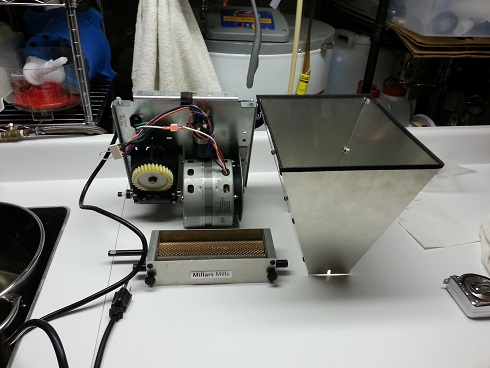

Not quite finished yet, but here's mine. Debating on paint or Formica (have both leftover from other projects) to finish it off.

It's the latest mill from Millars, 7" stainless rollers and ball bearings. Very nice unit. The motor is the one people snapped from from surplus supply for $8.95, and the table is an old steel printer table I've had lurking around for years. Best use I found for it yet!

I opted to mount the motor under the table and use the sprocket with a chain drive. The speed of the sprocket is 110 rpm, and I was able to get a smaller sprocket for the mill so it runs just under 145 rpm. With this arrangement there is measurable downward force on the mill shaft, where the ball bearings are superior, but I will be adding a pillowblock bearing at the sprocket to support it better, and a cover over the sprocket.

The space under the bucket is to store my scale, and the space under the motor fits the hopper. There is a round guide on the underside of the top to guide and capture the bucket with a slight friction fit so it stays put, and almost no dust escapes. Also missing is the cover over the motor assembly which has a double throw switch for Fwd-Off-Rev. The top is hinged on the back for 'storage' and to create a flat surface for the scale when I'm weighing out grains.

I've only used it once so far, and that was with pre-milled grain, but it powered through it no problem for that doubled milled BIAB brew. No more pre-milled grain for me!!

Some others using this same motor were concerned about overheating the motor, but it was cold to the touch after 12 lbs of pre-milled grain. I'll be keeping my eye (hand?) on it once I start running unmilled grain through it.

Project cost:

Mill - $164 (with shipping)

Motor - $20 (with shipping)

Sprocket & chain - $20

Switch - $15

Plywood - $13

Buckets - $8

Scale - $0 (part of a business lot purchase that was a steal for what I got)

Total: $240

Value: Priceless!