You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why Not to Pitch On Your Yeast Cake

- Thread starter Bob

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Six_O_Turbo

Well-Known Member

Surprisingly this discussion has been about overly high pitching rates rather than about all the aspects of pitching on a yeast cake. While pitching too much yeast, or too little for that matter, will certainly alter the impression of the beer so will the dead yeast cells, break, and hop material left behind during the initial fermentation. Can someone shed some light on the effects of dead yeast, break, and hop matter leftover from the initial fermentation on the subsequent beer?

maskednegator

Well-Known Member

Over-pitching is always detrimental to the beer.

You're contradicting yourself here. You can't say that it's always bad but sometimes it's ok if you're deliberately trying to supress esters. "Always" and "sometimes" are mutually exclusive.we deliberately pitched more yeast than the following technique said we needed. This relative over-pitching, combined with temperature manipulation, deliberately suppressed ester formation. By manipulating the cell counts at inoculation we could produce the same flavor effect as switching strains entirely.

Bob

Well-Known Member

LOL, Obviously we interpret some of your sources differently.

On the contrary, we interpret them exactly the same.

Which is precisely in line, if a little below, what the math tells us in my original post for a "normal" gravity wort (1.048). That's why he says "minimum".From Designing Great Beers (1996,2000 - Ray Daniels):

"As a general rule, homebrewers pitch far less yeast than they should. Evidence of this comes form the standard packages of yeast sold for homebrewing use. They Generally contiain only a small percentage of the total yeast population needed to achieve recommended pitching rates."

"On a commercial scale, good brewing practice calls for pitching no less than 10 million yeast cells per millimeter of wort. That's approximately 200 billion yeast cells in a 5 gallon batch. This minimum (emphasis mine) amount is intended for "normal" gravity worts, and those with a higher OG will need even more yeast."

So thanks for proving my point by quoting my source back at me. If that wasn't your intent, you're going to have to be a little more clear.

While I don't know for sure, I can only assume the context of the podcast was for inoculating a "big" beer. Regardless, on Mr Malty, in BYO, and many other places, JZ advocates for pitching at a proper rate. One podcast, possibly taken out of context, does not overthrow all the rest of his writing.Jamil has talked favorably about pitching onto a yeast cake in at least one podcast that I recall.

I've spoken of relatively high pitching rates, too. I agree there's a time and place for it. What's your point?Jamil and John talk favorably of high pitching rates in Brewing Classic Styles as well on pages 24-25.

You are entitled to your opinion. Brewers and brewing scientists far more experienced than either you or I disagree. Guess who I'm going to agree with?This isn't intended as a "your wrong" post, because you obviously are experienced in the subject, But stating "Over-pitching is always detrimental to the beer." is just inaccurate.

You're contradicting yourself here. You can't say that it's always bad but sometimes it's ok if you're deliberately trying to supress esters. "Always" and "sometimes" are mutually exclusive.

There's no contradiction at all. Calculated over-pitching, where you target a specific pitch in order to achieve a desirable effect without the ill effects of over-pitching, is perfectly acceptable. In fact, one could argue that it's really not "over-pitching" in the purest sense of the term, because you're not pitching over what you've determined to be an acceptable amount, but that teeters on the pedantic. Uncalculated over-pitching, where you have no control over the pitch rate - like knocking out onto a yeast cake - is not acceptable, because, not knowing the pitch rate, it is impossible to predict or even estimate the impact on the beer.

There's a fine line you can walk if you know what you're doing. If you're just dumping wort into a container with heaven knows how much yeast in it, you don't know what you're doing - because you have no control over one of your ingredients.

It's a fine distinction, but it nevertheless exists.

Regards,

Bob

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

permo

Well-Known Member

I will also say that this has been a fantastic thread and I appreciate the information.

the only time I pitch on a yeast cake is when my OG is 1.090 or greater and I want a neutral flavor profile. Strong Scotch Ale, Barley Wine, IIPA...etc..etc..

Does intentional overpitching encourage extreme attenuation? I am thinking that it does...

the only time I pitch on a yeast cake is when my OG is 1.090 or greater and I want a neutral flavor profile. Strong Scotch Ale, Barley Wine, IIPA...etc..etc..

Does intentional overpitching encourage extreme attenuation? I am thinking that it does...

mojotele

Well-Known Member

Does intentional overpitching encourage extreme attenuation? I am thinking that it does...

