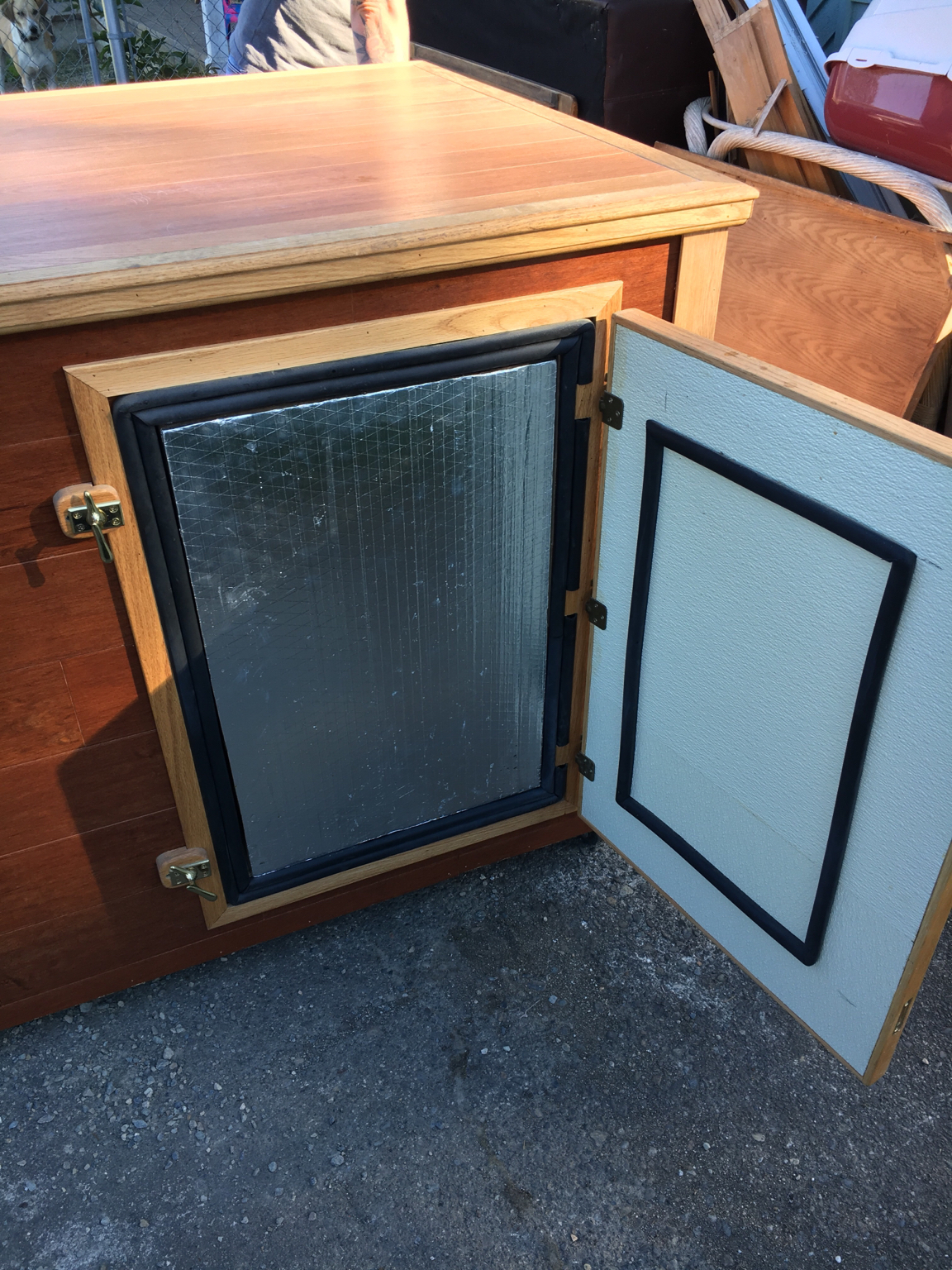

here's some pictures of my fermentation chamber I built. My intent was to make it look like a shipping create. Some fool was throwing away a perfectly good tiny office fridge. To small to fit anything... or was it. When I use it to lager it does take about a day to get it down to temp but I do believe that this is a good thing in that I'm not shocking the yeast with a quick temp change. I like to start my lagers fermenting around 60 and slow lower the temp down towards 50 degrees f. I use a stc-1000 for temp control and wired an outlet inside the chamber so I can plug in a carboy heater if I desire a warmer fermentation. I can fit 2- 6 gallon carboys in here. Also not pictured, I later added twist locks that clamp the door on at all 4 corners but also enable complete removal. sorry about the sideways pics. I can't seem to figure out how to rotate them on this site.

Hey Ampsman

What kind of Mini Fridge is that ?

That holds your Conical so nicely ?

Thanks

S

here's some pictures of my fermentation chamber I built. My intent was to make it look like a shipping create. Some fool was throwing away a perfectly good tiny office fridge. To small to fit anything... or was it. When I use it to lager it does take about a day to get it down to temp but I do believe that this is a good thing in that I'm not shocking the yeast with a quick temp change. I like to start my lagers fermenting around 60 and slow lower the temp down towards 50 degrees f. I use a stc-1000 for temp control and wired an outlet inside the chamber so I can plug in a carboy heater if I desire a warmer fermentation. I can fit 2- 6 gallon carboys in here. Also not pictured, I later added twist locks that clamp the door on at all 4 corners but also enable complete removal. sorry about the sideways pics. I can't seem to figure out how to rotate them on this site.

Yes, that is my issue. I have been trying to find the best placement of my temp probe to maintain beer temp without much fluctuation. Lately with the temps in the 10's and 20's my heater has raised ambient way above ferm temp to get a 1 or 2 deg. rise in beer temp.A question for those more knowledgeable would be whether or not it is better to have the sensor in the liquid or the air - in would have the ac booming when it's out of range for a while (like you describe) the other would have it cycling on and off more often....

Yes, that is my issue. I have been trying to find the best placement of my temp probe to maintain beer temp without much fluctuation. Lately with the temps in the 10's and 20's my heater has raised ambient way above ferm temp to get a 1 or 2 deg. rise in beer temp.

I'm thinking about placing some 5-gal. buckets of water in there with some aquarium heaters to increase thermal mass and slow the ambient fluctuations. At least during the winter.

Some pretty sick designs in this thread.

I'm currently using a chest freezer that's being controlled with an inkbird, but I lost the use of the freezer storage (for other items) so I'm thinking about building a dedicated ferm chamber.

I see many on here that use the guts of either a mini-fridge, a window ac unit, or a freezer. Can someone share the pros and cons of using each as the cooling system?

Enter your email address to join: