You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brew rig ideas

- Thread starter Layne

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Pierce

Well-Known Member

If you make this up like you did your backyard brewpub I will be jealous yet again.

As for ideas. Build it at my house. No?

As for ideas. Build it at my house. No?

Sawdustguy

Well-Known Member

Question, during the fill cycle, why do you have the BK feeding the MLT and the HLT? Wouldn't you just fill the HLT with cold water to heat the strike and sparge water and feed that to the MLT?

Is this what you are trying to do?

Is this what you are trying to do?

That is an option.

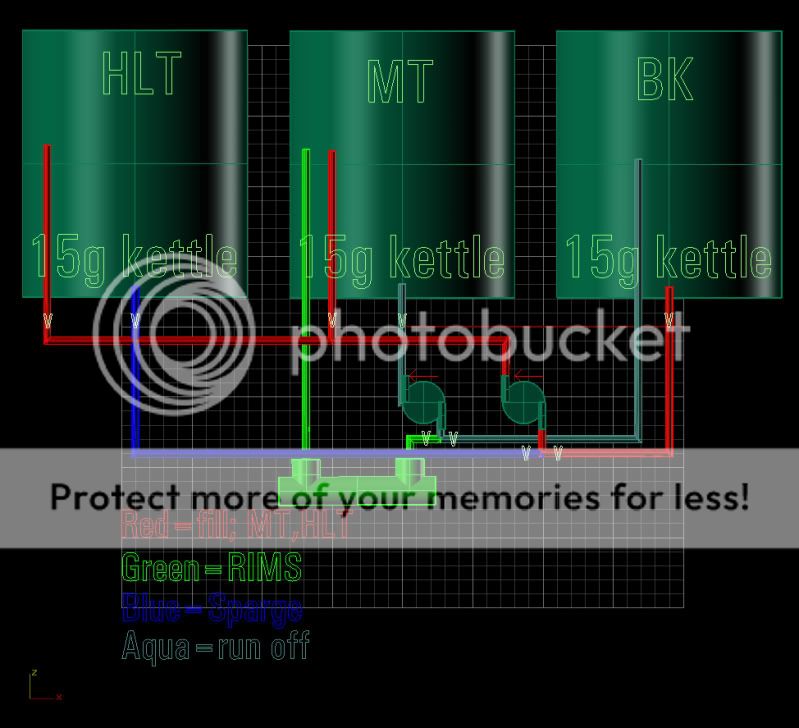

In my drawing, the MLT wouldn't need a heat source. Heat in the BK, and store in the HLT. That may not be viable, but is the thought process for the moment. Heat water in the BK-send to MT, Recirq RIMS, Heat water in BK and send to HLT to hold for sparge. Three kettles, one Burner, one RIMS heater.

Thoughts?

In my drawing, the MLT wouldn't need a heat source. Heat in the BK, and store in the HLT. That may not be viable, but is the thought process for the moment. Heat water in the BK-send to MT, Recirq RIMS, Heat water in BK and send to HLT to hold for sparge. Three kettles, one Burner, one RIMS heater.

Thoughts?

That is an option.

In my drawing, the MLT wouldn't need a heat source. Heat in the BK, and store in the HLT. That may not be viable, but is the thought process for the moment. Heat water in the BK-send to MT, Recirq RIMS, Heat water in BK and send to HLT to hold for sparge. Three kettles, one Burner, one RIMS heater.

Thoughts?

You would need a really well insulated HLT. I would personally forego the expensive tubing and get a burner for my HLT. Doesn't even need to be more than a turkey fryer at all.

Sawdustguy

Well-Known Member

You would need a really well insulated HLT. I would personally forego the expensive tubing and get a burner for my HLT. Doesn't even need to be more than a turkey fryer at all.

+1 I am not sure if it makes any sense to heat the water in the BK and store it in the HLT. If that is your intent, it is a waste of a vessel. If you want only one burner it makes sense to make a Brutus 20 setup and do away with the HLT. Otherwise if you have 3 vessels heat the HLT and BK and make life easy for yourself.