From one of Bob's previous posts:

Attenuation is, to the best of my knowledge, not affected by over-pitching. In other words, pitching more than the required amount of yeast will not increase attenuation.

I can see how it would possibly increase the rate of fermentation, but I can also understand how it wouldn't increase attenuation.

slowbie

Well-Known Member

Bob, you are quickly becoming one of my favorite posters on this forum. Thanks for presenting good, well researched information in a non-inflammatory way.

meddin

Well-Known Member

+1 on the sticky vote

Bob

Well-Known Member

Thanks, guys. I just got sick of writing the same thing in a dozen different threads. Figured I'd put it in one central location.

Cheers!

Bob

Cheers!

Bob

Attenuation is, to the best of my knowledge, not affected by over-pitching. In other words, pitching more than the required amount of yeast will not increase attenuation. There are many factors at work in attenuation, more than simply a surplus of yeast will accommodate.

The ability of the particular strain to metabolize different sugars, and the presence of sugars in the wort (accessible to yeast) are more important than how many cells are present. In other words, if you have a surplus of sugars which your yeast cannot metabolize, no increase in colony size will attenuate those sugars. For example, you could put five pounds of slurry in a 5-gallon batch of beer rich with lactose and no real difference in attenuation would be seen.

Attenuation can be adversely affected by underpitching; the literature is clear on that issue.

Make sense?

Bob

I agree with this post but I do have experiment results that confuses the issue for me. Four samples pitched with dry yeast at recommended rates following both dry pitch and rehydration as well as O2 injection vs. none all ended up with FG = 1.014 and what I was expecting. The control sample pitched at 14x recommended rates ended up FG = 1.010.

The "recommend" rate was .5 grams per 1/2 gallon wort as calculated from a recommended pitch of 11grams for 5 gallons. Were the samples underpitched or does a gross overpitch really attenuate more?

I agree with this post but I do have experiment results that confuses the issue for me. Four samples pitched with dry yeast at recommended rates following both dry pitch and rehydration as well as O2 injection vs. none all ended up with FG = 1.014 and what I was expecting. The control sample pitched at 14x recommended rates ended up FG = 1.010.

The "recommend" rate was .5 grams per 1/2 gallon wort as calculated from a recommended pitch of 11grams for 5 gallons. Were the samples underpitched or does a gross overpitch really attenuate more?

How did the overpitched sample taste?

I have to find my tasting notes to be sure but I'm pretty sure it was the most "clean" one of the five samples just as you'd expect.

SpanishCastleAle

Well-Known Member

Good write-up Bob. Kaiser did some experimenting with this and made a thread about it (too lazy to look it up...not too lazy to wash my cakes and pitch a measured amount from them  ). IIRC, his experiment was inconclusive but as I recall he found contradictory info on it (like Denny posted earlier itt). His research led him to believe that homebrewers and pros were on opposite ends of the spectrum (i.e. homebrewers often believe under-pitching increases esters but the pros believe over-pitching increases esters).

). IIRC, his experiment was inconclusive but as I recall he found contradictory info on it (like Denny posted earlier itt). His research led him to believe that homebrewers and pros were on opposite ends of the spectrum (i.e. homebrewers often believe under-pitching increases esters but the pros believe over-pitching increases esters).

Another thing I don't like about over pitching onto a cake is that you had all that extra yeast that could have been saved for another batch.

Lastly, I can't remember where I read it but I thought I read that the final cell count in a batch of beer made from wort of a given gravity/composition was fairly constant regardless of pitch rate (unless way too low). IOW, the yeast only multiply to a certain count and the original pitch rate determines how much growth that needs to occur to hit that count. That might help explain why it doesn't really affect attenuation unless you way underpitch. BTW, I don't think what I just wrote is inconsistent with Berrriffic's earlier post where he said:

EDIT: Here's Kaiser's experiment from his BrauKaiser page but the thread he made here had some good discussion. HBT Search is not working for me so I can't look it up.

EDIT2: Found a thread on it here. On the first page of that thread I provided a link to some of the other threads I mentioned above.

Another thing I don't like about over pitching onto a cake is that you had all that extra yeast that could have been saved for another batch.

Lastly, I can't remember where I read it but I thought I read that the final cell count in a batch of beer made from wort of a given gravity/composition was fairly constant regardless of pitch rate (unless way too low). IOW, the yeast only multiply to a certain count and the original pitch rate determines how much growth that needs to occur to hit that count. That might help explain why it doesn't really affect attenuation unless you way underpitch. BTW, I don't think what I just wrote is inconsistent with Berrriffic's earlier post where he said:

Due to the bolded word.Yeast tend to replicate 3-5 times from the correct pitching number to the final number in the beer.

