Brewer_Dad

Well-Known Member

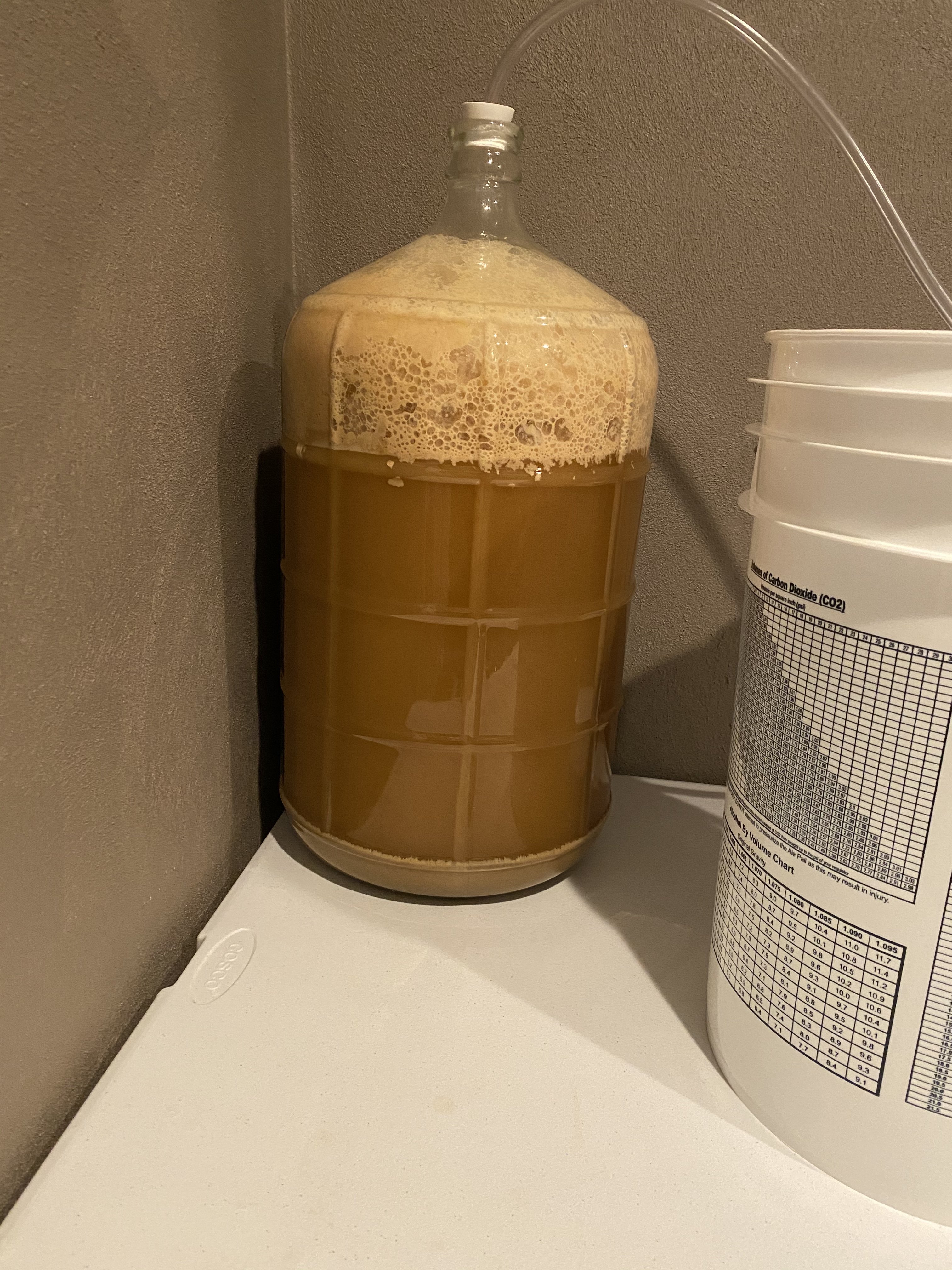

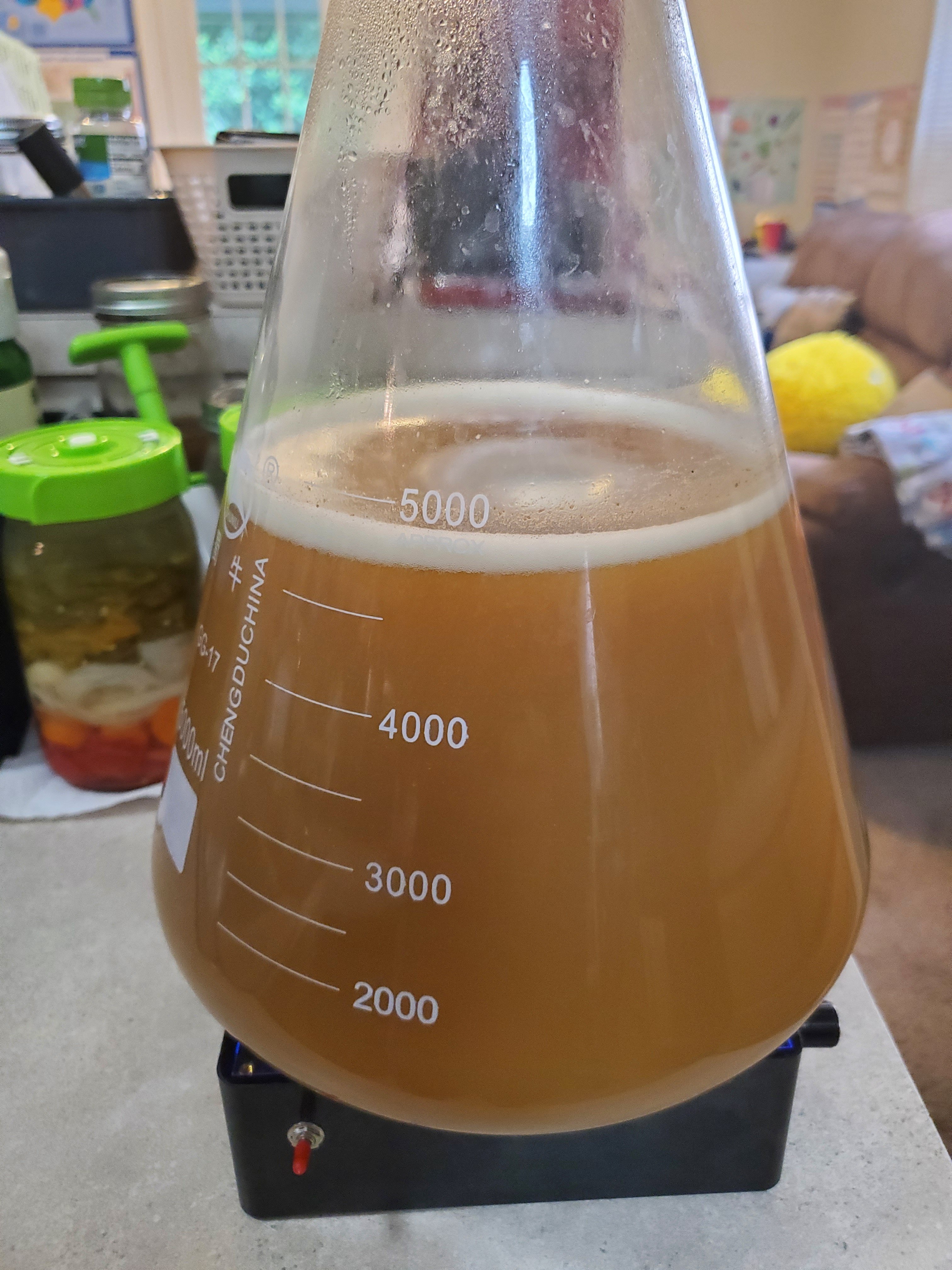

I did 2 batches, 5 gallons each. An American IPA and a hoppy golden ale - I'm exhausted.

Reason I did this is that I wanted to take advantage of the current temperature of the room I use to ferment (has been steady 19C), since spring just started and temps will start to rise. Also I'm starting my shifts next week, I work 4 days of 3 days off at a mine site, so it gives me plenty of time to let it cold crashing while I'm away.

Reason I did this is that I wanted to take advantage of the current temperature of the room I use to ferment (has been steady 19C), since spring just started and temps will start to rise. Also I'm starting my shifts next week, I work 4 days of 3 days off at a mine site, so it gives me plenty of time to let it cold crashing while I'm away.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)