You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

Got this picture from my ex Army buddy who is now a Lt. on Seattle PD. Things are rough up there. Said he asked for a sign from above. Well if this ain't a blessing from on high to drink beer I don't know what is!

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

Like I said! Tried and trusted!!!I made a Helles today and thankfully returned to the loving embrace of 34/70 after my disastrous dalliance with Diamond Lager.

Should have posted yesterday, but I have been doing double shifts lately, so, thanks to @mcl for the plate chiller. I look forward to chilling my wort faster and making better beer.

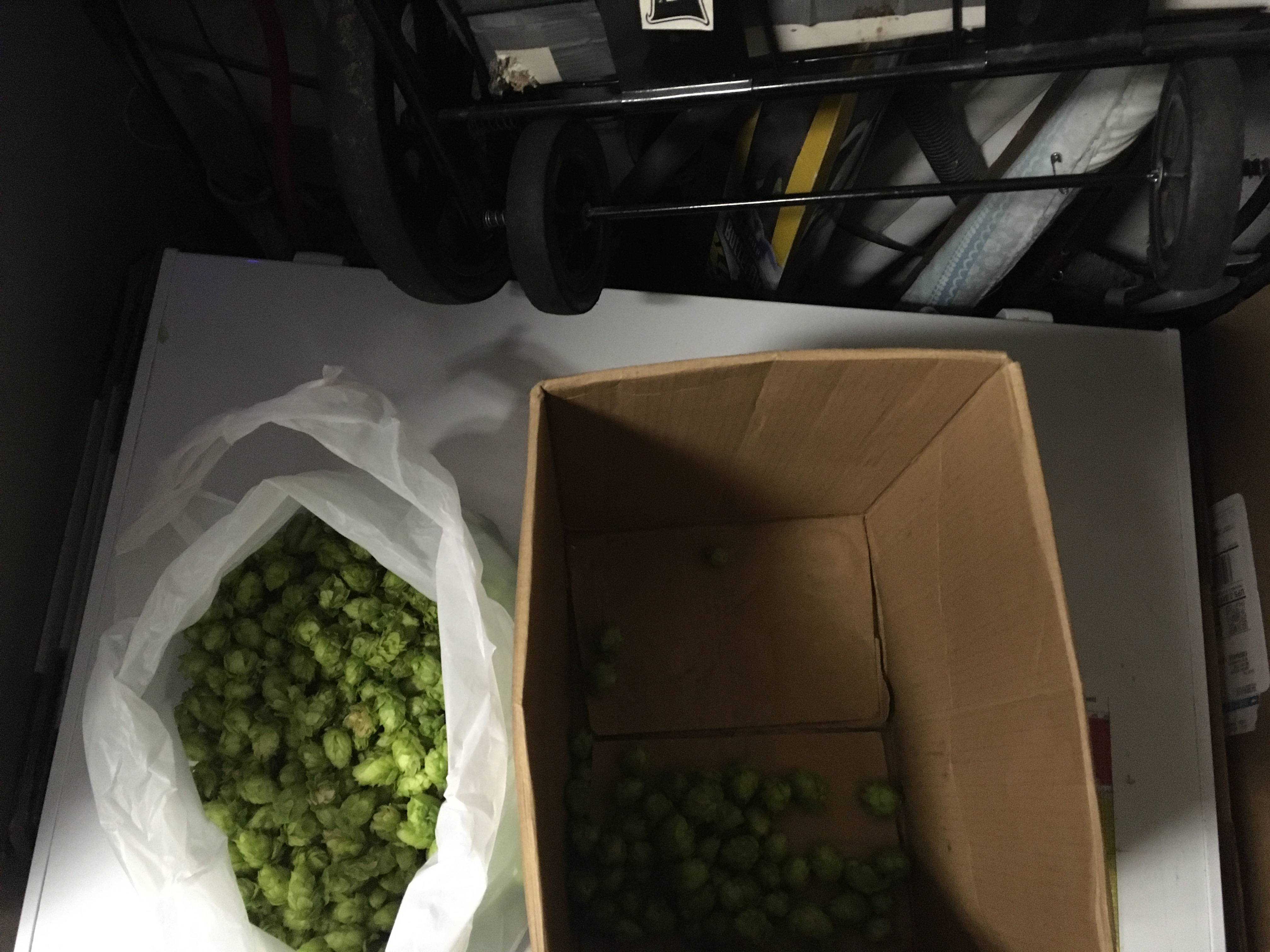

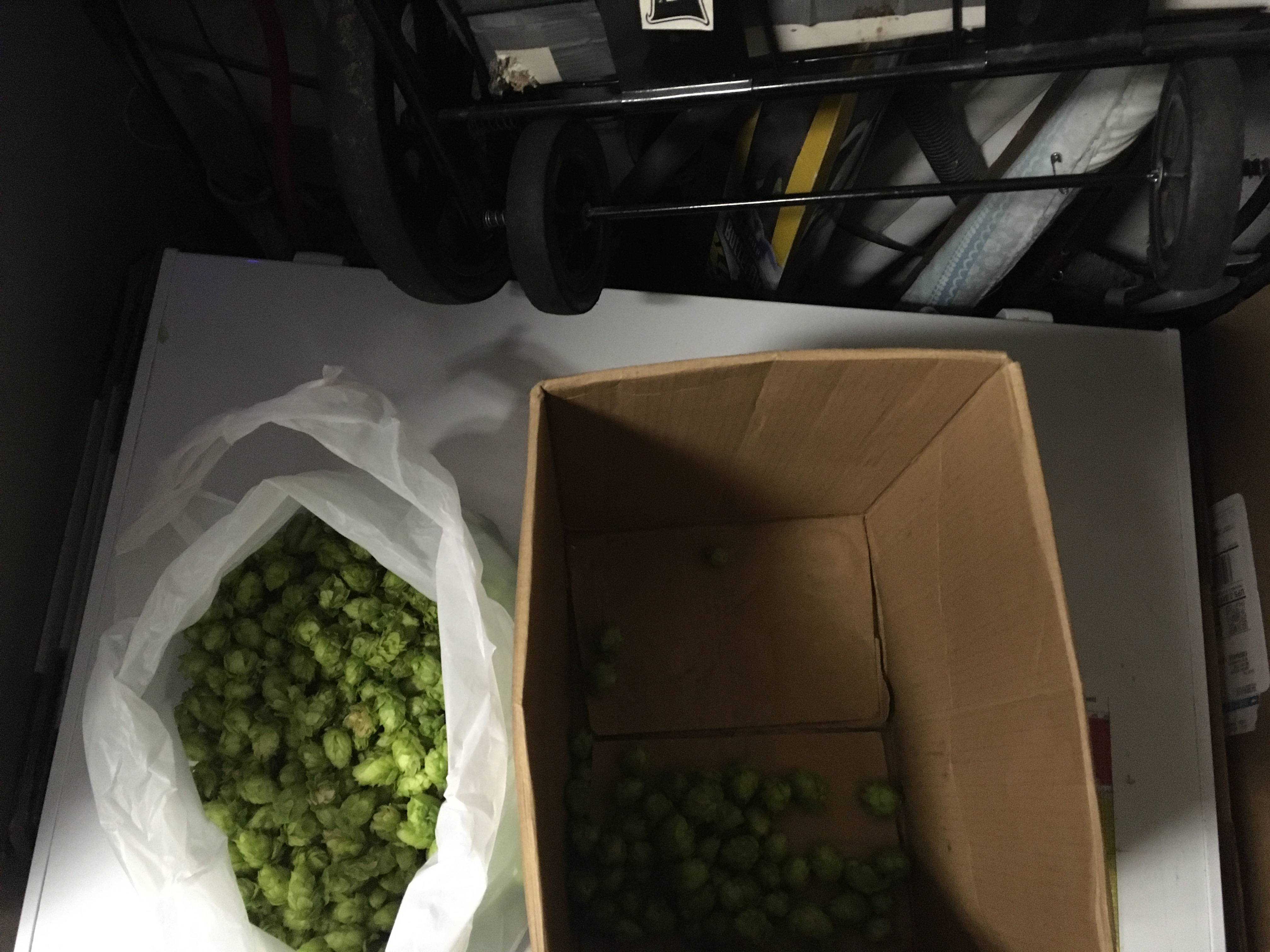

Now for a hop-growers question: Some of my hops are falling off the bine. They are soft and springy, not dry at all and not very aromatic. This is the first year that I have strung my hops up to the roof (2nd story), so, is this just wind taking its toll? Is there anything else that would knock healthy hops off the bine?

