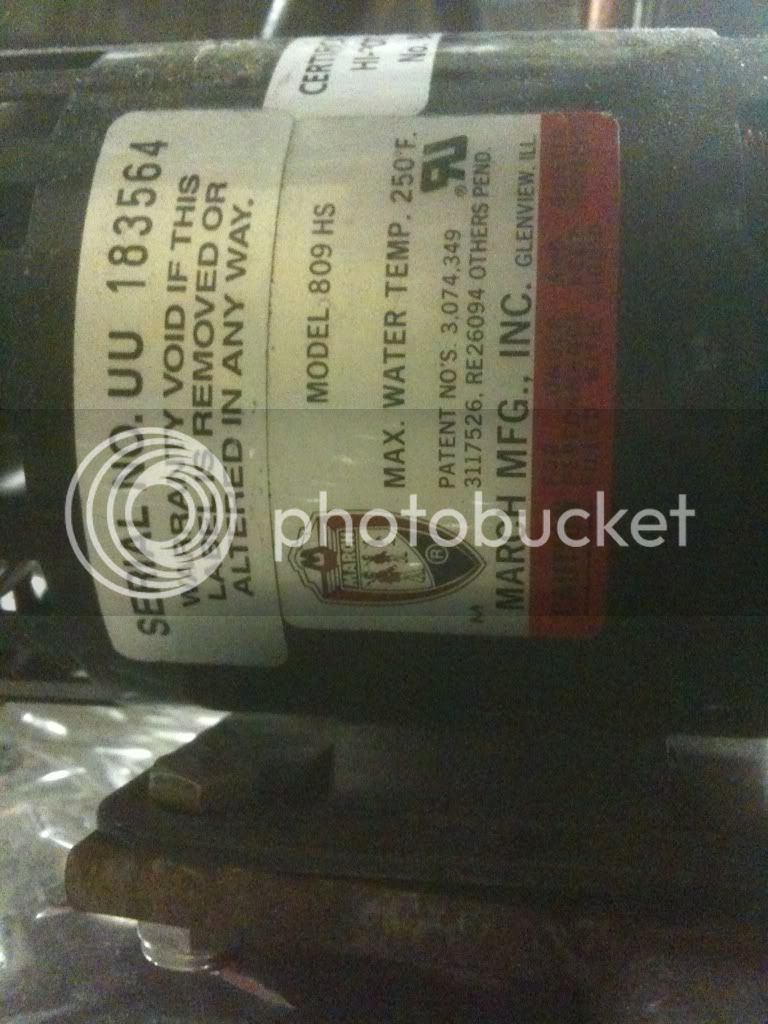

I have a typical March pump (809) I think (the kind they sale on Morebeer). Well I see they have a h315hf pump now that gives about 6 more feet of rise. I wonder if that is just a newly designed head that I might be able to buy and put on my current h315 (809) march pump?

Has anyone done this? If so, how much, and where would one just get the new 'HF' parts?

Thanks,

Ryan

Has anyone done this? If so, how much, and where would one just get the new 'HF' parts?

Thanks,

Ryan