celtic_dude

Well-Known Member

Hey. So recently I have been doing a lot of research on the whole electric brewing movement and I have to say that I want to do that  I have been a homebrewer for over 8 years and have been doing all grain batches for the last 3 years. But I have to say that I am getting tired of standing out in the cold or rain or snow while brewing on a sat/sun morning. Well recently I had to redo my basement due to mold and have and official unfinished side that I can do whatever I want with according to my wife

I have been a homebrewer for over 8 years and have been doing all grain batches for the last 3 years. But I have to say that I am getting tired of standing out in the cold or rain or snow while brewing on a sat/sun morning. Well recently I had to redo my basement due to mold and have and official unfinished side that I can do whatever I want with according to my wife  . So I would like to create an area where I can do my brewing indoors. Thankfully I was able to create my bar on the other side that has a double custom kegarator/fermentation chamber under the bar top.

. So I would like to create an area where I can do my brewing indoors. Thankfully I was able to create my bar on the other side that has a double custom kegarator/fermentation chamber under the bar top.

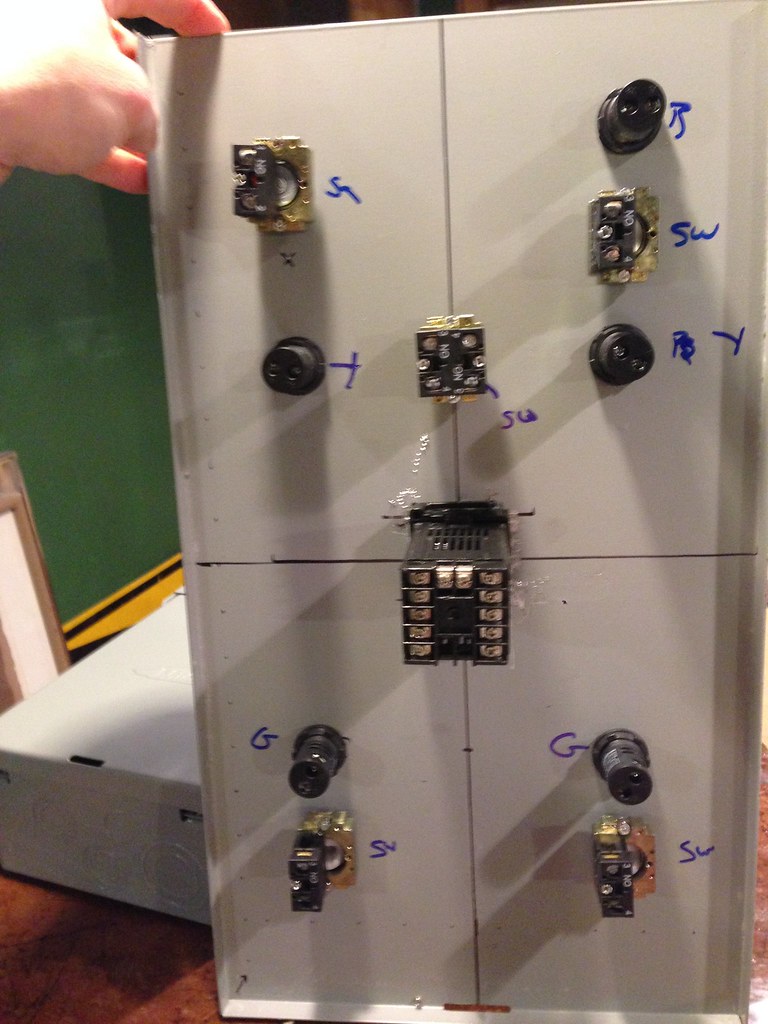

So I was thinking about designing my control box first. I feel that I can see myself wanting to have room to upgrade in the future and think that going bigger with the box to start is a good idea. I only have one boil kettle(8 gallon mega pot and 10g rubbermaid mlt) and dont' want to mess with them just yet so I think I will pick up a bigger kettle to work with that will allow 10gallon batches in the future and go Biab to start. But I want to have the flexibility to maybe go for a full herms system down the line. Anyone else ever do this? Was looking at the http://www.ebrewsupply.com/ebrew-kits/bcs-2-element-2-pumps-30a-kit-85.html kit or maybe piecing together my own.

Budget wise, I have about $500 to start with to make a control panel and one e-kettle (220v 5500w). Is that doable? My brother is going to run the 220v from the panel for me.

I feel like I have been reading through the http://www.theelectricbrewery.com site everyday but still a little confused. I would love to go as advanced as they are one day but want to start small but don't want to waste money on things that will not be used farther down. I want to plan for the big picture but make it functional sooner and smaller and add to as time goes by.

Thanks for your time and look forward to hearing back from you!

I have been a homebrewer for over 8 years and have been doing all grain batches for the last 3 years. But I have to say that I am getting tired of standing out in the cold or rain or snow while brewing on a sat/sun morning. Well recently I had to redo my basement due to mold and have and official unfinished side that I can do whatever I want with according to my wife

I have been a homebrewer for over 8 years and have been doing all grain batches for the last 3 years. But I have to say that I am getting tired of standing out in the cold or rain or snow while brewing on a sat/sun morning. Well recently I had to redo my basement due to mold and have and official unfinished side that I can do whatever I want with according to my wife So I was thinking about designing my control box first. I feel that I can see myself wanting to have room to upgrade in the future and think that going bigger with the box to start is a good idea. I only have one boil kettle(8 gallon mega pot and 10g rubbermaid mlt) and dont' want to mess with them just yet so I think I will pick up a bigger kettle to work with that will allow 10gallon batches in the future and go Biab to start. But I want to have the flexibility to maybe go for a full herms system down the line. Anyone else ever do this? Was looking at the http://www.ebrewsupply.com/ebrew-kits/bcs-2-element-2-pumps-30a-kit-85.html kit or maybe piecing together my own.

Budget wise, I have about $500 to start with to make a control panel and one e-kettle (220v 5500w). Is that doable? My brother is going to run the 220v from the panel for me.

I feel like I have been reading through the http://www.theelectricbrewery.com site everyday but still a little confused. I would love to go as advanced as they are one day but want to start small but don't want to waste money on things that will not be used farther down. I want to plan for the big picture but make it functional sooner and smaller and add to as time goes by.

Thanks for your time and look forward to hearing back from you!