Now for a hop-growers question: Some of my hops are falling off the bine. They are soft and springy, not dry at all and not very aromatic. This is the first year that I have strung my hops up to the roof (2nd story), so, is this just wind taking its toll? Is there anything else that would knock healthy hops off the bine?

I grew Chinook, Cascade, Centennial and some Fuggles for seven years and do not recall cones randomly falling off bines - at least prior to harvest time, when they were actually a pita to pop free. It's one of the reasons I finally gave it up

Cheers!

Cheers!

Today's progress...cut the 3/4" plywood top for the lid, always an adventure in my wee workspace. This was the next to last cut - I should have shot a pic of the first cuts on the full sheet but I'd have had to crawl under stuff to get to the doorway.

Fits nicely...

Laid out vertical lines from the oem lid mounting screw holes. For some reason the groups of four screw holes are not vertically aligned.

I did a rubbing to pick up the offsets. Weird - no idea why they did that, but I have to deal with it.

The oem lid gasket is a full 1/2" tall. I actually bought a replacement gasket, but it uses a back-side attaching rib with an extreme arrow-head profile that would be very tough to accommodate, so I'll be sending it back and using a more conventional, foam rubber gasket. But that will compress in the 1/8-3/16" ball park, so I can't mount the hinges to the lid using the same geometry as the original lid. My mount points have to be around 3/8" higher up on the lid edge.

There isn't a lot of adjustability in the hinge elevation relative to the cabinet - maybe a 1/4" - so I need to get the mounting right. Too low and the lid won't seal, too high and the lid won't full close. I finally decided to make a mechanical mock-up to give me something to visualize while not screwing up the actual lid.

[Aside: Looking at that angle there's a small chance that once my tower is attached the lid will balance in the raised position.

Otherwise I'm looking at deployable prop arms.]

This is with the hinge mount points 1/2" higher than the oem lid. I think it will work.

That was with the hinges bottomed on the cabinet ends; the only adjustability would be up.

I stuck the end of the prospective gasket material under the back edge. It's almost totally compressed - adjusting the hinges up an 1/8" would be a perfect "crush".

Tomorrow I'll summon up the courage to drill the lid frame for the hinges and hopefully all will be well there. Next I'll take the lid apart, drill pocket holes around the perimeter to attach the top to the frame, dry fit the frame to the lid and do some prep sanding before finally gluing and screwing it all together for the last time...

Cheers!

Fits nicely...

Laid out vertical lines from the oem lid mounting screw holes. For some reason the groups of four screw holes are not vertically aligned.

I did a rubbing to pick up the offsets. Weird - no idea why they did that, but I have to deal with it.

The oem lid gasket is a full 1/2" tall. I actually bought a replacement gasket, but it uses a back-side attaching rib with an extreme arrow-head profile that would be very tough to accommodate, so I'll be sending it back and using a more conventional, foam rubber gasket. But that will compress in the 1/8-3/16" ball park, so I can't mount the hinges to the lid using the same geometry as the original lid. My mount points have to be around 3/8" higher up on the lid edge.

There isn't a lot of adjustability in the hinge elevation relative to the cabinet - maybe a 1/4" - so I need to get the mounting right. Too low and the lid won't seal, too high and the lid won't full close. I finally decided to make a mechanical mock-up to give me something to visualize while not screwing up the actual lid.

[Aside: Looking at that angle there's a small chance that once my tower is attached the lid will balance in the raised position.

