Not directly for beer, but husband and I just finished flight of the bumblebee cleaning of the house before the notary public comes by tomorrow afternoon for the ritual signing of the refinance papers. Mopped up the sticky spots on the kitchen floor that get tracked in from the brewery, found a missing airlock, and a random growler that I left next to the woodstove to soak out the dried crap in the bottom. Also bought a new heavy-duty mop head for the garage floor to mop up after brewdays. Still looking for that damned keg lube...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

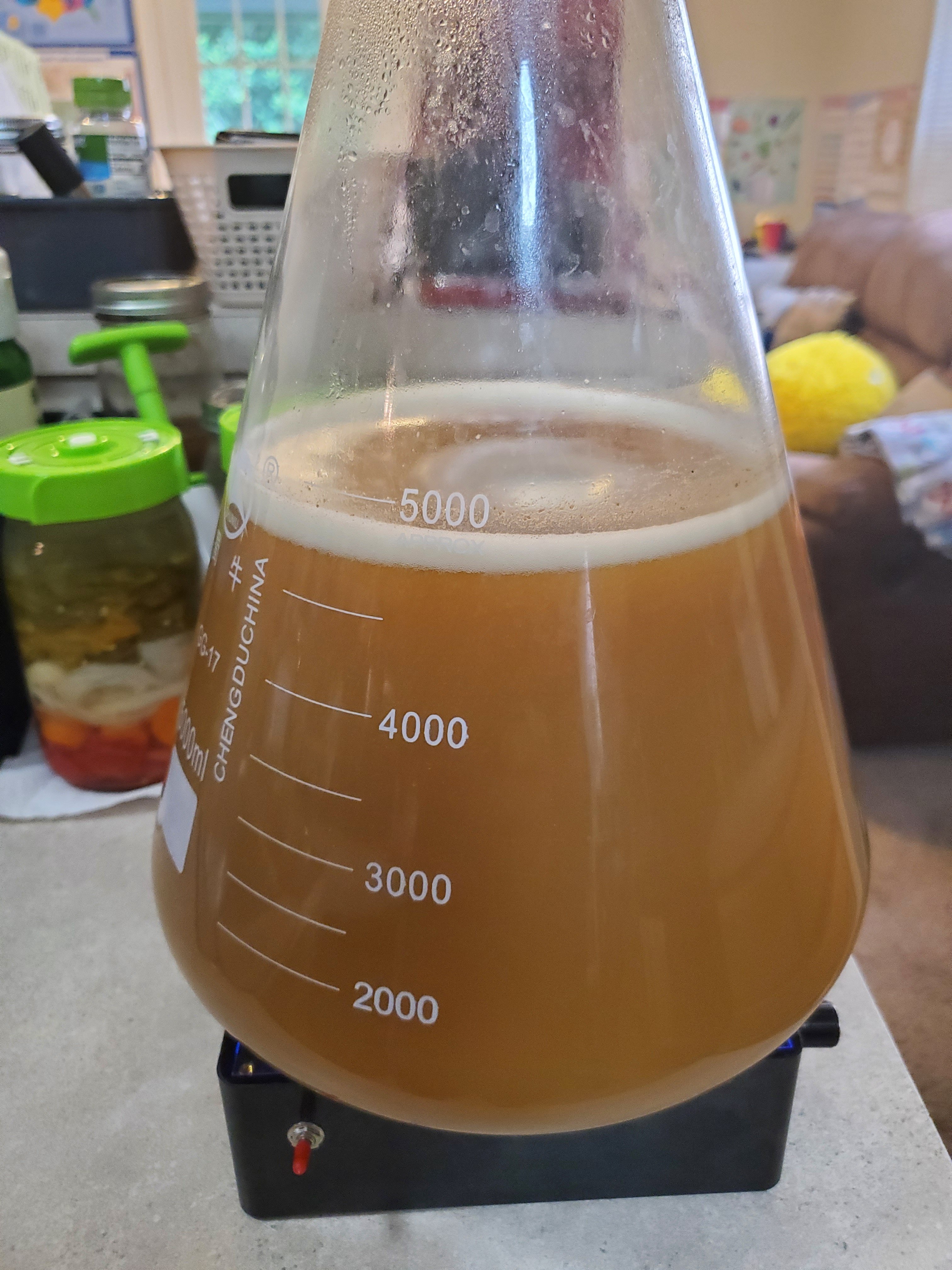

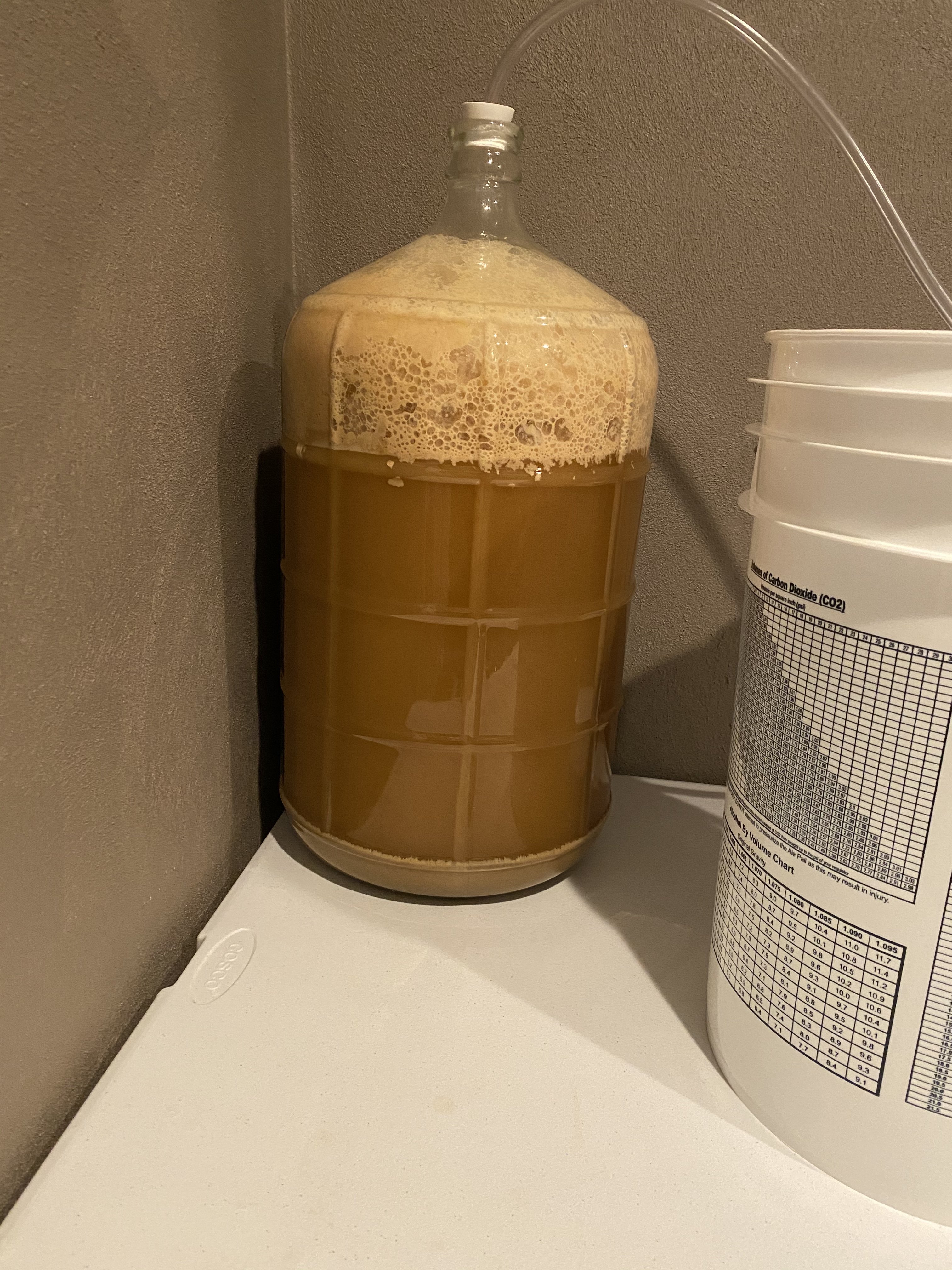

You are probably spot on. Aerated quite a bit w an O2 wand. Pitched cold slurry into wort @ 65. Original pic was taken about an hour after pitching. Looks a lot more normal this morning. You’re right about the headspace too!!I've had a few slurry pitches where the slurry/trub just about hit the halfway mark on the carboy before it compacted down to something reasonable. Couple questions; how long after pitching was this pic taken? Did you aerate the wort? Did you let the slurry warm up to room temp before pitching? If it's still good, I'd say it's a good thing you have plenty of headspace...

Last edited:

Last night tasted the port, ice wine, and saison. Topped off the port barrel, apparently the angels are freakin' thirsty! Put the Blonde Ale on 30PSI overnight, looking forward to a fresh one when I get home from work today!

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

Stupid blow off hoses never seem to want to stay nicely submerged underwater where I put them, so I’m exercising my best redneck ingenuity. Turns out the blow off tube fits perfectly down the handle of a water jug. Muahahaha! Problem solved!

Last edited:

I'm gonna try that for my next one....Stupid blow off hoses never seem to want to stay nicely submerged underwater where I put them, so I’m exercising my best redneck ingenuity. Turns out the blow off tube fits perfectly down the handle of a water jug. Muahahaha! Problem solved!

View attachment 700492

After all the cleaning, including racing home to put a few final touches on the bathroom, the notary suggested sitting outside to sign the papers (it's a gorgeous day). Probably a covid thing. Gonna get about 2 grand back from the former mortgage company's escrow account, and I have tacit permission to possibly buy a new SS mash tun....maybe.Not directly for beer, but husband and I just finished flight of the bumblebee cleaning of the house before the notary public comes by tomorrow afternoon for the ritual signing of the refinance papers. Mopped up the sticky spots on the kitchen floor that get tracked in from the brewery, found a missing airlock, and a random growler that I left next to the woodstove to soak out the dried crap in the bottom. Also bought a new heavy-duty mop head for the garage floor to mop up after brewdays. Still looking for that damned keg lube...

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

Looks like you did not use the keg lube for plumbing in the kitchen or bathroom.After all the cleaning, including racing home to put a few final touches on the bathroom, the notary suggested sitting outside to sign the papers (it's a gorgeous day). Probably a covid thing. Gonna get about 2 grand back from the former mortgage company's escrow account, and I have tacit permission to possibly buy a new SS mash tun....maybe.

Nope. That damn tube (which I've been using since I started kegging three years ago) has flown the proverbial coop. Had to use vaseline on the last keg, yes I know it's pretty much the same thing, but that crunched up tube has some memories in it.Looks like you did not use the keg lube for plumbing in the kitchen or bathroom.

Nick&Worty

Well-Known Member

- Joined

- Sep 2, 2020

- Messages

- 282

- Reaction score

- 440

My O2 tank was dead today and I didn’t realize it till pitching time! Today was the first time I’ve had to shake and pray! Hopefully the old truffle shuffle will come through for me!

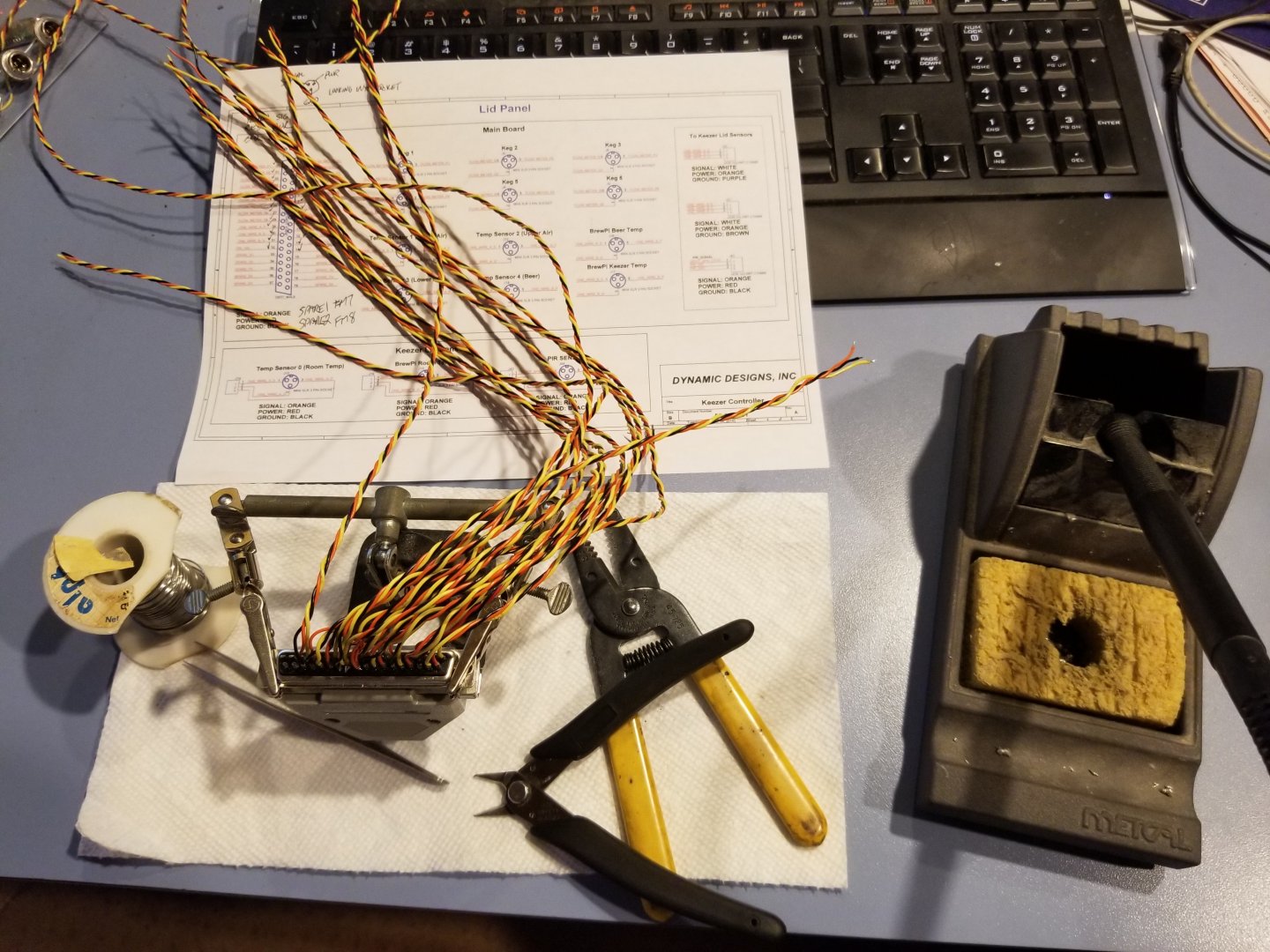

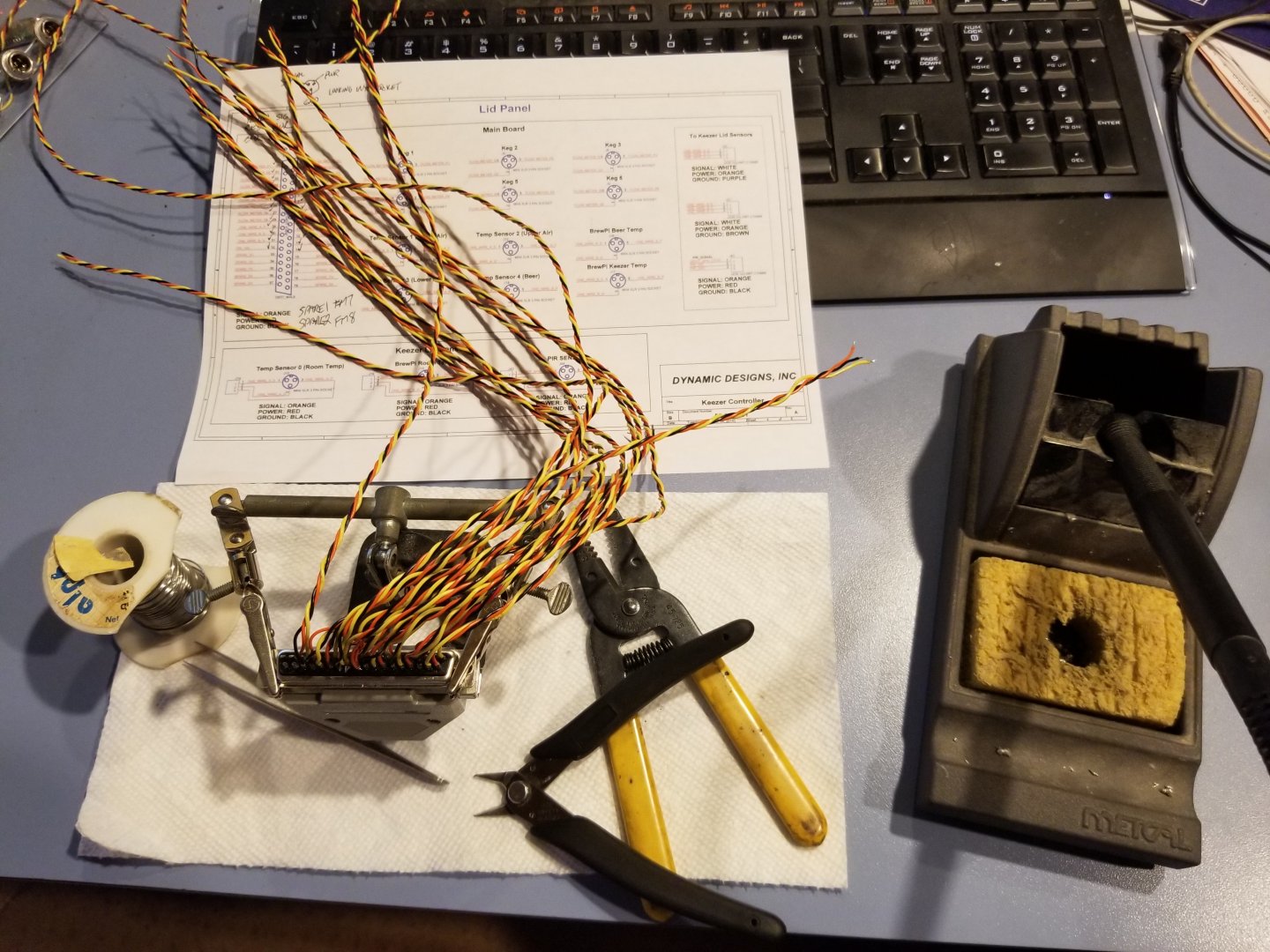

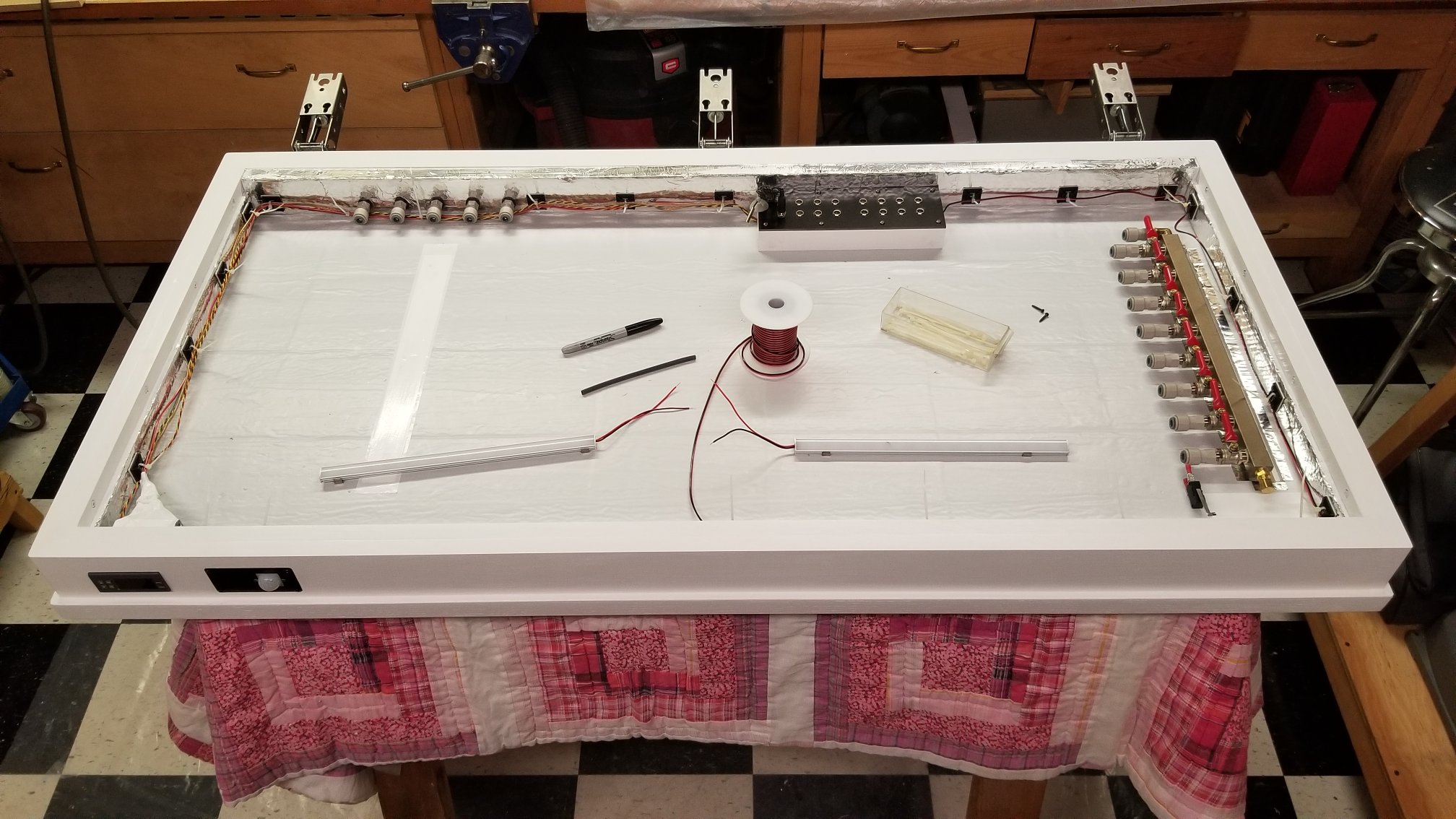

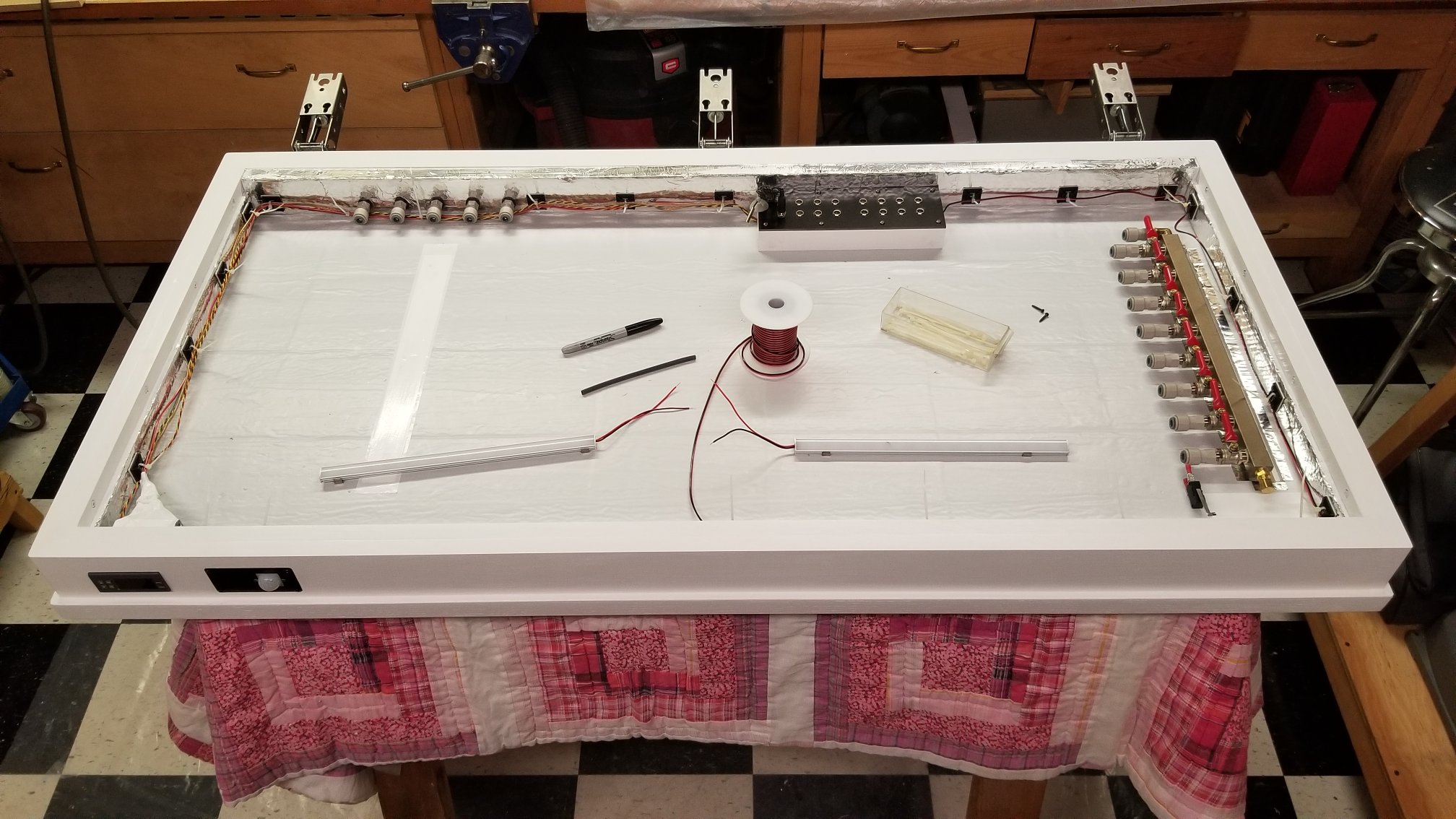

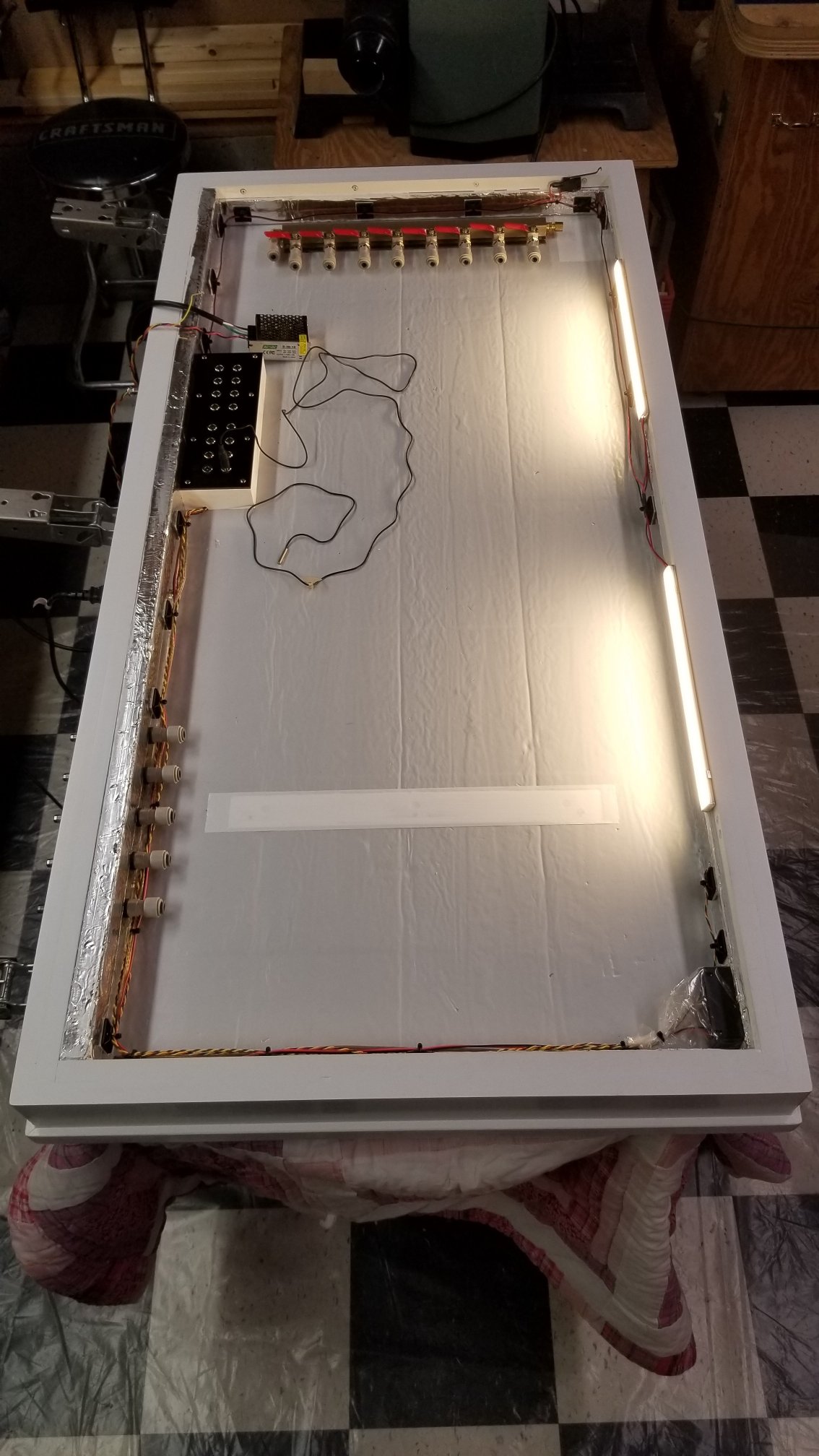

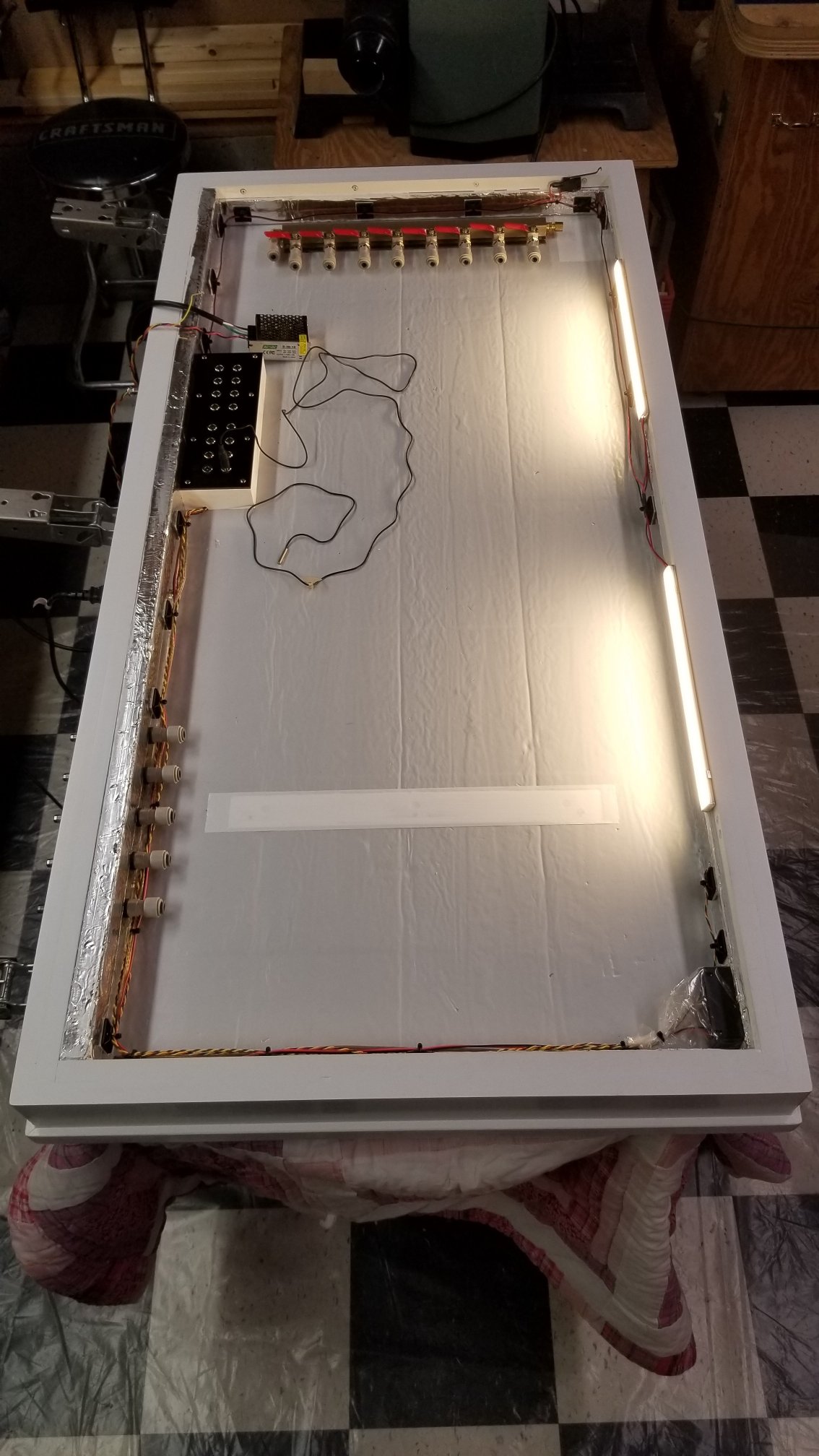

Made some progress today on my keezer build. I finished painting the lid...

...then, because my bag of connectors is still in limbo within the bowels of the USPS in a facility 20 minutes from me - now Day 14 ffs! - I decided to steal connectors from the test panel for my brewery controller. Sucks, but had to be done if I was going to make any headway.

Populated the two panels with the connectors...

...and started building cables.

Lots of stuff still to do but at least there are no blockers now...

Cheers!

...then, because my bag of connectors is still in limbo within the bowels of the USPS in a facility 20 minutes from me - now Day 14 ffs! - I decided to steal connectors from the test panel for my brewery controller. Sucks, but had to be done if I was going to make any headway.

Populated the two panels with the connectors...

...and started building cables.

Lots of stuff still to do but at least there are no blockers now...

Cheers!

Petroleum jelly will prematurely decompose nitrile, neoprene and EPDM O-rings. Make sure to use silicone keg lube.

