Brulosopher

Well-Known Member

- Joined

- Jun 1, 2011

- Messages

- 3,007

- Reaction score

- 447

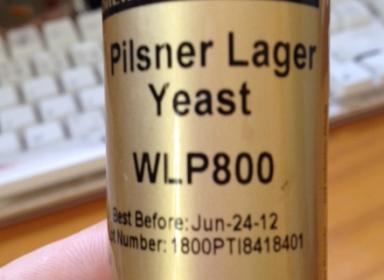

When making a starter for a pilsner, do I follow the same procedure as with ales? I'm most concerned about ferment temp. In 10 years of brewing, I've never brewed a lager... until next weekend. I just don't want to f*ck it up. I usually keep my starters on my counter (on a stir plate), which is 68-72F. I thought I recalled Jamil once saying lager starters should be done at standard starter temps, then chilled to pitching temp. Am I wrong?

Also, I usually start my ale starters 1-2 days before brewing. Is this the same for lagers? I was thinking 3-4 days might be more appropriate, given the fact the starter volume will be double my typical volume.

Thanks!

Also, I usually start my ale starters 1-2 days before brewing. Is this the same for lagers? I was thinking 3-4 days might be more appropriate, given the fact the starter volume will be double my typical volume.

Thanks!