Otherwise I'm looking at deployable prop arms.]

This is with the hinge mount points 1/2" higher than the oem lid. I think it will work.

That was with the hinges bottomed on the cabinet ends; the only adjustability would be up.

I stuck the end of the prospective gasket material under the back edge. It's almost totally compressed - adjusting the hinges up an 1/8" would be a perfect "crush".

Tomorrow I'll summon up the courage to drill the lid frame for the hinges and hopefully all will be well there. Next I'll take the lid apart, drill pocket holes around the perimeter to attach the top to the frame, dry fit the frame to the lid and do some prep sanding before finally gluing and screwing it all together for the last time...

Cheers!

Last edited:

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

I was proud of the keezer that my 9 year old son and I put together. I am realizing, though, that we assembled a Volkswagen Beetle. You, sir, are building a Ferrari.

Well...I appreciate the kind words, but just to prevent end game disappointment, it'll likely all end up in "Appliance White", like K1 and K2.

Being this is the third keezer build in 14 years I'm disinclined to get more invested than that

Cheers!

Being this is the third keezer build in 14 years I'm disinclined to get more invested than that

Cheers!

All I’m saying is that mine in comparison looks like it’s held together with bondo, chewing gum, and chicken wire; yours has some actual engineering and sexy, hand-crafted fenders.Well...I appreciate the kind words, but just to prevent end game disappointment, it'll likely all end up in "Appliance White", like K1 and K2.

Being this is the third keezer build in 14 years I'm disinclined to get more invested than that

Cheers!

Replaced all my silicone hoses today in my brewery. Also got rid of my worm clamps and used Oeitiker clamps on all my tri clamp connections for a nice clean install. Looking good for brew day on Saturday!

John

John

For some reason that brought back memories of "Fernando Lamas"

I fed my 4th generation Ardennes 3522 Belgian yeast culture. (Maybe last iteration.)

The yeasties are getting restless — Time to Brew!

Next up, Idaho Gem (9.1%AA)/Vienna Malt SMaSH. Should be awesome with fruity Belgian yeast.

Any suggestions for hop addition schedule? I want to be below 35 IBU’s at 1.055 O.G.

The yeasties are getting restless — Time to Brew!

Next up, Idaho Gem (9.1%AA)/Vienna Malt SMaSH. Should be awesome with fruity Belgian yeast.

Any suggestions for hop addition schedule? I want to be below 35 IBU’s at 1.055 O.G.

Cleaned kegs and kegged cider.

Huge day today!

The whole hinging thing had me tied up in self-doubt. Honest to god if you'd seen me today you'd think I seriously needed leveling meds. I must've laid out 10 full sets of lines, sanding each off in favor of the next, before I finally settled on a drill pattern and went to town on the doubled back stretchers on the press [sorry 'bout the fried pic]...

Ok, so that cake was baked and whatever was going to happen when the lid was attached to the cabinet was going to happen. But next I had to drill a crapton of pocket holes in the lid framing - and almost every step of the way I kept thinking I had the pieces either upside down or I was drilling the wrong side. Even the last board freaked me out because looking at it made me think I'd drilled the other 4 pieces wrong. I actually broke a bit of a panic sweat at that point.

BUT...somehow I managed not to doubt myself into an actual eff-up, and got the lid assembly glued and screwed together.

So, on to the real drama: did I get the hinge mounting right or did I do something I was gonna have to fix?

Nailed it!

And the next bestest everest part: it stands up on its own!

So...tomorrow I'll sand that puppy up nice, hit it with primer, and maybe get one coat of paint on it (or not, if past is prologue, in which case I'll do both coats on Sunday). Next will be fitting the insulation board, then starting to mount the gas hardware...

Cheers!

The whole hinging thing had me tied up in self-doubt. Honest to god if you'd seen me today you'd think I seriously needed leveling meds. I must've laid out 10 full sets of lines, sanding each off in favor of the next, before I finally settled on a drill pattern and went to town on the doubled back stretchers on the press [sorry 'bout the fried pic]...

