Hello all. I am new to this forum and new to home brewing in general. however I am a beer drinking veteran lol.

Anyways. This is just my second batch, my first was a brown ale which I have high hopes for, I was initially worried because it foamed through my air lock and i didnt notice until it had dried out. but no signs of contamination and it smelled and tasted great when i bottled it.

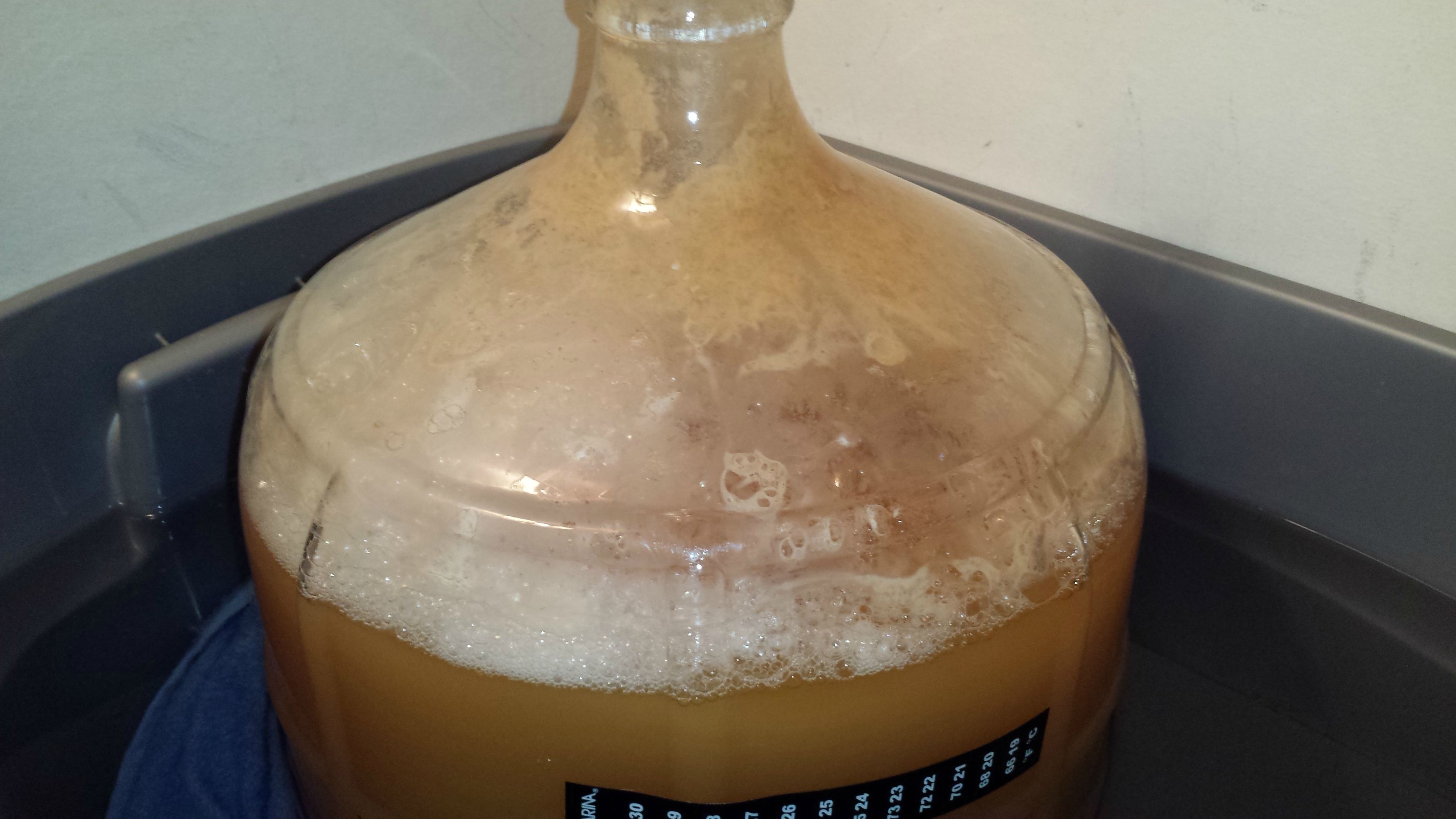

Anyways, the second beer I chose was a Home Brew brand kit, a Mexican Cerveza. I read that it is a lager and since I am not set up to lager a beer, I do not have high hopes to start. Learning from my first experience with overflow, I chose to go with a blow off tube into a container of sanitizer. When I checked out it this morning, the container had already foamed over and made a mess. I cleaned it up very sanitarily (word?) so no worries about that. But after some research, I found that the reason for my overactive fermentation may be temp. and it was. I was sitting around 77 F. I caught the problem and managed to rig up my AC in my closet to bring it down to around 68 F which i read was optimal.

TL;DR - My first 24 hours of primary were at a high temp of 77F, I caught it and have lowered it to 67F. Will that help me? or is most of the damage done? and since it is a lager, should i maintain an even lower tempterature for secondary?

Thanks, and I looks forward to continue to lurk around for tips and answers and try to contribute where I can.

- Rob

Edit 1: uploading a pic right now. my closet setup is pretty ghetto fabulous so i figured id share it. I wrapped the colander in a wet towel to bring the temp down before i had the AC in there.

Anyways. This is just my second batch, my first was a brown ale which I have high hopes for, I was initially worried because it foamed through my air lock and i didnt notice until it had dried out. but no signs of contamination and it smelled and tasted great when i bottled it.

Anyways, the second beer I chose was a Home Brew brand kit, a Mexican Cerveza. I read that it is a lager and since I am not set up to lager a beer, I do not have high hopes to start. Learning from my first experience with overflow, I chose to go with a blow off tube into a container of sanitizer. When I checked out it this morning, the container had already foamed over and made a mess. I cleaned it up very sanitarily (word?) so no worries about that. But after some research, I found that the reason for my overactive fermentation may be temp. and it was. I was sitting around 77 F. I caught the problem and managed to rig up my AC in my closet to bring it down to around 68 F which i read was optimal.

TL;DR - My first 24 hours of primary were at a high temp of 77F, I caught it and have lowered it to 67F. Will that help me? or is most of the damage done? and since it is a lager, should i maintain an even lower tempterature for secondary?

Thanks, and I looks forward to continue to lurk around for tips and answers and try to contribute where I can.

- Rob

Edit 1: uploading a pic right now. my closet setup is pretty ghetto fabulous so i figured id share it. I wrapped the colander in a wet towel to bring the temp down before i had the AC in there.