Beer Viking

Beer Lover

I thought that finding iodine on amazon would be simple but there seem to be a lot of different kinds. What is the right one for checking to see if I'm done mashing at an hour in?

Thanks!

Thanks!

I think just the regular drugstore-type of iodine tincture is all you need

Thanks. Do you use it yourself or just skip it?

I thought that finding iodine on amazon would be simple but there seem to be a lot of different kinds. What is the right one for checking to see if I'm done mashing at an hour in?

Thanks!

Stick your finger in the mash liquid

(but keep in mind only gel'd starch will indicate, which gets me thinking how effective it'd be for a adjunct batch. without a cereal mash))

(but keep in mind only gel'd starch will indicate, which gets me thinking how effective it'd be for a adjunct batch. without a cereal mash))if it's cold enough for that, you might need an iodine test!

(but keep in mind only gel'd starch will indicate, which gets me thinking how effective it'd be for a adjunct batch. without a cereal mash))

60 is fineGreat information guys! I think I'll skip it altogether and just do 90 min mashes unless 60 would be fine?

I strongly agree that monitoring the SG of the wort in the mash is the best test for determining percentage of conversion. This is best done with a refractometer, as the samples are only a few drops, and cool quickly to a testable temp. I have attached spreadsheets below that show max possible wort SG vs. mash thickness (qt/lb) assuming a grain potential of 80% (1.037), which is close enough for most typical mashes that are less than ~10% crystal, roast, etc. Approximate formulas for percent conversion (i.e. conversion efficiency) are:A better indication of conversion is your pre-boil gravity. Any unconverted starches will end up dropping out as trub anyway. As long as you have good pH and temperature control and allow sufficient time for the enzymes to do their thing, you should be in good shape.

On the other hand, iodophor is my go-to sanitizing solution and certainly will react with any residual starch on my gear.

If the grain bits in the sample fail the test, that means you still have unconverted starch in the grain bits - the mash isn't "done." Any soluble starch that is in the wort only lasts a few minutes at most before it is reduced to fragments short enough to pass the test (assuming you still have adequate enzyme levels in the wort.)Skip it. If there is a little debris in the test, they will be a false positive. If you kept your temp and time, it will be converted. We do 90 min mashes just to insure.

It becomes more of an issue if you're mashing with a lot of adjuncts, and/or your base malt has low diastatic power. Otherwise, the vast majority of conversion is complete in about 20 minutes. In 60 minutes, you should be fine.

If I wanted to do a Kölsch or a hefeweizen would 60 still be ok?

Fine crush and thin mash both increase the enzymes' ability to convert starch to sugar by making more of the grain accessible...

How is "thin" your mash? What is ratio grist to water (approx)?

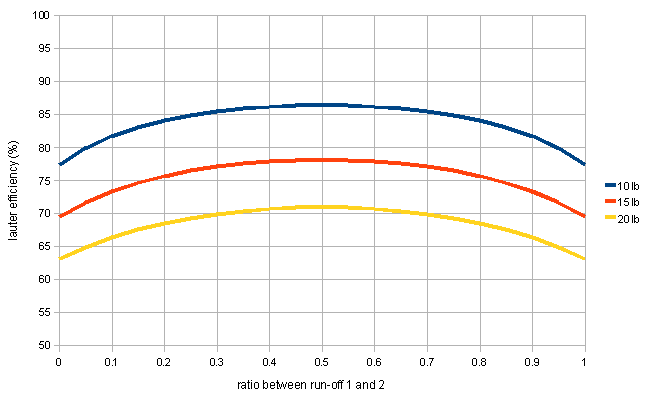

Correct, exact run-off volume ratio is not critical for getting near optimal lauter efficiency when batch sparging. Anywhere from 60:40 to 40:60 will give results that you won't be able to detect the difference between. Here's a graph from Kai Troester (Braukaiser) that shows how lauter efficiency varies with run-off volume ratio. 0 is no sparge, and 0.5 is equal run-off volumes. The graph also shows how lauter efficiency varies with grain bill size assuming the same pre-boil volume for all cases.I do BIAB with *almost* full volume mash... 6 Gal batches.. So for my 12-15ish lb grain bills I do roughly 8 g total water.... I jigger my mash volumes (using Brewtarget brewing software) so that I have about 6.5 gallons of strike, and 1.5 gallons of dunk sparge in a separate smaller kettle...

It works out to about 2.25 -2.5 quarts/lb depending on grain bill, etc.

I think the math works out better to do 2 equivalent runoffs... (i.e.strike - loss=1st run off. 2nd runoff about equal to 1st, adjust as required) but it's more convenient for me to use a 1.5g dunk... So that's

what I do....

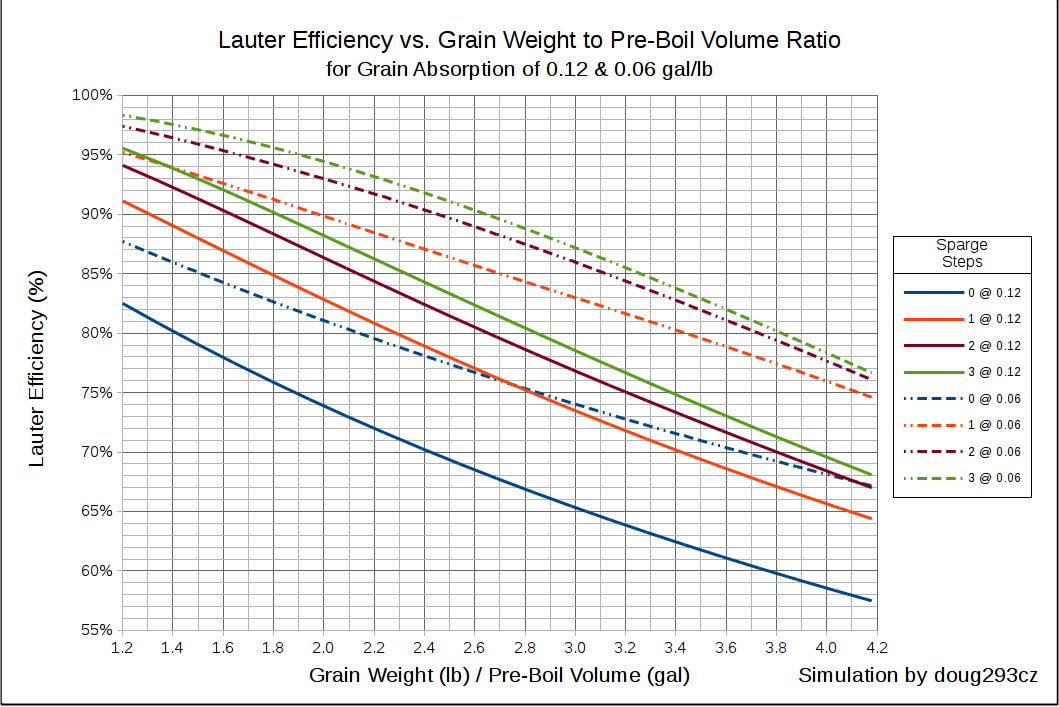

The exact ratio isn't critical, but you can find some theoretical plots on here, that show the max extraction for various sparge scenarios... @doug293cz has done them I think...