- Joined

- Nov 26, 2013

- Messages

- 9,918

- Reaction score

- 24,072

shop is barely 15 x 12

Luckily a small batch, but yeah, not happy.Ouch.

"LUXURY!"

All "Four Yorkshiremen" aside, that is nice setup. My shop area is longer but more narrow and all operations must be painfully planned out in advance.

(not a great shot of the shop)

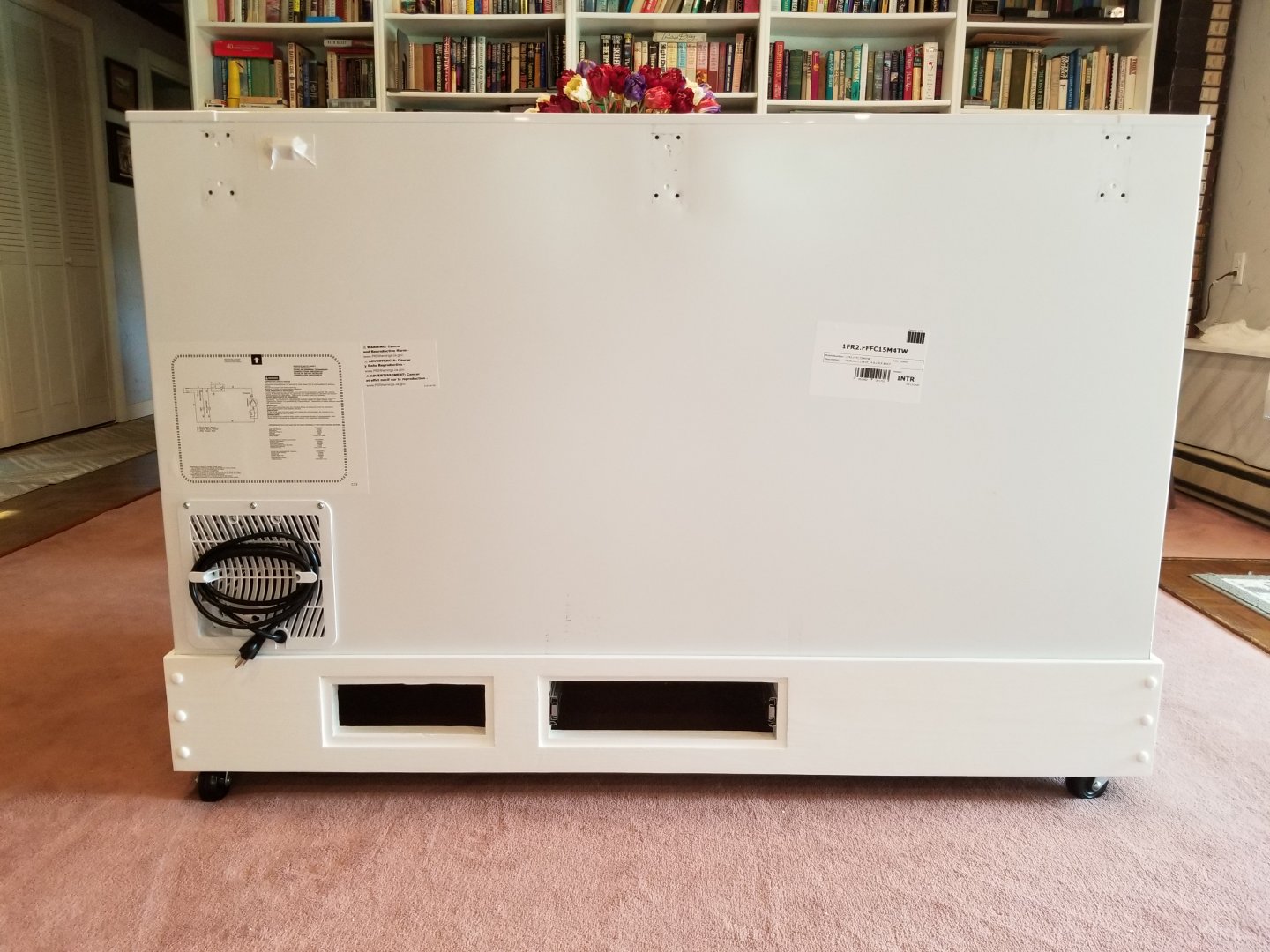

View attachment 697757

All good Hoppy. I transferred what was supposed to be my British Golden but color suggest more a British Brown...Its got English malt, English hops so I'll just be hoppy..ah, I mean happy....to settle on English style type beer....ale....as long as it's drinkable!Went to bottle a dunkels weissbier, but discovered a pellical.Soooo, Dopplebock was bottled.