Joshua Hughes

Well-Known Member

Pretty boring for me. On day 2 of diacetyl rest so just checked temp to make sure it didn’t get too high.

BrewMan13

Whole Nother Level Brewing

Kicked the NEIPA last night, so cleaned the keg and line, and threw the porter on.

I put a few holes in an AZ tea jug cap, one for the tube and some to let gas escape and screw it back on the jug.Stupid blow off hoses never seem to want to stay nicely submerged underwater where I put them, so I’m exercising my best redneck ingenuity. Turns out the blow off tube fits perfectly down the handle of a water jug. Muahahaha! Problem solved!

View attachment 700653

Got some entries ready to ship out.

Bottled some beer for a trade and approved the proof to have my logo professionally screen printed on some pint glasses and finalized the order.

Weeded my hops.

I brewed a CAP and kegged a helles.

I'm not sure why I continue to brew helles. I suppose it's because of the, "If you can brew a helles you can brew anything" thing. I suppose it's a good calibration beer that ensures the brewery is running as it should. It's a nice enough beer and I'll enjoy it, but I'm not sure I agree with the German aphorism--there are much more difficult styles out there.

I'm really looking forward to that CAP, though. I've been running that beer every other month this year, it's really hitting the spot these days.

I'm not sure why I continue to brew helles. I suppose it's because of the, "If you can brew a helles you can brew anything" thing. I suppose it's a good calibration beer that ensures the brewery is running as it should. It's a nice enough beer and I'll enjoy it, but I'm not sure I agree with the German aphorism--there are much more difficult styles out there.

I'm really looking forward to that CAP, though. I've been running that beer every other month this year, it's really hitting the spot these days.

My O2 tank was dead today and I didn’t realize it till pitching time! Today was the first time I’ve had to shake and pray! Hopefully the old truffle shuffle will come through for me!

That sucks!

I'm sure things will work out fine, though. For what it's worth, I learned that it's worth it to keep a working bottle on hand and a full spare. When the working bottle dies, the spare becomes the working bottle and the spare gets replaced. I also like writing the purchase date on each bottle. I managed to kick my Dec. '18 bottle a couple of months ago. It's amazing how long they last!

