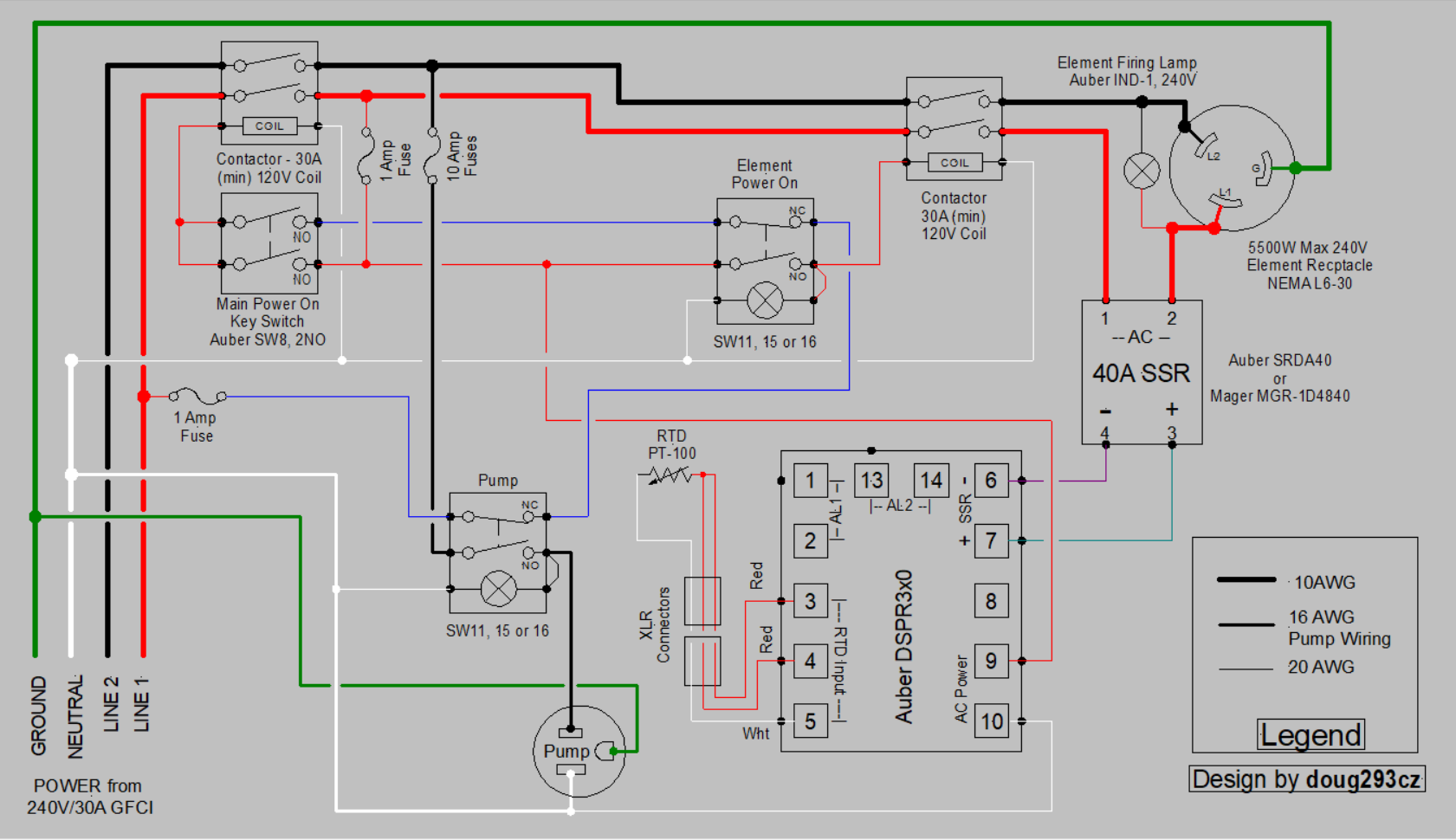

Currently i am running a small heat element 1k-2k off a 120v 20amp( i think, i will have to check) with a basic SCR on a 15gal BK only doing 5 gal batches mostly BIAB with a false bottom covering the element. as of right now i am not getting a decent boil due to the weak element (and would like to make double batches as well) so i want to up it to 240v. my plan is to use 220v 30A 3prong outlet. and build a control box similar to Georges from Barley and Hops with the PID(video linked below). though i am going to purchase a dernord 5500w element with the ground screw instead of rigging one like i had in the past. everything is essentially going to be the same except i will be using this 30 amp receptacal in the control box https://www.amazon.com/gp/product/B07RCLBV2B/ref=ox_sc_act_title_18?smid=AUGXZ0G0QW47K&psc=1. using 10/2 cable with 12 or 14 for the lower amp portion.

I need to add a weldless thermowell to the kettle to make this work and im still trying to find one and decide how long. a shorter one i think would work just as well but i am not sure. also was thinking it might be beneficial to get a 1/2inch weldless bulkhead and then just buy one to fit that. any suggestions on these would be much appreciated.

Has anyone built these? any issues? suggestions?

Thanks in advance, Cheers! Andy

I need to add a weldless thermowell to the kettle to make this work and im still trying to find one and decide how long. a shorter one i think would work just as well but i am not sure. also was thinking it might be beneficial to get a 1/2inch weldless bulkhead and then just buy one to fit that. any suggestions on these would be much appreciated.

Has anyone built these? any issues? suggestions?

Thanks in advance, Cheers! Andy

Last edited: