SteveH aka shetc

Well-Known Member

- Joined

- Jul 28, 2013

- Messages

- 3,151

- Reaction score

- 5,675

Hi All,

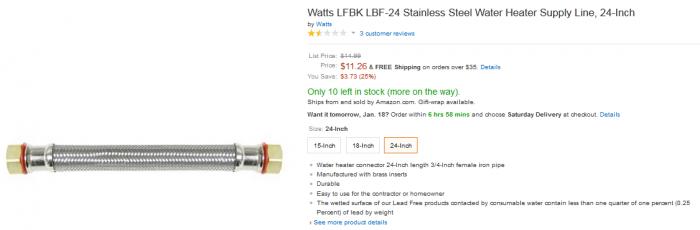

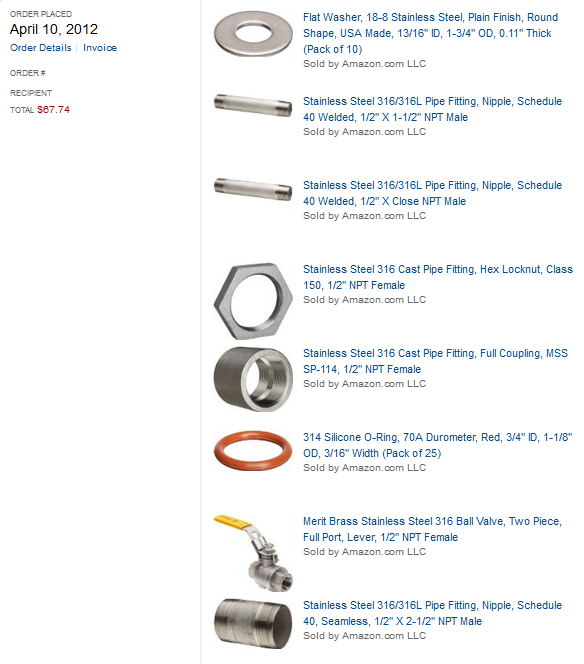

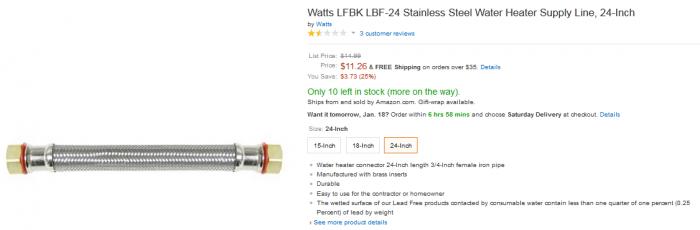

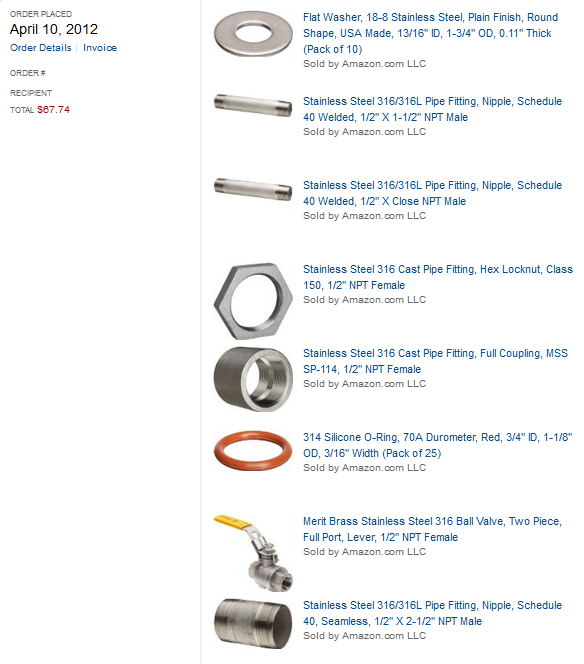

A co-worker asked me if I would be interested in buying his DIY cooler mash tun system as he has just bought a newer system. The photos below show that he spent about $120 on the parts. What would be a fair offer for this used system?

Thanks,

Steve

A co-worker asked me if I would be interested in buying his DIY cooler mash tun system as he has just bought a newer system. The photos below show that he spent about $120 on the parts. What would be a fair offer for this used system?

Thanks,

Steve

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)