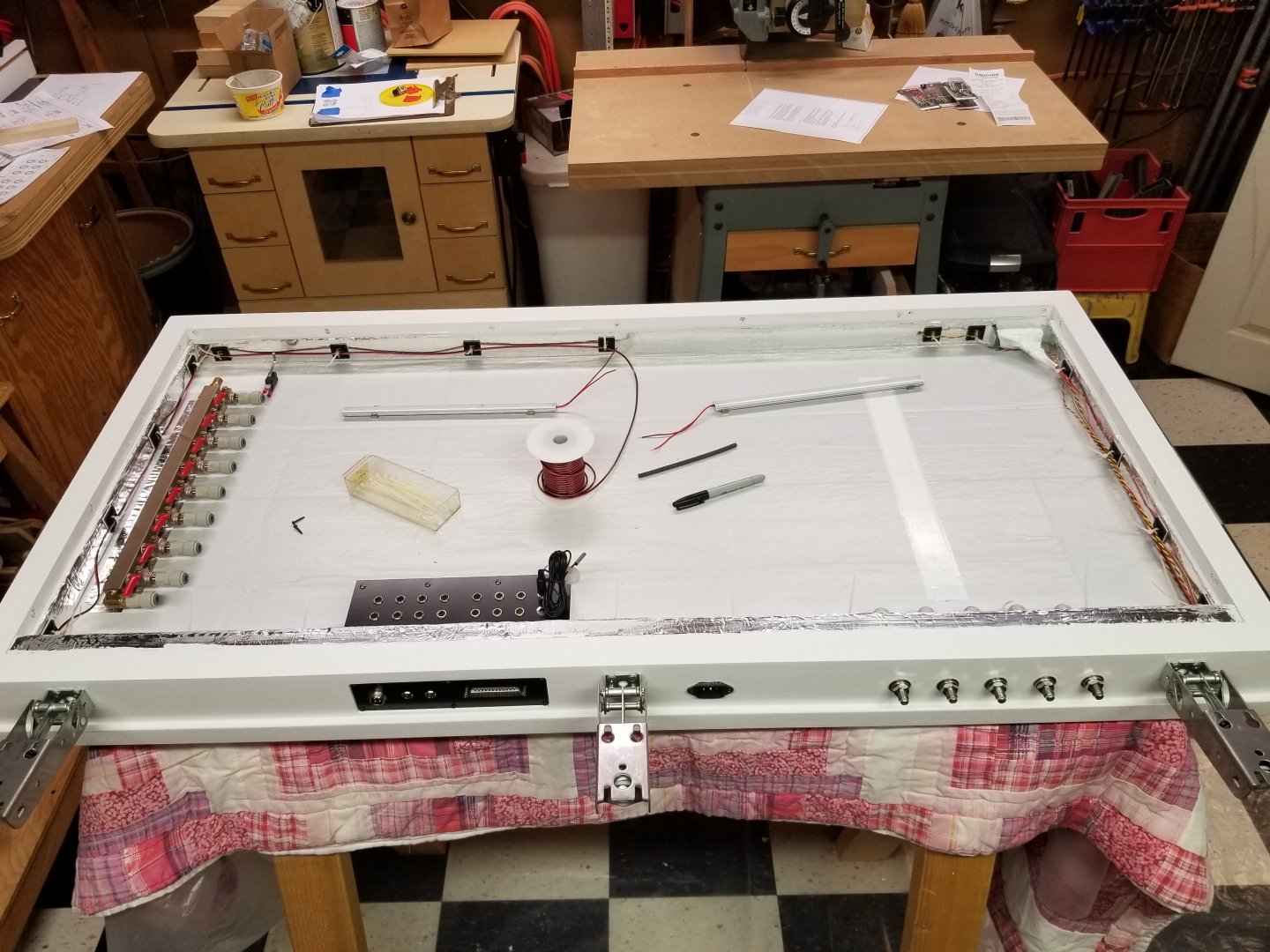

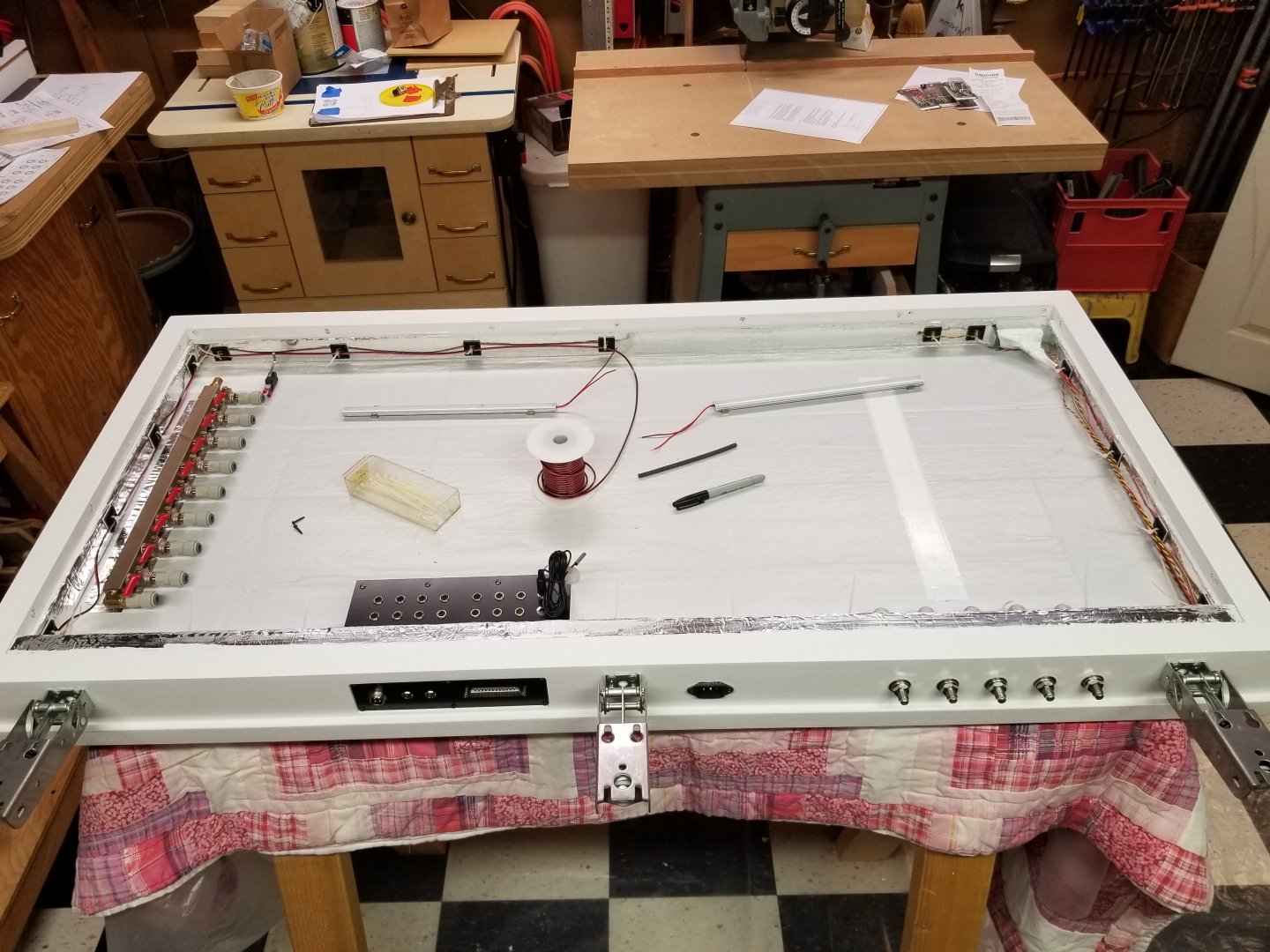

Good progress on "K3" today. Have almost all the wiring done - just need to mount the interior led light bars and the lid switch.

Made a significant ECO to the lid, moving the gas manifold from its original location to the opposite end, more like my current keezer lid. Although I had my reasons for the original location, I had created a big ass mess having it stationed above the edge of the hump, which slammed it against the gas bulkheads. And when I drop in the rinser it'd be Grand Central of tubing. No bueno.

nbd. If that's the worst change I made it's cake. And, ime, no worthy design ever makes it from start to finish without at least one good change

Tomorrow I'll mount the light bars and switch, then hook up my backup controller and test out all of the wiring, making sure all the flow meter runs go to the right places, and same with all the temperature sensor and fan power ports. At that point I'll be ready to pull off The Big Switch, where K2 is decommissioned, and I strip it for the tower, beer lines, drip tray, glass rinser system, and finally the primary brewery controller.

Speaking of K2, I've been steadily drawing it down. Aside from the stout there's about a six pack of beer left in it.

I do have four full kegs plus that stout for when K3 is commissioned, but this is literally the first time in fourteen years I've had one tap empty for more than the time to swap in a freshie, never mind five of them pretty much goners...

Cheers!

Made a significant ECO to the lid, moving the gas manifold from its original location to the opposite end, more like my current keezer lid. Although I had my reasons for the original location, I had created a big ass mess having it stationed above the edge of the hump, which slammed it against the gas bulkheads. And when I drop in the rinser it'd be Grand Central of tubing. No bueno.

nbd. If that's the worst change I made it's cake. And, ime, no worthy design ever makes it from start to finish without at least one good change

Tomorrow I'll mount the light bars and switch, then hook up my backup controller and test out all of the wiring, making sure all the flow meter runs go to the right places, and same with all the temperature sensor and fan power ports. At that point I'll be ready to pull off The Big Switch, where K2 is decommissioned, and I strip it for the tower, beer lines, drip tray, glass rinser system, and finally the primary brewery controller.

Speaking of K2, I've been steadily drawing it down. Aside from the stout there's about a six pack of beer left in it.

I do have four full kegs plus that stout for when K3 is commissioned, but this is literally the first time in fourteen years I've had one tap empty for more than the time to swap in a freshie, never mind five of them pretty much goners...

Cheers!

Happy spring!Weeded my hops.

View attachment 701002

Earlier in the week had a field trip to the Harbor Freight for a bottling table/rolling cart. Today I discovered it works better than I imagined! No drips, no lower back pain, life is good! It's plastic which cleans up easy and it stores kettles and such when I'm not bottling. Today is a good day.

My "Let There Be Light!" moment. After debugging a mis-wired bulkhead power connector (I had to wire everything up-side-down and missed that one) I got the lid switch and cheap LED light bars mounted and working.

Cleaned up the wiring, tie downs and ties, added SS screws to the tie downs to pin them to the wood structure, which also holds all the perimeter foam pieces tightly in place.

All the basic wiring stuff is now checked out, so tomorrow I'll hook up my backup control system to check out the flow meters and temp sensors. Then it'll just be a matter of me pulling the trigger on "K2" to start harvesting the parts I need...

Cheers!

Cleaned up the wiring, tie downs and ties, added SS screws to the tie downs to pin them to the wood structure, which also holds all the perimeter foam pieces tightly in place.

All the basic wiring stuff is now checked out, so tomorrow I'll hook up my backup control system to check out the flow meters and temp sensors. Then it'll just be a matter of me pulling the trigger on "K2" to start harvesting the parts I need...

Cheers!

Labeled some bottles tonight.

