Nice setup and your thoughtful rationale for the system was much better (more thoughtful) then the previous comments. I can see what you are saying and thats a nice brewing space. Looks clean and I like how you have it all set up.

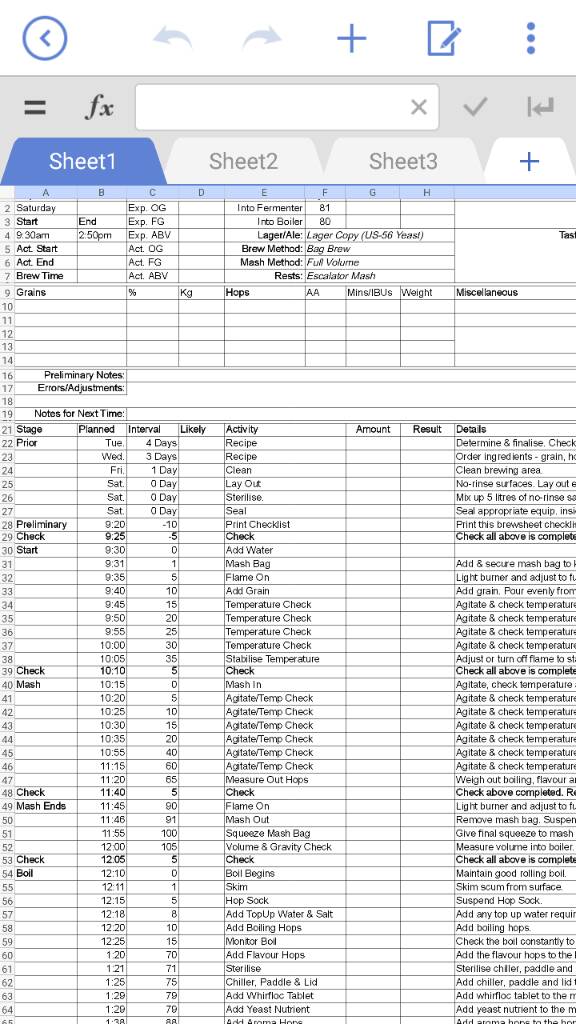

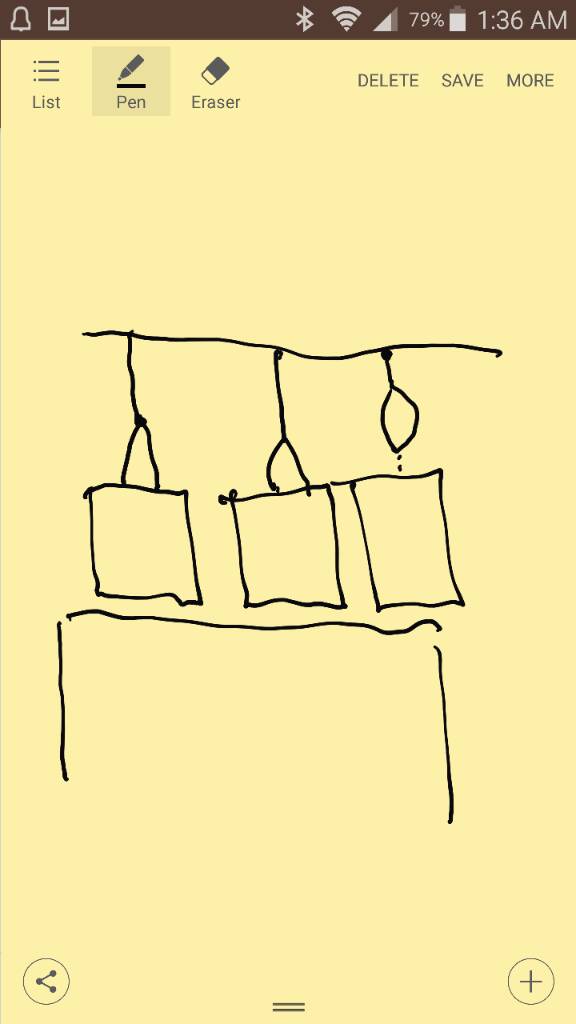

Consider this. Obviously you are not going to change but you could easily put eye hooks in that ceiling. With one above each kettle and a wench to help you, you could easily brew 30g at a time. If you can run all those elements at once or run them somehow consecutively while one is mashing, I could produce 30g of beer on that same system in around 3 hours with a 45 minute mash and boil. You would simply heat to strike, line pot with bag, mash, hoist bag, let drip, boil, done. Then with large enough grain bills you could parti gyle each one with a simple dunk sparge and produce 60g in 4 hrs. Or with a large enough kettle, maybe 35 gallons and or using one of those pots you could just make 1bl at a time in about 3 hours. There are many paths up this mountain and they all lead to the top. I understand your clear beer needs and rationale, but wanted to at least let you know what was possible. Here is a wonderful pic showing. I think you would go from bag to can and clean up would be easy.

What about this. You dont biab, you use a bag as a filter. You mash in in two kettles that have bags. The third is empty. When the first mash is up you pump the runnings into the empty kettle and batch sparge. You run that into the third kettle. Now you simply squeeze, so batch sparge with squeeze (good efficiency iiac), and remove bag. How convenient right, just lift grains out. Now you pump the second mash first runnings into now empty middle pot and batch and squeeze the second mash, then boil. Boom, 30g, in very little time. Not biab at all just using the bag as a filter, which I can assure you the good bags like wilser are likely as fine as any false bottom. You could do the same batch sparging without bag but man it would be harder do get grains out I can only imagine. Even if you dont use any ideas the bag might aid you in that system as a secondary filter, and make the grains easier to clean.

View attachment 605481

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)