EDIT: Here's Kaiser's experiment from his BrauKaiser page but the thread he made here had some good discussion. HBT Search is not working for me so I can't look it up.

EDIT2: Found a thread on it here. On the first page of that thread I provided a link to some of the other threads I mentioned above.

nutty_gnome

Well-Known Member

I would like some clarification to make this information applicable in practice.

I wash yeast. After I wash, I get what is essentially a cylinder of creamy tan yeast at the bottom of my jar. I can calculate the volume of a cylinder and find out how many milliliters of washed yeast cake I have.

What I want to know is: If in our 12 plato, 5 gallon example, I was supposed to pitch 228ml of slurry, can I get the same results by pitching a washed yeast cake that is 1/4 that volume (in this example 57ml of washed yeast cake). Or did I misunderstand the satement in the thread that a cake contains 4 times more yeast by volume than a slurry?

This information would help me to know what size jars to wash yeast into so I could gauge how much I'm pitching. N_G

I wash yeast. After I wash, I get what is essentially a cylinder of creamy tan yeast at the bottom of my jar. I can calculate the volume of a cylinder and find out how many milliliters of washed yeast cake I have.

What I want to know is: If in our 12 plato, 5 gallon example, I was supposed to pitch 228ml of slurry, can I get the same results by pitching a washed yeast cake that is 1/4 that volume (in this example 57ml of washed yeast cake). Or did I misunderstand the satement in the thread that a cake contains 4 times more yeast by volume than a slurry?

This information would help me to know what size jars to wash yeast into so I could gauge how much I'm pitching. N_G

conpewter

Well-Known Member

Might be useful to weight the carboy before making your "Starter beer" of a normal gravity, then when you rack off that and are ready to put your big beer on it, you can weigh it again and determine how much yeast slurry is there and if you need to pour any of it off.

BioBeing

Well-Known Member

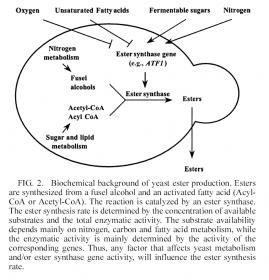

OK, no argument, but some discussion, OK? You say "When you over-pitch the colony doesn't need to reproduce. Thus measurably fewer esters are produced." Dr. Clayton Cone of Lallemand says pretty much the opposite...."ester production is related to yeast growth but not in the way you might think. The key element to yeast growth and ester production is acyl Co-A. It is necessary for both yeast growth and ester production. When it is busy with yeast growth, during the early part of the fermentation, it is not available for ester production. Ester production is directly related to biomass production. Everything that increases biomass production (intensive aeration, sufficient amount of unsaturated fatty acids, stirring) decreases ester production. The more biomass that is produced the more Co-enzyme A is used and therefore not available for ester production. Anything that inhibits or slows down yeast growth usually causes an increase in ester production: low nutrient, low O2." The full article is at http://www.danstaryeast.com/library/yeast-growth. Care to comment?

I had an issue with this, based on what I know about coenzyme A from studying lipid synthesis in other systems. Acetyl-CoA levels in most systems do not vary much in different growth states. This apparently holds true for yeast too [Yoshioka and Hashimoto (1984) Agric. Biol. Chem. 48; 207-209].

In delving a bit deeper, acetyl-CoA, acyl-CoAs and fusel alcohols are required to make the flavor active acetate esters. The enzymes that put these together are called ester synthases, the major one being ATF1. The transcription of the gene encoding ATF1 appears to be key step in the process, and is regulated in a complex manner: it is inhibited by oxygen and unsaturated fatty acids; and activated by fermentable sugars and nitrogen. Anything that affects the activity of these synthases will affect the ester formation.

Here is a review I am plodding through... Flavor-active esters: adding fruitiness to beer. Let me know if you cannot get the pdf They are talking about this mainly in the context of high gravity lagers, that get diluted prior to packaging, which is apparently how most lagers are commercially made! High gravity worts lead to increased ester production, although addition of maltose instead of glucose can diminish this effect. All very complicated!

Wondering if the practice of using yeast cake in the event of stuck fermentation has a place here?