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

Picked most of my East Seattle Goldings (~1#) and brewing up a fresh hop ESB right now.

After doing 4-5 fresh hop ales a year (I have N Brewer, Tettnang and ESG plants started from hop bulbs) for the past 4 years, I've settled on the following:

- Base recipe (various bitters or a czech lager)

- use hop pellets for BU/GU ~.8

- split however much fresh hops I have in quarters (1 - 1.5#). To be honest, i just eyeball and toss in handfuls

- add in the quarters at 15, 10, 5 and 0 minutes

- sparge and drain off

- let cool overnight

- decent yeast pitch in the morning

- usually bottle so I can slowly enjoy for a while but also good in the keg

I like the result, it's unique, local terroir, and kinda fun. Northern Brewer does the best for me, and I usually get 2 harvests out of that one. ESG is always latest to mature, small cones and the lowest yield. Tettnang get the least sun just based on trees and the configuration of my front yard.

I also have found that using 2 strings/plant and 1 bine per string seems to work well for my environment and style. I've had 2 or more bines per string, but the usable yield is roughly the same. That said, maybe next year I'll do 3 strings for the N Brewer.

After doing 4-5 fresh hop ales a year (I have N Brewer, Tettnang and ESG plants started from hop bulbs) for the past 4 years, I've settled on the following:

- Base recipe (various bitters or a czech lager)

- use hop pellets for BU/GU ~.8

- split however much fresh hops I have in quarters (1 - 1.5#). To be honest, i just eyeball and toss in handfuls

- add in the quarters at 15, 10, 5 and 0 minutes

- sparge and drain off

- let cool overnight

- decent yeast pitch in the morning

- usually bottle so I can slowly enjoy for a while but also good in the keg

I like the result, it's unique, local terroir, and kinda fun. Northern Brewer does the best for me, and I usually get 2 harvests out of that one. ESG is always latest to mature, small cones and the lowest yield. Tettnang get the least sun just based on trees and the configuration of my front yard.

I also have found that using 2 strings/plant and 1 bine per string seems to work well for my environment and style. I've had 2 or more bines per string, but the usable yield is roughly the same. That said, maybe next year I'll do 3 strings for the N Brewer.

Cleaned the dispenser and flushed the keg to fill with my fest bier for the Oktoberfest party this November with my German buddies. We use to ride our Harley's every Sunday. Jo has a longhorn ranch around Farmersville, Tx.

Bottling day 2.5 gal batch of Wheat Blonde I brewed a couple of weeks ago at the city house. Got 23 12 oz bottles and one 500 ml bottle.

The bottling bucket sample tasted pretty good.

The bottling bucket sample tasted pretty good.

Beautiful brew space! I am thinking that I may need to seal the concrete in my garage sometime in the next few years to make a smoother surface with easier cleanup. I love the peg board for brew tools.Cleaned the dispenser and flushed the keg to fill with my fest bier for the Oktoberfest party this November with my German buddies. We use to ride our Harley's every Sunday. Jo has a longhorn ranch around Farmersville, Tx.View attachment 701202

Today we tasted and stabilized the ice wine, tomorrow we move it for aging.

Moved the Pale Sour to a keg for carbonation and cold crashing. This year we aged it on an oak spiral for 5 months and it completely changed the flavor for the better!

Brewed the West Coast 12 Beers of Christmas Honey-Ginger IPA. Still trying to dial in my process since I upgraded some of my equipment, but I think this is going to be good.

Moved the Pale Sour to a keg for carbonation and cold crashing. This year we aged it on an oak spiral for 5 months and it completely changed the flavor for the better!

Brewed the West Coast 12 Beers of Christmas Honey-Ginger IPA. Still trying to dial in my process since I upgraded some of my equipment, but I think this is going to be good.