OK, I heading in another direction.

I want to make things easier on brewday, and need a small footprint structure.

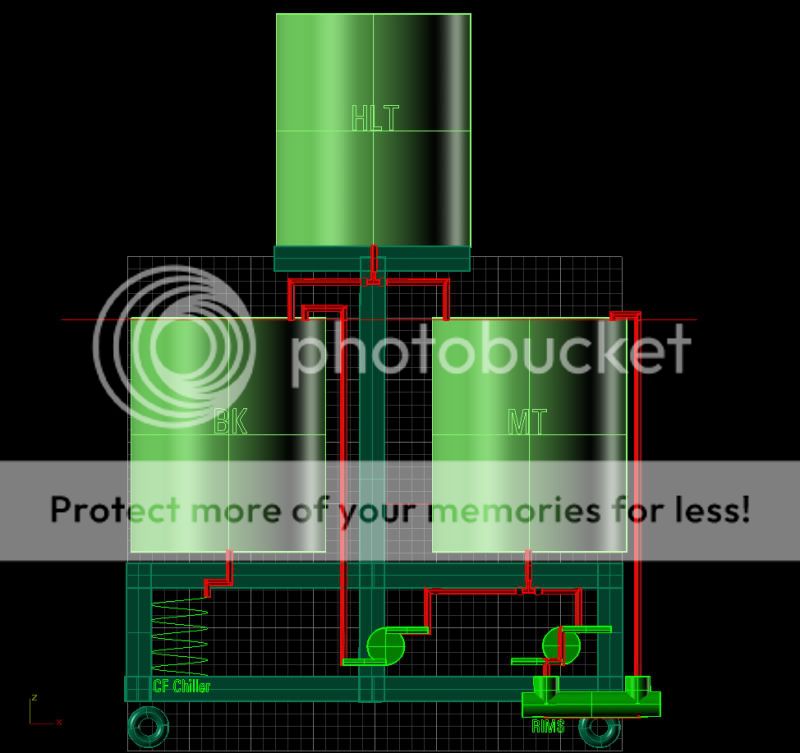

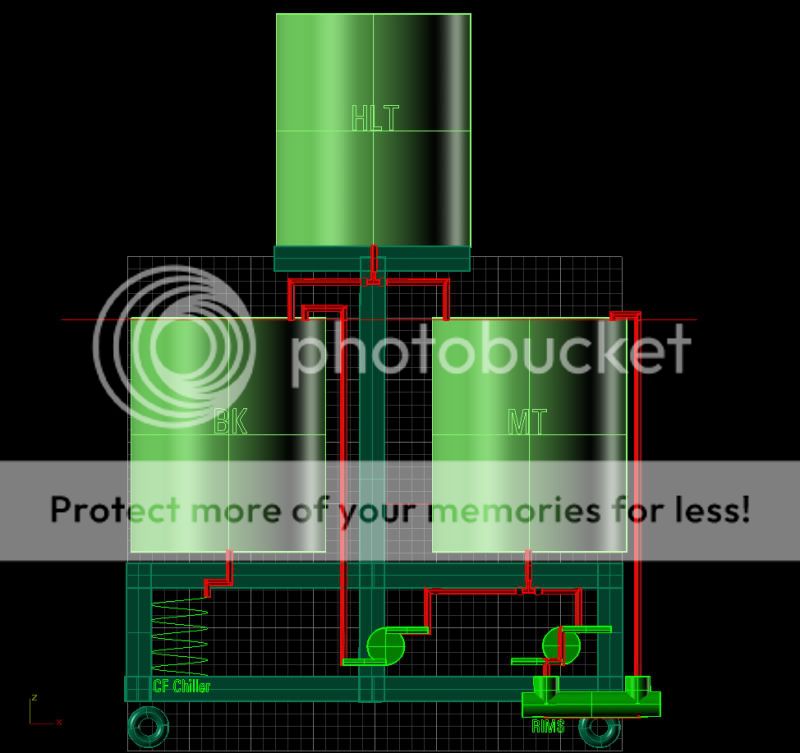

This thought process led me to this design. The HLT goes on top, but is not in the way of stirring in the MT or BK.

The HLT and the BK will be gas fired, and the MT electric RIMS.

Only a few valves to control flow. I will use 15g kettles, so that I can do 5 and 10 gal batches.

Any thoughts?

I want to make things easier on brewday, and need a small footprint structure.

This thought process led me to this design. The HLT goes on top, but is not in the way of stirring in the MT or BK.

The HLT and the BK will be gas fired, and the MT electric RIMS.

Only a few valves to control flow. I will use 15g kettles, so that I can do 5 and 10 gal batches.

Any thoughts?

Boerderij_Kabouter

Well-Known Member

Everything looks good but the second pump is useless. Just add a manifold or three way valve on the MLT pump. You will never be pumping simultaneously to the MLT and the BK.

How much control do you want?

How much control do you want?

Thats true. See, you just made it easier!

I Already have a Rims tube/PID/SSR, so I will probably use that, and I have 1 pump.

I need to decide Gas or electric. I will vary between 5 and 10 gal batches. What will that require for an electric elements?

I need to decide on a cooling system. (I now use a prechiller in ice, and a chiller in the BK) Thinking of maybe going to a plate chiller or Counterflow.

I Already have a Rims tube/PID/SSR, so I will probably use that, and I have 1 pump.

I need to decide Gas or electric. I will vary between 5 and 10 gal batches. What will that require for an electric elements?

I need to decide on a cooling system. (I now use a prechiller in ice, and a chiller in the BK) Thinking of maybe going to a plate chiller or Counterflow.

Boerderij_Kabouter

Well-Known Member

IMO, the simplest solution would be to use manual gas burners under the BK and the HLT. You can raise temps to strike temp easy enough by hand and you have the automation for the MLT with the RIMS. I think that is the easiest thing for you and is super easy to use. Just turn the burner on to heat.

Going E is a bit more involved, You would want to have 5500W or higher elements on 220VAC. Not hard, but less easy that connecting a gas line or tank and lighting it up.

Cooling is definitely a user preference. I love immersion chillers. Counterflow was nice, and I enjoyed mine while I had it. Plates work well but I think the maintenance and risk of crap stuck in them override any advantage at our scale. Of course that is just opinion. The plates works great and I haven't ever heard of an infection or anything from one. The one thing I will suggest is ice recirculation once your wort is below 140º. That really makes a difference on speed.

Going E is a bit more involved, You would want to have 5500W or higher elements on 220VAC. Not hard, but less easy that connecting a gas line or tank and lighting it up.

Cooling is definitely a user preference. I love immersion chillers. Counterflow was nice, and I enjoyed mine while I had it. Plates work well but I think the maintenance and risk of crap stuck in them override any advantage at our scale. Of course that is just opinion. The plates works great and I haven't ever heard of an infection or anything from one. The one thing I will suggest is ice recirculation once your wort is below 140º. That really makes a difference on speed.

Looks close to mine.. only mine isn't RIMS...

http://picasaweb.google.com/lh/photo/50DH5sOR-K9YIGtQ_YGN9A?feat=directlink

http://picasaweb.google.com/lh/photo/50DH5sOR-K9YIGtQ_YGN9A?feat=directlink

The plumbing is kind of complicated due to the desire to backflow the heat exchanger, and use all hard piping. I have seen much simpler plumbing for this kind of setup when an immersion chiller is used. With my setup, I am able to backflow the chiller in the event of a clog. Also, I whirlpool back into the kettle after it passes through the plate chiller. After I get to about 100 in the kettle, I begin to dump out @63-64F with chilled water.

The only thing I would change from this design is the chiller. I am in the process of making my own chiller, a tube shell design, which should improve efficiency. One could use a therminator and probably achieve great results though...but I never take the easy route. The mash tun isn't easy to empty out on 10g batches, but, unless you make a dumping bucket style mash, cleaning is never that easy.