See thread: https://www.homebrewtalk.com/f13/psa-foolproof-stuck-ferment-fixer-72072/

As Evan! says in this thread, despite best practices in proper yeast pitching, sometimes the FG isn't as low as one would like. When pitching a beer that is 80-90% fermented onto a cake, I would think that disadvantages discussed when using the cake as a primary fermentation method would be minimized?

Hope this qualifies as discussion, not disagreement.

I agree with you. In that case, since you're not aerating the beer to encourage yeast growth, you need to use as much yeast as you can.

BioBeing

Well-Known Member

Bit more reading... Acetate esters mentioned above are only one form of volatile ester that contribute to flavour. The next class are the ethyl esters.

Acetate esters: (in which the acid group is acetate and the alcohol group is ethanol or a complex alcohol derived from amino acid metabolism)

Ethyl esters (in which the alcohol group is ethanol and the acid group is a medium-chain fatty acid [MCFA])

Ethyl ester production appears to be a bit less studied, but seems primarily depended on the amount of medium chain fatty acids present. Ethyl esters tend to follow the same pattern as acetate esters, except they do not change with the sugar content of the wort and adding unsaturated fatty acids leads to a decrease in ethyl ester production. Increasing the temp of the fermentation increases the amount of acetate esters more than ethyl esters. In fact, ethyl hexanoate levels hardly change between 20 and 26*C.

Acetate esters: (in which the acid group is acetate and the alcohol group is ethanol or a complex alcohol derived from amino acid metabolism)

- ethyl acetate (solvent like aroma),

- isoamyl acetate (banana aroma),

- phenyl ethyl acetate (roses, honey).

Ethyl esters (in which the alcohol group is ethanol and the acid group is a medium-chain fatty acid [MCFA])

- ethyl hexanoate (anise seed, applelike aroma),

- ethyl octanoate (sour apple aroma)

- ethyl decanoate (floral odor).

Ethyl ester production appears to be a bit less studied, but seems primarily depended on the amount of medium chain fatty acids present. Ethyl esters tend to follow the same pattern as acetate esters, except they do not change with the sugar content of the wort and adding unsaturated fatty acids leads to a decrease in ethyl ester production. Increasing the temp of the fermentation increases the amount of acetate esters more than ethyl esters. In fact, ethyl hexanoate levels hardly change between 20 and 26*C.

Paddle_Head

Well-Known Member

I would like some clarification to make this information applicable in practice.

I wash yeast. After I wash, I get what is essentially a cylinder of creamy tan yeast at the bottom of my jar. I can calculate the volume of a cylinder and find out how many milliliters of washed yeast cake I have.

What I want to know is: If in our 12 plato, 5 gallon example, I was supposed to pitch 228ml of slurry, can I get the same results by pitching a washed yeast cake that is 1/4 that volume (in this example 57ml of washed yeast cake). Or did I misunderstand the satement in the thread that a cake contains 4 times more yeast by volume than a slurry?

This information would help me to know what size jars to wash yeast into so I could gauge how much I'm pitching. N_G

I have similar questions.

I guess I'm struggling with the concept of slurry concentration.

For example, I wash my yeast using the technique from the sticky at the top of this page. I start with an initial volume of ~64 oz of water to mix up my yeast cake, and end up after all the settling & transfers with 8oz sample jars of very clean looking yeast. Now if I diluted with 40 oz of water initially, that slurry would be much more concentrated in the final 8oz jar. Or if I made my slurry with the same amount of water, but a washed yeast from a sample with a much higher OG, there would be much more yeast suspended in that initial 64oz of slurry.

I understand the concept of counting cells with a microscope, as well as various other plating/microscopic techniques for quantifying bacterial load. All of which seem a bit more of an investment in time/$'s than I'd care to make.

I do think the idea of quantifying a washed and compressed amount of yeast seems pretty robust. Maybe using a graduated cylinder at some point in the starter process?

Also no idea if prolonged refrigerated storage would dilute viability over time either of yeast.

I have to find my tasting notes to be sure but I'm pretty sure it was the most "clean" one of the five samples just as you'd expect.

Please find them...I would be really interested in the aeration vs none results too.

cheezydemon3

Well-Known Member

I have been dumping out 1/2 to 2/3 of my yeast cake for about a year now and pitching on that.

I guess I make better beer, but I have improved other techniques.

Did we need a whole thread for.... POUR OUT SOME OF THAT HUGE CAKE DUDE!!!

Not too scientific, but I shoot for half of a typical cake.