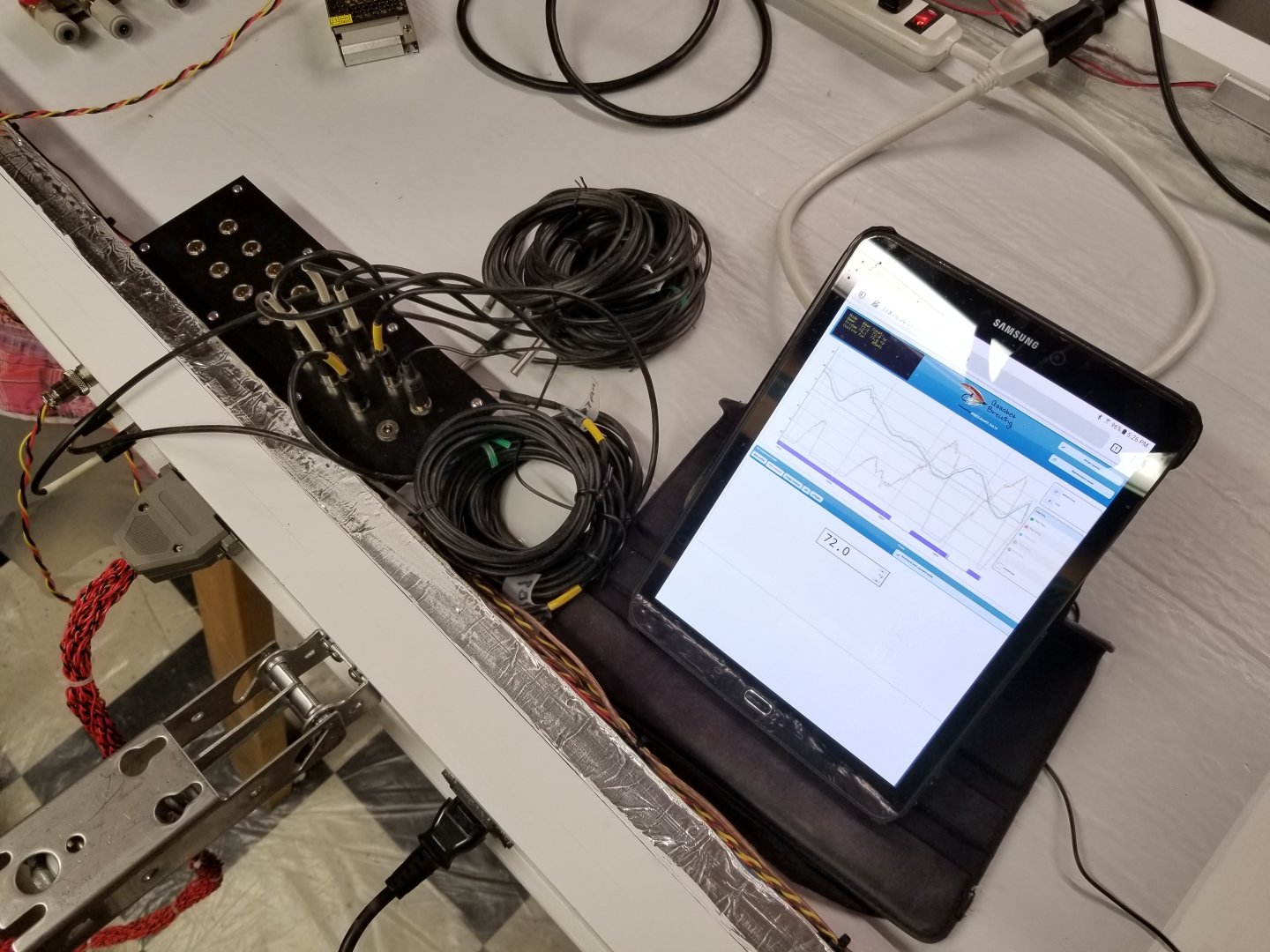

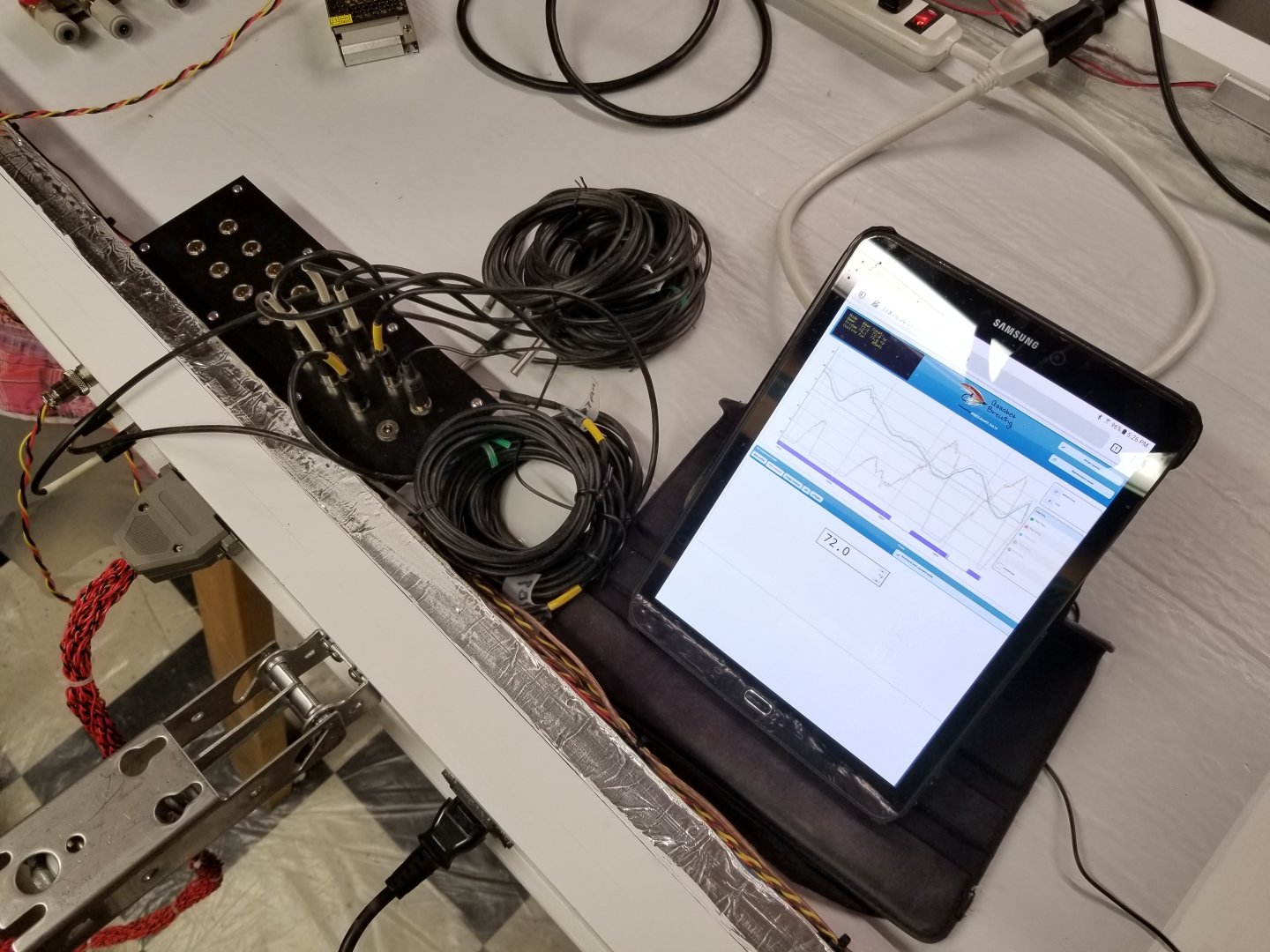

No Patriots game today so I completed the electrical checkout of my "K3" lid project. Started by doing a basic unpowered sanity check using the "known good" umbilical cable (borrowed it from a powered-down K2) to make sure I didn't left-right transpose or "end-around" the DB37 lid connector wiring.

With that out of the way, time to plug everything in and power up the backup controller. No smoke!

Then I pulled up the Raspberry Pints tap list and walked a flow meter through all of the sockets, blowing through it and checking the tap list "poured ounces" count to make sure it incremented at each position...

Next was running my home-rolled temperature logger to check out its five temperature sensors...

Next was running the BrewPi instance that will actually control the keezer compressor, making sure all three of its sensors were registering properly.

Last was making sure the motion detector worked. And with that, the lid is 100% electrically ready to go!

Have to go up to NH tomorrow for a couple of days, hoping to decommission K2 and harvest the parts I need later in the week. Just kicked another keg so there's just the last two with a scant pour or so in each, plus the half-keg of stout that'll go in one of the fridges for hopefully just a little while...

Cheers!

[edit] Before I start blowing big holes through the lid I wanted to see how it looks atop the cabinet. I'm feelin' pretty good right now

Aaand another keg kicked. Down to one...

[edit2] And the last keg just blew a hole in my glass. Nothing holding me back now - literally: exuberance has led me to pick up an integrated drip tray/rinser for a cleaner look - and the option to add one or two single tap towers in the future...

Cheers! (spending my kids' inheritance )

)

With that out of the way, time to plug everything in and power up the backup controller. No smoke!

Then I pulled up the Raspberry Pints tap list and walked a flow meter through all of the sockets, blowing through it and checking the tap list "poured ounces" count to make sure it incremented at each position...

Next was running my home-rolled temperature logger to check out its five temperature sensors...

Next was running the BrewPi instance that will actually control the keezer compressor, making sure all three of its sensors were registering properly.

Last was making sure the motion detector worked. And with that, the lid is 100% electrically ready to go!

Have to go up to NH tomorrow for a couple of days, hoping to decommission K2 and harvest the parts I need later in the week. Just kicked another keg so there's just the last two with a scant pour or so in each, plus the half-keg of stout that'll go in one of the fridges for hopefully just a little while...

Cheers!

[edit] Before I start blowing big holes through the lid I wanted to see how it looks atop the cabinet. I'm feelin' pretty good right now

Aaand another keg kicked. Down to one...

[edit2] And the last keg just blew a hole in my glass. Nothing holding me back now - literally: exuberance has led me to pick up an integrated drip tray/rinser for a cleaner look - and the option to add one or two single tap towers in the future...

Cheers! (spending my kids' inheritance

Last edited:

nursedude

Member

- Joined

- Aug 18, 2012

- Messages

- 16

- Reaction score

- 11

Brown Ale: Bottled 58 12oz bottles and complained the whole time about needing to get a kegerator.

Belgian Quad: Tasted, transferred to secondary, and fined with gelatin. In a few days I guess I'll bottle those as well... It's a vicious cycle!

Belgian Quad: Tasted, transferred to secondary, and fined with gelatin. In a few days I guess I'll bottle those as well... It's a vicious cycle!

Pegboard is cool. If you have the room the more the merrier. I'm a lucky manBeautiful brew space! I am thinking that I may need to seal the concrete in my garasometime in the next few years to make a smoother surface with easier cleanup. I love the peg board for brew tools.

Dry hopped my IPAs last night with Mosaic, Citra, Galaxy and BRU-1. Hopefully I can do a closed transfer to the serving kegs next weekend and place them in the kegerator.

That reminds me, I need to replace my draft lines and clean the faucets this week.

That reminds me, I need to replace my draft lines and clean the faucets this week.

Filtering my Fest bier to carbonate and then transfer to the Paulaner keg for the Oktoberfest party

Getting a few beers labeled for sharing.

All this talk of pegboard inspired me to get some to deal with the container of mess that was previously barely containing my supplies. Felt like crap this morning and took a sick day, and when I was feeling a little better in the afternoon went out to buy some and got this setup in my brewing closet.

Looks greatAll this talk of pegboard inspired me to get some to deal with the container of mess that was previously barely containing my supplies. Felt like crap this morning and took a sick day, and when I was feeling a little better in the afternoon went out to buy some and got this setup in my brewing closet. View attachment 701419

- Joined

- Dec 21, 2012

- Messages

- 355

- Reaction score

- 473

Hm. I may have to steal this.All this talk of pegboard inspired me to get some to deal with the container of mess that was previously barely containing my supplies. Felt like crap this morning and took a sick day, and when I was feeling a little better in the afternoon went out to buy some and got this setup in my brewing closet.

Bought more ice for my chiller for the fermenter. Okay, now I am seriously considering a glycol system, the continuous buying of ice is seriously cutting into my cost savings of making my own beer!

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K