mopowers

Gearhead who likes beer

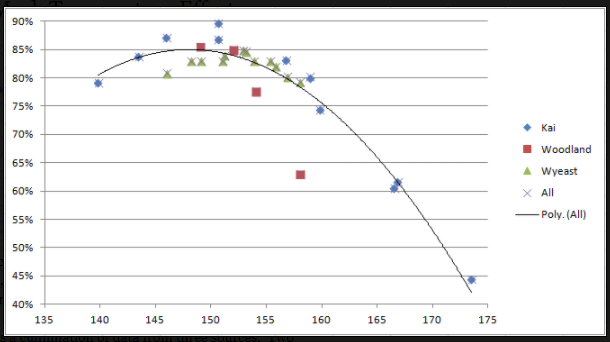

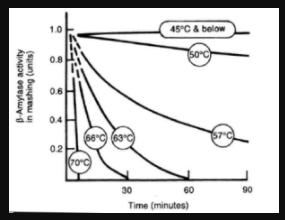

I'm still relatively new to homebrewing, so take it easy on me. We brewed a red ale recently and fermented with WLP004 Irish Ale yeast (our first time using this strain). We mashed at 152* and the OG was 1.060. It finished at 1.020 - a bit on the sweet side, for our taste. The beer is defenitely drinkable, but I'm just curious if this is typical attenuation for this particular yeast strain? We typically ferment with WLP090 and love the dry finish of that strain.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)