I guess I make better beer, but I have improved other techniques.

Did we need a whole thread for.... POUR OUT SOME OF THAT HUGE CAKE DUDE!!!

Not too scientific, but I shoot for half of a typical cake.

mdwmonster

Well-Known Member

As I read this, I'm begining to think that washing yeast might be something worth trying. Any idea how long the yeast will last? Seems like every batch of beer I brew calls for a different yeast, but if possible, I'd like to start keeping some on hand (if for no other reason than to give me something else beer related to mess with).

Also, I assume when you are talking about the volume of the yeast, you are refering to just the yeast settlement at the bottom, and not the full volume of the starter/washed yeast jar.....right?

Also, I assume when you are talking about the volume of the yeast, you are refering to just the yeast settlement at the bottom, and not the full volume of the starter/washed yeast jar.....right?

slowbie

Well-Known Member

As I read this, I'm begining to think that washing yeast might be something worth trying. Any idea how long the yeast will last? Seems like every batch of beer I brew calls for a different yeast, but if possible, I'd like to start keeping some on hand (if for no other reason than to give me something else beer related to mess with).

Also, I assume when you are talking about the volume of the yeast, you are refering to just the yeast settlement at the bottom, and not the full volume of the starter/washed yeast jar.....right?

According to the stickied thread on yeast washing, Bernie Brewer has used yeast as old as a year. The specific post is here.

Otherwise, please don't cloud the issue.]

Don't cloud the issue? On this newsgroup? AHHHHHHhaha

hahahahahahahahahahahahaaaaaaaaaaaaaaaaa!!!

Second, tasters have observed thin beer, beer lacking in body and mouthfeel. To be perfectly honest, the exact cause of this effect is unknown, but it is strongly correlated with over-pitched yeast, so a connection is highly likely.

Well, if there are more yeast working on the wort, then even

if that yeast is not particularly efficient at breaking down

some particular sugar, if there are enough of them, you

will still get more attenuation. Aren't the yeasts that give

you less attenuation also quick flocculators?

I wouldn't pitch onto a yeast cake because of the trub, but

if someone wants to, as another poster said, just dump out

some of it.

Ray

Paddle_Head

Well-Known Member

According to the stickied thread on yeast washing, Bernie Brewer has used yeast as old as a year. The specific post is here.

Yep. There is a thread somewhere on making a "yeast bank" if you'd like to store yeast for >1 year.

Edit: Here it is-

https://www.homebrewtalk.com/f13/guide-making-frozen-yeast-bank-35891/

bad practice?

Isn't that entirely subjective?

In Belgium there's a Trappist or Abby brewery that sends buckets of it's spent yeast cake to the local pubs where people will mix it in their beer or take a shot straight.

!!~ YECH ~!! But it's all subjective.

I won't be mixing spent yeast with beer 'cause I don't like it. But bad practice? What if they like it ?

Isn't that entirely subjective?

In Belgium there's a Trappist or Abby brewery that sends buckets of it's spent yeast cake to the local pubs where people will mix it in their beer or take a shot straight.

!!~ YECH ~!! But it's all subjective.

I won't be mixing spent yeast with beer 'cause I don't like it. But bad practice? What if they like it ?

gtpro

Well-Known Member

The only problem is I got a pretty busy schedule and I just dont think I have time to count to a billion.

Honestly, I would only consider washing specialty liquid yeast that costs $8-9 per dose, with Safale or notty, the dollar or two well worth pitching fresh.

Honestly, I would only consider washing specialty liquid yeast that costs $8-9 per dose, with Safale or notty, the dollar or two well worth pitching fresh.

Bob

Well-Known Member

BioBeing - Thanks for the enzyme studies! That's, like, Wow!

Theoretically, as the slurry in the starter flask has a much higher concentration of yeast solids, this would be true. According to Fix - and other researchers have borne this out - only 25% of the average mixed-material slurry is yeast solids. A starter slurry will have non-yeast solids too, but you'd need to do a series of cell counts to determine a baseline for your setup.

What's important is the cell count.

That's why it's a Rule of Thumb, not something hard and fast.

Your technique may make a runny slurry, it may make a thick slurry. Different yeasts will also present different physical characteristics. For example, Wyeast 3787 is runny, like pancake batter, while 1187 is rather thicker, sort of like pancake batter after several seconds on the griddle. (That's a lame metaphor, but it's the best I can think of off the top of my head!)

If you want to seriously quantify cell counts the only real way to do it is with a hemocytometer and a microscope.

According to the sources and my experience, viability of harvested, unwashed slurry drops off precipitously over time. In the OP I noted 25% per each seven days stored. What that works out to be for washed yeast, I really can't say; I have no data from which to draw conclusions.

Regardless of calculated storage, some degradation is bound to occur over time, whether it's washed or simply harvested. The wise brewer will build up a starter from his stored yeast and pitch the slurry from that.

Correct.

Good question! Apparently, and in the absence of contrary data, the answer would be "Yes." The samples were not underpitched.

Presumably the gross overpitch simply sent the colony into overdrive, metabolizing everything they possibly could. That's the only thing I can imagine.

That's not a brewing practice. That's a thing drinkers do. Has nothing to do with brewing practice.

What equates with good or bad brewing practice is not subjective. There are standards. Ask Dr Bamforth.

Cheers, folks! Great discussion!

Bob

I would like some clarification to make this information applicable in practice. I wash yeast. After I wash, I get what is essentially a cylinder of creamy tan yeast at the bottom of my jar. I can calculate the volume of a cylinder and find out how many milliliters of washed yeast cake I have.

What I want to know is: If in our 12 plato, 5 gallon example, I was supposed to pitch 228ml of slurry, can I get the same results by pitching a washed yeast cake that is 1/4 that volume (in this example 57ml of washed yeast cake). Or did I misunderstand the satement in the thread that a cake contains 4 times more yeast by volume than a slurry?

This information would help me to know what size jars to wash yeast into so I could gauge how much I'm pitching. N_G

Theoretically, as the slurry in the starter flask has a much higher concentration of yeast solids, this would be true. According to Fix - and other researchers have borne this out - only 25% of the average mixed-material slurry is yeast solids. A starter slurry will have non-yeast solids too, but you'd need to do a series of cell counts to determine a baseline for your setup.

What's important is the cell count.

I guess I'm struggling with the concept of slurry concentration.

That's why it's a Rule of Thumb, not something hard and fast.

Your technique may make a runny slurry, it may make a thick slurry. Different yeasts will also present different physical characteristics. For example, Wyeast 3787 is runny, like pancake batter, while 1187 is rather thicker, sort of like pancake batter after several seconds on the griddle. (That's a lame metaphor, but it's the best I can think of off the top of my head!)

If you want to seriously quantify cell counts the only real way to do it is with a hemocytometer and a microscope.

Also no idea if prolonged refrigerated storage would dilute viability over time either of yeast.

According to the sources and my experience, viability of harvested, unwashed slurry drops off precipitously over time. In the OP I noted 25% per each seven days stored. What that works out to be for washed yeast, I really can't say; I have no data from which to draw conclusions.

As I read this, I'm begining to think that washing yeast might be something worth trying. Any idea how long the yeast will last? Seems like every batch of beer I brew calls for a different yeast, but if possible, I'd like to start keeping some on hand (if for no other reason than to give me something else beer related to mess with).

Regardless of calculated storage, some degradation is bound to occur over time, whether it's washed or simply harvested. The wise brewer will build up a starter from his stored yeast and pitch the slurry from that.

Also, I assume when you are talking about the volume of the yeast, you are refering to just the yeast settlement at the bottom, and not the full volume of the starter/washed yeast jar.....right?

Correct.

The "recommend" rate was .5 grams per 1/2 gallon wort as calculated from a recommended pitch of 11grams for 5 gallons. Were the samples underpitched or does a gross overpitch really attenuate more?

Good question! Apparently, and in the absence of contrary data, the answer would be "Yes." The samples were not underpitched.

Presumably the gross overpitch simply sent the colony into overdrive, metabolizing everything they possibly could. That's the only thing I can imagine.

bad practice?

Isn't that entirely subjective?

In Belgium there's a Trappist or Abby brewery that sends buckets of it's spent yeast cake to the local pubs where people will mix it in their beer or take a shot straight.

!!~ YECH ~!! But it's all subjective.

I won't be mixing spent yeast with beer 'cause I don't like it. But bad practice? What if they like it ?

That's not a brewing practice. That's a thing drinkers do. Has nothing to do with brewing practice.

What equates with good or bad brewing practice is not subjective. There are standards. Ask Dr Bamforth.

Cheers, folks! Great discussion!

Bob

Similar threads

- Replies

- 10

- Views

- 443

- Replies

- 13

- Views

- 867

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)