I picked this style of setup after seeing a local homebrewer having a similar setup. It is compact, easy to disassemble and breaks down for storage/transportation easily.

I have plenty of pics, and can take many more, just PM me your email and I will share them.

Additionally, my dad and I built this system and have built a few for local homebrewers without any complaints at all.

The only thing I would change from this design is the chiller. I am in the process of making my own chiller, a tube shell design, which should improve efficiency. One could use a therminator and probably achieve great results though...but I never take the easy route. The mash tun isn't easy to empty out on 10g batches, but, unless you make a dumping bucket style mash, cleaning is never that easy.

I picked this style of setup after seeing a local homebrewer having a similar setup. It is compact, easy to disassemble and breaks down for storage/transportation easily.

I have plenty of pics, and can take many more, just PM me your email and I will share them.

Additionally, my dad and I built this system and have built a few for local homebrewers without any complaints at all.

Duffer

Well-Known Member

This is exactly my system. Two-tier. One pump and a manifold. Big burner for BK, cheapo burner on HLT, electric RIMS on mash with Cheap Auberins PID. Immersion chiller. With centrally located manifold outlets and long enough hoses with quick-disconnects, I can pump from any kettle to any other kettle if needed. (or for clean-up time)

so far, so good!

so far, so good!

Sawdustguy

Well-Known Member

This is exactly my system. Two-tier. One pump and a manifold. Big burner for BK, cheapo burner on HLT, electric RIMS on mash with Cheap Auberins PID. Immersion chiller. With centrally located manifold outlets and long enough hoses with quick-disconnects, I can pump from any kettle to any other kettle if needed. (or for clean-up time)

so far, so good!

Mine also. I wrote the RIMS for Dummies thread just for this purpose.

Layne, good job! You have simplified your brewery immensely and it should make life while brewing a whole lot easier for you.

Alright, you guys are gonna think I've flipped my lid, but after running this back and forth through my head, I think I'm leaning towards a 2 kettle electric rig.

I know, that 180 from where I was going, but it really would be great for my cookshack. I have spent the last month or so convincing myself why it wouldn't work (hard headed conventional wisdom... or lack there of)

I need to be able to do 5 and 10 gallon batches.

I brew inside, so it needs to be 'not messy'

It's gonna be in my Backyard Brewpub, so It's gotta look cool

I know, that 180 from where I was going, but it really would be great for my cookshack. I have spent the last month or so convincing myself why it wouldn't work (hard headed conventional wisdom... or lack there of)

I need to be able to do 5 and 10 gallon batches.

I brew inside, so it needs to be 'not messy'

It's gonna be in my Backyard Brewpub, so It's gotta look cool

thorongil

Well-Known Member

Sawdustguy

Well-Known Member

You could upsize something like my rig...

I think your system is really what he is looking for. He does need to be cognizant that his efficiency will be a little less than a batch sparge.

thorongil

Well-Known Member

Efficiency should not be too bad... I'm targeting 70% on my rig. Only ran one batch through so far, but I got 66% on that one...

I saw that the other day, and bookmarked it. I LOVE the cart idea. I have 2 of these in my cookshack already. We use them for everything.

Not sure about all the plumbing ( I know, earlier I said I wanted to turn valves instead of moving hoses. I told you I was wishy-washy).

I think you said this runs on 110v, and only does <5 gal batches.

I really want the ability to do 5 and 10 gal batches.

Not sure about all the plumbing ( I know, earlier I said I wanted to turn valves instead of moving hoses. I told you I was wishy-washy).

I think you said this runs on 110v, and only does <5 gal batches.

I really want the ability to do 5 and 10 gal batches.

thorongil

Well-Known Member

All you'd really need to do for 10 gallon batches is scale up the pots and the electric to 240V... and you'd need a bigger cart. Though I think you have enough space for a more permanent home... The basic design should work though.

Similar threads

- Replies

- 5

- Views

- 354

- Replies

- 3

- Views

- 479

- Replies

- 0

- Views

- 313

- Replies

- 39

- Views

- 937