Daniel B

Member

- Joined

- Apr 19, 2020

- Messages

- 9

- Reaction score

- 9

I've made a batch of "Winter Bock" which I based on a simple extract recipe kit. Everything went well and all the sugar I dumped in there did its job in terms of OG.

The yeast I used was two slap-packs of Wyeast 1007 in one can of Propper Starter and water for 24 hours on a stir plate. Aerated with air for an hour after pitching.

I'm fermenting in a good ol' bucket with maybe less headroom than intended (lotta foam in the airlock hose those first two days). The bucket is in a chest freezer with an inkbird controlling the cool side. I haven't sprung for a heater yet, but perhaps I should.

So now to the question: my fermentation seems to be stuck at 1.050, should I sanitarily pitch some yeast to finish off the sugar? I think those poor ale yeast were unprepared for such a high OG or something (just pure speculation).

Here's my options as I see them:

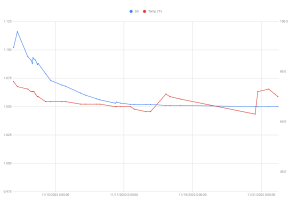

Below (spoilered for size) is the progress over time. Those temperature spikes are me noticing the ambient temp going down below 62 and placing a container of hot water in the freezer with it to slowly warm the whole system.

Bonus questions so I can always learn more and do better:

The yeast I used was two slap-packs of Wyeast 1007 in one can of Propper Starter and water for 24 hours on a stir plate. Aerated with air for an hour after pitching.

I'm fermenting in a good ol' bucket with maybe less headroom than intended (lotta foam in the airlock hose those first two days). The bucket is in a chest freezer with an inkbird controlling the cool side. I haven't sprung for a heater yet, but perhaps I should.

So now to the question: my fermentation seems to be stuck at 1.050, should I sanitarily pitch some yeast to finish off the sugar? I think those poor ale yeast were unprepared for such a high OG or something (just pure speculation).

Here's my options as I see them:

- Do nothing, wait another week (will happen regardless), and hope the beer isn't a sugary mess (the wort tasted awesome, so it can't be that bad).

- Get some high-abv tolerant belgian yeast and see if they can chew through the rest of those sugars.

- Pitch some champagne yeast (is sucrose too complex for them?) and see if they can drive the OG down.

Below (spoilered for size) is the progress over time. Those temperature spikes are me noticing the ambient temp going down below 62 and placing a container of hot water in the freezer with it to slowly warm the whole system.

Bonus questions so I can always learn more and do better:

- Do you lose a lot of yeast in foam to lack of headroom and is it enough to materially affect the fermentation?

- Does high sugar hurt the yeast at all or just high alcohol?

- Should I have used two cans of starter to make my double starter?

- Is there ever any benefit in adding extra yeast? I read a thread where posters here claimed that they would be outcompeted by existing yeast in there but it seems like if the existing ones were dormant the new ones would seize the opportunity.

- Should I be worried about carbonation in bottling if I've accidentally hammered my yeast population?

- General feedback?

Attachments

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)