HungusBrews

Well-Known Member

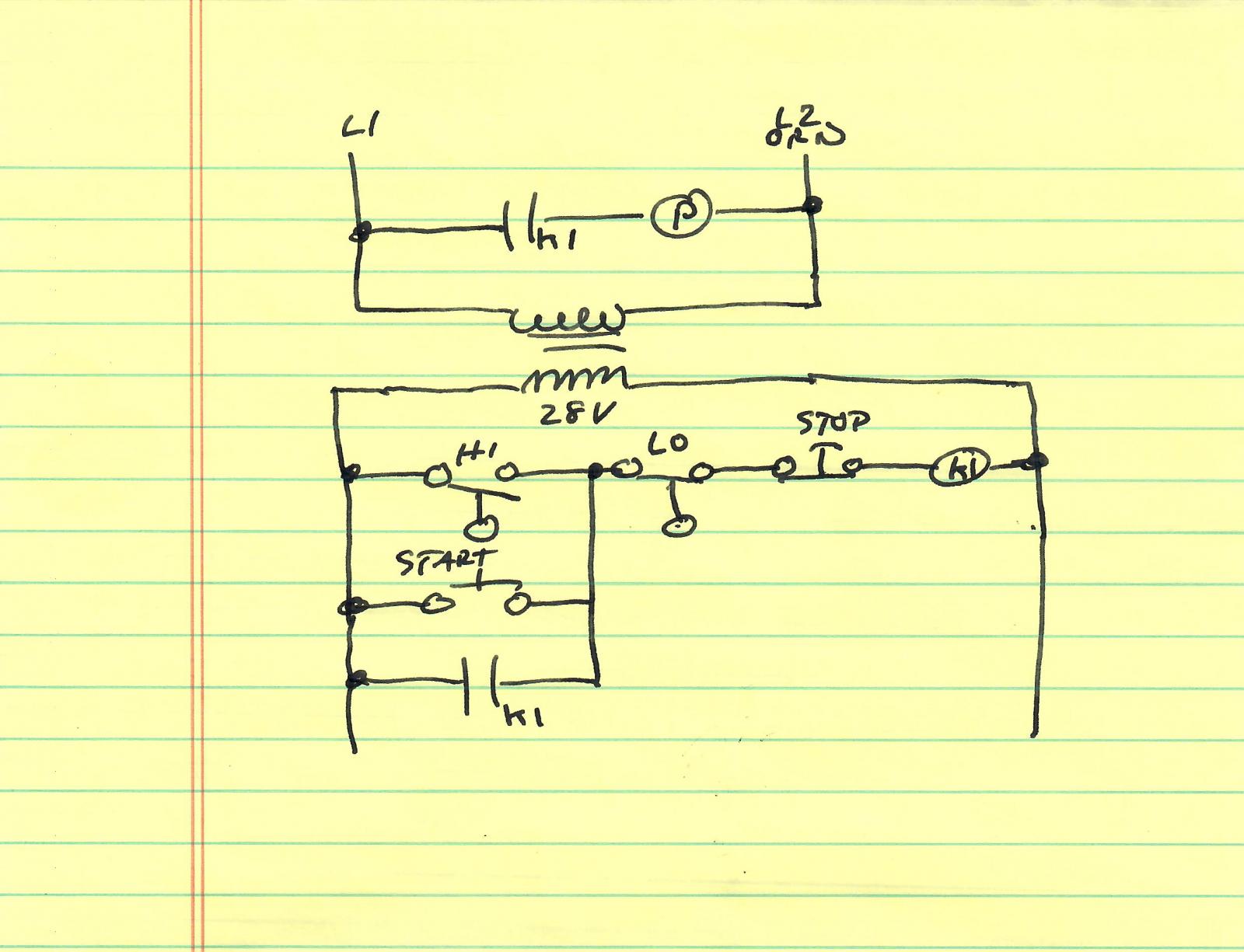

I am looking for advice on how I would wire up this dual ball float switch to control a march pump.

I currently use a BCS to control SSR's for my ferm chambers and fire a burner on my HLT so I have a pretty good understanding of basic SSR wiring. What I can't seem to wrap my head around is wiring a NC and a NO switch TOGETHER to turn a pump on and off. Do I use a DPDT relay? A DPST relay? I can use the 5V signal from the BCS as the power source.

This will be used in a grant that I am building and installed in the bottom. So the pump should turn on when the grant is full meaning the bottom and top floats are up. Then it should shut of when the grant is near empty when and both floats are down.

Any advice would be much appreciated! A link to a relay that would work would be even better. Once I have one in my hand I am sure I can figure it out.

I currently use a BCS to control SSR's for my ferm chambers and fire a burner on my HLT so I have a pretty good understanding of basic SSR wiring. What I can't seem to wrap my head around is wiring a NC and a NO switch TOGETHER to turn a pump on and off. Do I use a DPDT relay? A DPST relay? I can use the 5V signal from the BCS as the power source.

This will be used in a grant that I am building and installed in the bottom. So the pump should turn on when the grant is full meaning the bottom and top floats are up. Then it should shut of when the grant is near empty when and both floats are down.

Any advice would be much appreciated! A link to a relay that would work would be even better. Once I have one in my hand I am sure I can figure it out.

Last edited by a moderator: