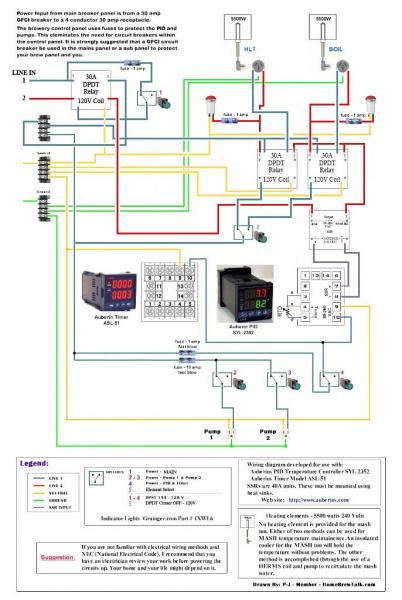

Inspired by many hours of reading this forum, I decided it was time to upgrade from my stove-top, gravity system to an all-electric setup. I was particularly intrigued by the build done by jsguitar, using a single PID to control 2 elements in separate vessels. So, I've spent my spare time the last couple of months putting this together.

My goals were to expand to 10 gal. batches, and eliminate the need for lifting large containers of hot liquid. Moving from the kitchen to the garage is a plus appreciated by SWIMBO, as well.

Many thanks go out to Kal, PJ, and all those contributing to the DIY and Electric Brewing forums, especially the Soldering Stainless Steel thread. I could never have even envisioned something like this without them.

The first run happened on New Year's Day, and was for the most part a huge success. After a few adjustments, the second run yesterday was nearly flawless. I now have 11 gals of Aberdeen Nut Brown Ale bubbling away int the fermentation chamber!

I'll post a few more pix as I get the chance.

My goals were to expand to 10 gal. batches, and eliminate the need for lifting large containers of hot liquid. Moving from the kitchen to the garage is a plus appreciated by SWIMBO, as well.

Many thanks go out to Kal, PJ, and all those contributing to the DIY and Electric Brewing forums, especially the Soldering Stainless Steel thread. I could never have even envisioned something like this without them.

The first run happened on New Year's Day, and was for the most part a huge success. After a few adjustments, the second run yesterday was nearly flawless. I now have 11 gals of Aberdeen Nut Brown Ale bubbling away int the fermentation chamber!

I'll post a few more pix as I get the chance.