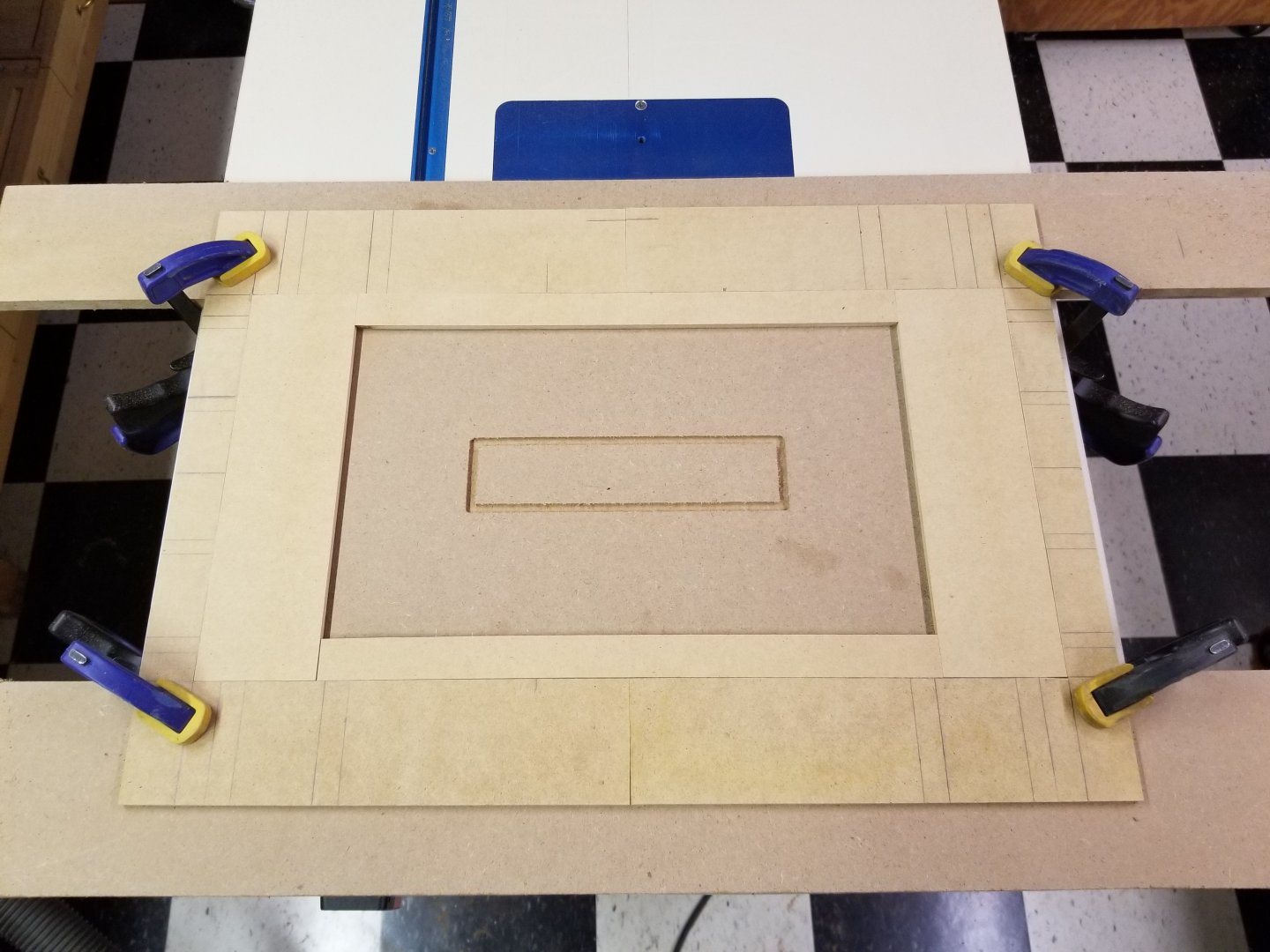

View attachment 697483

just looking at that second shot, I feel like I could be in a local hardware store...yeesh!!

