It has been months since I started. I added a bunch of things, since the original wet test drive reared several design flaw monsters I went back and welded steel tops and reinforced burner cages/supports. I added a water filter that I had laying around. I am ready to brew. Let me know what you guys think. Thanks to all that have helped me with this project.

Front View

Lid additions to all keggles. MLT loc line for sparge arm through top for heat retention while mashing

New top plates with heat shield to protect heat exchanger wires. The wires are wrapped in silicone hose in the tube

new sparge arm I made to replace original design

Control panel. QD for temp sensor on left side

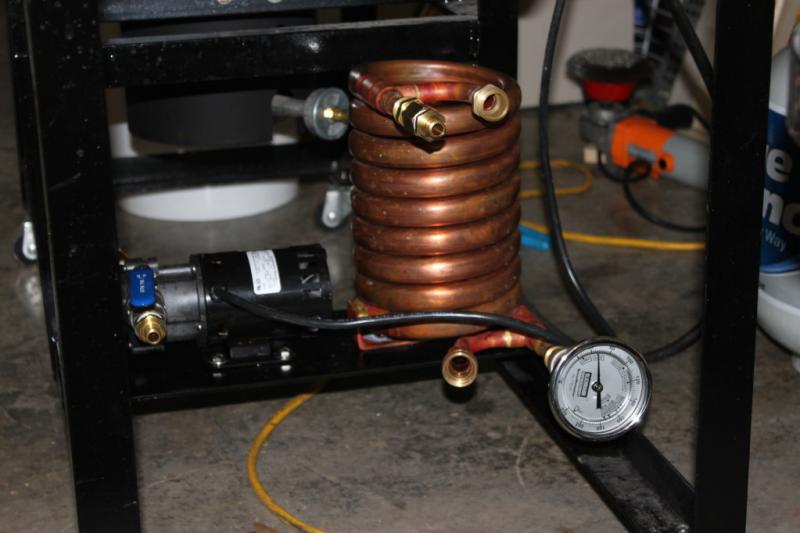

40 plate heat exchanger. O2 setup with SS QD for easy removal of unit from heat exchanger

New mash paddle I made out of maple

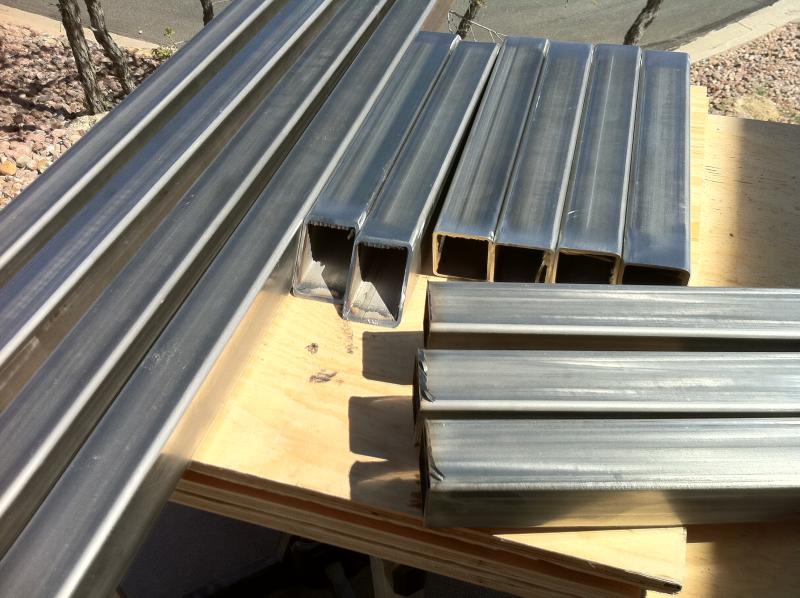

Top view of burner plates. Below the 10" I had to make some reinforcements out of 1/2" x 2 flat stock. On my first test runm the flame was lapping up the keg. I added the 1/8" steel plates with 10" circles plasma cut out of them and fired it up...the steel was melting and I about cried. I added the supports between the original burner cage and the 1/8" steel and welded them up...fired it up and no more melting.

Two 6' sections of silicone 1/2" hose eah with a female SS QD are all I require for fluid transfer. Everything is SS or copper...no brass anywhere except for the two flared end caps. It took me a few months of seperate purchases but I managed to get rid of all brass.

This thing should give me years of trouble free service.

I installed a piece of sheet metal between the tun and the top burner and fixed that little problem. My back is as happy as my taste buds now.

I installed a piece of sheet metal between the tun and the top burner and fixed that little problem. My back is as happy as my taste buds now.

!!

!!