[OT sidebar] I love my Micromatic stout faucet - but it has a known failure mode that can be user-aggravated.

Do not make a habit of pulling the faucet lever to its natural, ~90° stop, as that excessively stretches the rubber diaphragm and accelerates the fatal cracking thereof. When that happens, your stout will gush through the top of the body and there's nothing you'll be able to do to stop it save for popping its keg connector off. Bt/dt, total freak show with the wife trying to catch the gusher while I snuck an arm under the keezer lid to pop the QD

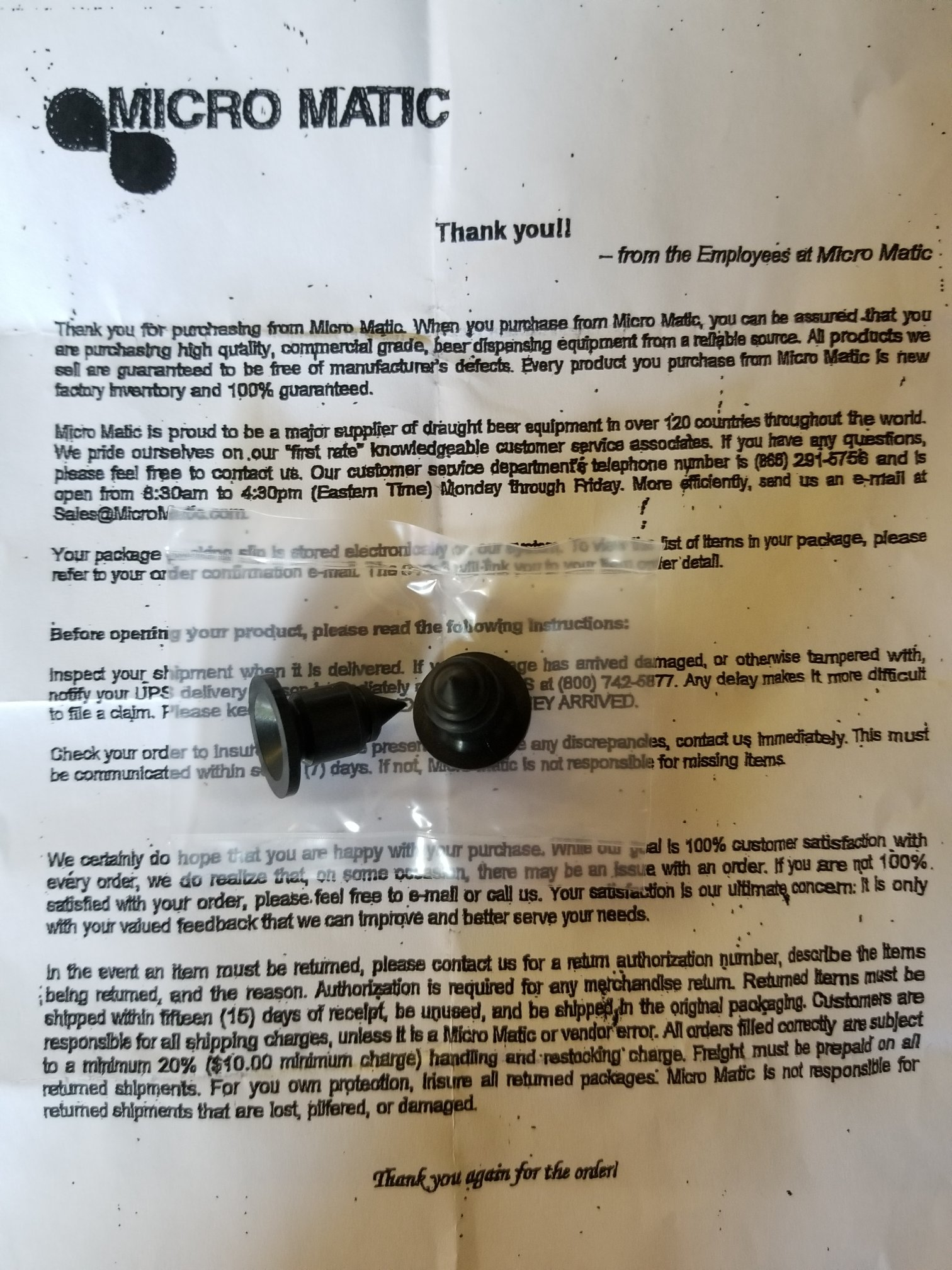

Anyway, here's the cure. I recommend buying one or two in advance(!)

Keep the travel to a max of 45° off vertical. You can observe there's a bevel, maybe 30° - on the front side of the lever arm - that literally does nothing functionally, but it is a decent reference...

Cheers!

Do not make a habit of pulling the faucet lever to its natural, ~90° stop, as that excessively stretches the rubber diaphragm and accelerates the fatal cracking thereof. When that happens, your stout will gush through the top of the body and there's nothing you'll be able to do to stop it save for popping its keg connector off. Bt/dt, total freak show with the wife trying to catch the gusher while I snuck an arm under the keezer lid to pop the QD

Anyway, here's the cure. I recommend buying one or two in advance(!)

Keep the travel to a max of 45° off vertical. You can observe there's a bevel, maybe 30° - on the front side of the lever arm - that literally does nothing functionally, but it is a decent reference...

Cheers!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)