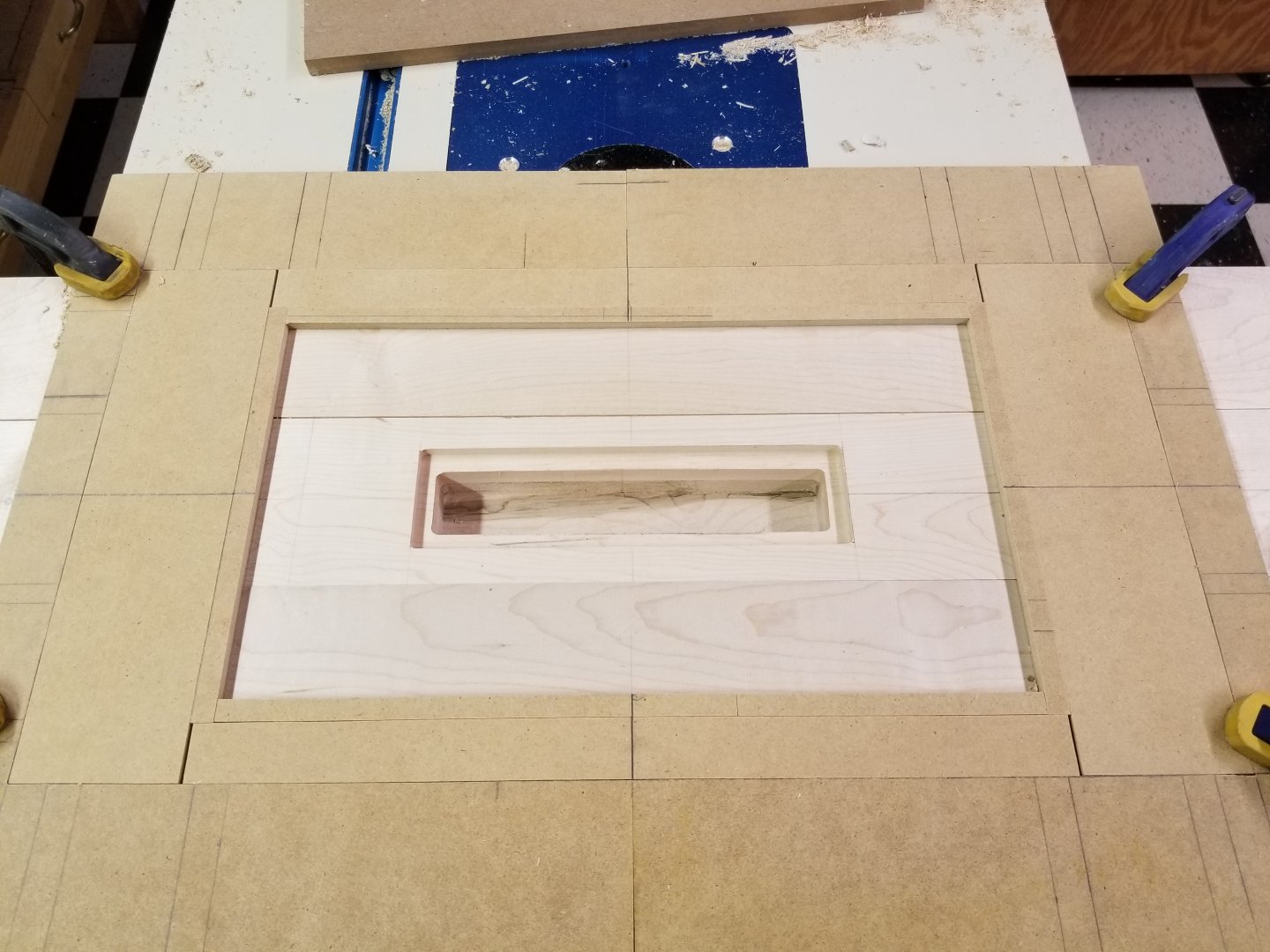

[T]hen spent the afternoon sanding, filling and priming.

I wasn't going to get both top coats done today anyway, but I can tomorrow, so it's a wash.

My first 3 lagers I used Diamond Since it’s what was in stock. What didn’t you like about it? Any comparisons? i have 34/70 for the next few. I have onlt been able to drink the first of those lagers and really liked it. The second is ready to drink Tuesday and Third was just bottledI made a Helles today and thankfully returned to the loving embrace of 34/70 after my disastrous dalliance with Diamond Lager.

My first 3 lagers I used Diamond Since it’s what was in stock. What didn’t you like about it? Any comparisons? i have 34/70 for the next few. I have onlt been able to drink the first of those lagers and really liked it. The second is ready to drink Tuesday and Third was just bottled

Stick with 34/70! Tried and trustedIf you look at page 7043 of the What Are You Drinking Now thread, you'll see a more detailed post outlining my struggles with Diamond. Bear in mind that my lager recipes are established and have a reliable track record with 34/70. Working on the assumption that Diamond is just a more reasonably priced version of 34/70, I treated it as such. Unfortunately, it didn't seem to perform that way on the series of beers that I brewed with Diamond.

In short: 1) At identical pitching rates, Diamond was very sluggish below 55F. In fact, it didn't do much of anything until I raised it to 55F. 2) It posted noticeably and consistently lower attenuation rates than 34/70, even when I strongly encouraged it to consume the last few points by raising it into the mid-60s, then left it for an extended D-rest at 70F. On the plus side, when it's done, it's done and it flocs hard. 3) The beers produced by Diamond aren't terribly crisp and they drink more like a mock lager (Pacman strain at 55F sorta thing). Diamond produces a beautiful roundness and softness that I think would be exceptional in a cream ale or American wheat, but that's not what I want in a lager--and that's not what 34/70 does.

My experience with Diamond seems to be way, way outside the norm. So much so, in fact, that I'm starting to wonder if my packages may have been mis-labeled, or perhaps one of the sachets that I pitched was mis-picked, I was too stupid to notice the error, and I inadvertently pitched a hybrid strain of Diamond and a packet of something else. My results are so far outside the norm that something bizarre like that must've happened.

What's your high level process for fresh hop batches? I have two Northern Brewer fresh hop ales going to try out #1. 1) boiled with pellets for an BU/GU ratio of about 60%, then dumped in 1.5 pounds of fresh hops at flame out and let cool naturally, and 2) BU/GU ratio with pellets to ~60% then fresh hops 1/4# at 15, 10, 5 and 0 minutes and chilled. Both in fermenters now.Picked my 2020 hops and put a West coast medley of 2019 hops in a Randallizer with a Blonde Ale.