Ok, so that cake was baked and whatever was going to happen when the lid was attached to the cabinet was going to happen. But next I had to drill a crapton of pocket holes in the lid framing - and almost every step of the way I kept thinking I had the pieces either upside down or I was drilling the wrong side. Even the last board freaked me out because looking at it made me think I'd drilled the other 4 pieces wrong. I actually broke a bit of a panic sweat at that point.

BUT...somehow I managed not to doubt myself into an actual eff-up, and got the lid assembly glued and screwed together.

So, on to the real drama: did I get the hinge mounting right or did I do something I was gonna have to fix?

Nailed it!

And the next bestest everest part: it stands up on its own!

So...tomorrow I'll sand that puppy up nice, hit it with primer, and maybe get one coat of paint on it (or not, if past is prologue, in which case I'll do both coats on Sunday). Next will be fitting the insulation board, then starting to mount the gas hardware...

Cheers!

Last edited:

SteveH aka shetc

Well-Known Member

- Joined

- Jul 28, 2013

- Messages

- 3,151

- Reaction score

- 5,675

Used jaggery for the sugar addition to a saison.

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

Never heard of that? Looks like a Mexican chocolate pudding mode!Used jaggery for the sugar addition to a saison. View attachment 699124

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

JA just think of all the people who don't have a "car" at all! Be proud of your "Volkswagen"! Might not be pretty but long as it gets you there!!All I’m saying is that mine in comparison looks like it’s held together with bondo, chewing gum, and chicken wire; yours has some actual engineering and sexy, hand-crafted fenders.

Hit the LHBS for a 55# bag of Maris Otter and the parts to make the new (used) plate chiller fully interactive. Figured that I won't be filtering/aerating my beer like I used to (post-chill, as it goes into fermenter), so also picked up the bits I needed to infuse O2 into the wort pre-pitch. Hit the hardware store for propane and an O2 tank. Harvested 9oz of Shaddock for tomorrow's saison. Next on the to-do list: finish the prep for the saison (filter H2O & grind grain, maybe I should do an overnight mash...hmmm), check on the Centennial (harvest some for bittering the saison), chaptalize the ice wine, keg the Blonde ale, and if I have the energy, bottle some of the sours.

If this seems like a lot, it's because I'd really like to be able to watch football tomorrow-Dad's a Steelers fan.

Edit: Got 1oz of fresh Centennial. Didn't cut the bines down, hoping the sidearms will keep producing.

I think what this means is I have approximately 1.8oz dried Shaddock and .2oz dried Centennial (for bittering/flavor comparison) and I already dried out .2oz of Old Mission that ripened earlier. So a home-grown, wet-hop saison.

If this seems like a lot, it's because I'd really like to be able to watch football tomorrow-Dad's a Steelers fan.

Edit: Got 1oz of fresh Centennial. Didn't cut the bines down, hoping the sidearms will keep producing.

I think what this means is I have approximately 1.8oz dried Shaddock and .2oz dried Centennial (for bittering/flavor comparison) and I already dried out .2oz of Old Mission that ripened earlier. So a home-grown, wet-hop saison.

Last edited:

I braved the revenue-seeking constabulary of Northern Virginia to acquire a sack of Maris Otter. Good beer is worth taking insane risks such as this.

As someone else from the great PNW, that blue sky (not to mention the cloud bottle) is something we've been hoping for the last few weeks. Finally got some rain the last couple days to finally wash all the smoke out of the air from the wildfires in OR & WA that's been plaguing us. Where I live (about 30 miles south of Seattle, in the beginning of the Cascade foothills) we've had random fires in the trees and nothing but smoke for 2 weeks. Today was the first day I could actually breathe without sneezing. Ran into a monster rainstorm coming home from the LHBS and laughed like a loon. Good day.Got this picture from my ex Army buddy who is now a Lt. on Seattle PD. Things are rough up there. Said he asked for a sign from above. Well if this ain't a blessing from on high to drink beer I don't know what is! View attachment 698857

