Interested in purchasing a decent malt mill motor. I've probably settled on a motor from All American Ale Works.

However, at the website I see

"NOTICE: Correct wiring of the Power Grinder grain mill motor is required. Wiring of the motor will vary depending on the application in which the motor is used (direction of shaft rotation and 110 V or 220 V). Consultation with a licensed electrician who is familiar with motor wiring is strongly recommended. "

Hmm...

I send email to [email protected] indicating I'm interested in purchasing a motor an ask for wiring info. In a reply I'm told to contact a professional electrician. Obviously, we have too many, ambulance chaser, lawyers and this is why All American Ale Works won't even provide a wiring schematic or info.

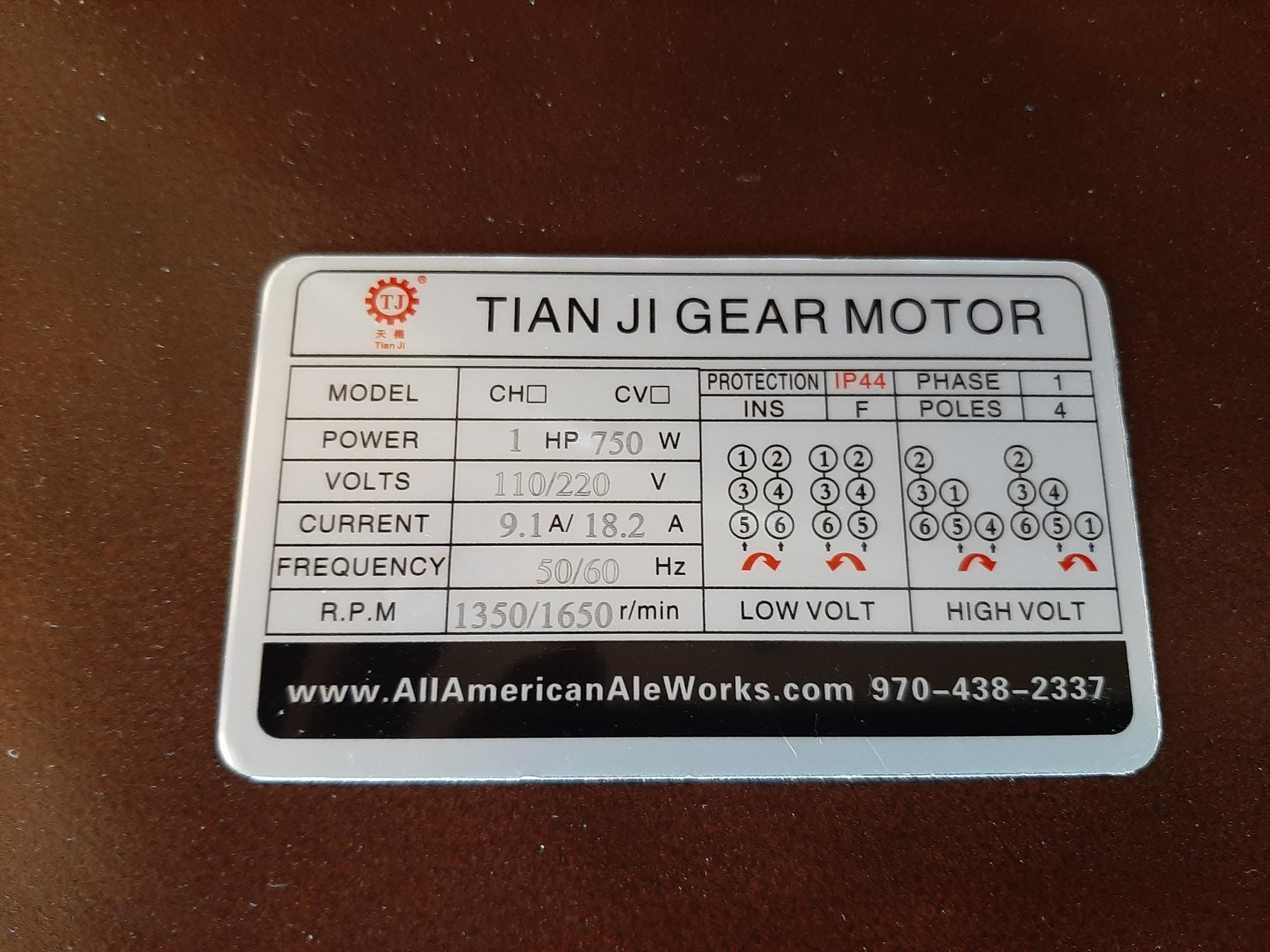

This leads me to my question. If I purchase a All American Aleworks motor, how do I wire the motor?

How do I wire the motor with a drum switch?

Thanks.

However, at the website I see

"NOTICE: Correct wiring of the Power Grinder grain mill motor is required. Wiring of the motor will vary depending on the application in which the motor is used (direction of shaft rotation and 110 V or 220 V). Consultation with a licensed electrician who is familiar with motor wiring is strongly recommended. "

Hmm...

I send email to [email protected] indicating I'm interested in purchasing a motor an ask for wiring info. In a reply I'm told to contact a professional electrician. Obviously, we have too many, ambulance chaser, lawyers and this is why All American Ale Works won't even provide a wiring schematic or info.

This leads me to my question. If I purchase a All American Aleworks motor, how do I wire the motor?

How do I wire the motor with a drum switch?

Thanks.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)