Shopping! Ran slap out of grain on the last brew, and since we refinanced the house and have a couple of free paychecks, I restocked the grain bins, bought some yeast, exchanged TWO propane tanks, and bought a new out-hose for the plate chiller; old one is a cheapie from wallyworld that has more kinks than an Amsterdam cathouse. Planning a dryer version of the House lager tomorrow; adding a pound of table sugar to take it down below 1.010. Still deeply enamored with Sterling for bittering, and Hallertau Blanc and Mittelfruh late; makes for a nice refreshing lager with some floral flavor/aroma notes. LHBS is having one hell of a time getting yeast, so going with S-189 for this one. I usually do my lagers warm, this one will ferment at 60 since (according to google) this yeast seems to do fairly well there.

Joshua Hughes

Well-Known Member

Odd I just seen this. I brewed a Dunkel with 34/70 last night so we’ll see. I’m keeping temp between 50-55 that sound good? The Helles I had last night was from the Diamond and I quite enjoy it BUT it is only the second lager ive brewed and both were from a packet of Diamond this Helles a slurry from a dunkelIf you look at page 7043 of the What Are You Drinking Now thread, you'll see a more detailed post outlining my struggles with Diamond. Bear in mind that my lager recipes are established and have a reliable track record with 34/70. Working on the assumption that Diamond is just a more reasonably priced version of 34/70, I treated it as such. Unfortunately, it didn't seem to perform that way on the series of beers that I brewed with Diamond.

In short: 1) At identical pitching rates, Diamond was very sluggish below 55F. In fact, it didn't do much of anything until I raised it to 55F. 2) It posted noticeably and consistently lower attenuation rates than 34/70, even when I strongly encouraged it to consume the last few points by raising it into the mid-60s, then left it for an extended D-rest at 70F. On the plus side, when it's done, it's done and it flocs hard. 3) The beers produced by Diamond aren't terribly crisp and they drink more like a mock lager (Pacman strain at 55F sorta thing). Diamond produces a beautiful roundness and softness that I think would be exceptional in a cream ale or American wheat, but that's not what I want in a lager--and that's not what 34/70 does.

My experience with Diamond seems to be way, way outside the norm. So much so, in fact, that I'm starting to wonder if my packages may have been mis-labeled, or perhaps one of the sachets that I pitched was mis-picked, I was too stupid to notice the error, and I inadvertently pitched a hybrid strain of Diamond and a packet of something else. My results are so far outside the norm that something bizarre like that must've happened.

SteveH aka shetc

Well-Known Member

- Joined

- Jul 28, 2013

- Messages

- 3,151

- Reaction score

- 5,675

Never heard of that? Looks like a Mexican chocolate pudding mode!

Indian version of unprocessed sugar, made from cane, dates, and palm sap. There are also Central and South American versions.

Brewed a saison while at a club brew, a lot of fun.

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

I braved the revenue-seeking constabulary of Northern Virginia to acquire a sack of Maris Otter. Good beer is worth taking insane risks such as this.

Odd I just seen this. I brewed a Dunkel with 34/70 last night so we’ll see. I’m keeping temp between 50-55 that sound good? The Helles I had last night was from the Diamond and I quite enjoy it BUT it is only the second lager ive brewed and both were from a packet of Diamond this Helles a slurry from a dunkel

It's going to be great, sir!

You can't do wrong with 34/70 at 50-55F. I pitched last Saturday's Helles at 45F and ran it at 50F for the rest of the week, tonight it's at 1.011 from an OG of 1.049. I suppose I could keg it tomorrow and let it D-rest and finish up in the keg, but I tend to let lagers sit on the yeast for three weeks.

I'm encouraged by your remarks about Diamond as it lends credence to my notion that something bizarre happened to my packets. I didn't just try Diamond, I bought a dozen packets, so I'll be running another series of beers with Diamond some time next year. Hopefully, my results will converge with your own.

I'm not kidding, sir, they are shameless and they are greedy over there!

BrewMan13

Whole Nother Level Brewing

Kegged my gruit inspired stout. Needs time for the flavors to meld, but no worries as i have plenty of other stuff in the mean time

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)