You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Do you use a spunding valve of some kind or are you managing pressures manually?

I’ve thought about doing an open fermentation, but always chicken out.

This is that same keg today. It's ready to dial back.

What did I do today? Nada... Really.

Just looked at the valve and poured a beer. - Pecan Smoked Alt.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I do something like what you do on the oven cycle. It depends what I want on lovibond. I have a time and temp chart that i use.OMG I never thought of using the instant pot. I just soak it overnight, then cook for 2 hours in the oven at 160. Then spread it out to dry for another hour or so at 200, once it's dry I crank the oven up to 300 and roast until it looks right. Do you soak the grain before adding to the instant pot? Please share!

I start with 2lbs of pale malt. Measure out distilled water by weight equal to grain weight, less 5% (29oz). Soak it with distilled water for 24 hours refrigerated. Then into the instant pot for 8 hours at 152F. Then I throw it into the oven, in baskets to dry, no heat, only using the oven light on to dry low temp. The oven uses an incandescent light bulb. The temp is roughly 145F with door completely closed. I use a remote meat probe inserted into the grain.

This drying/curing is to keep the diastatic power intact when I make lower 10L-60L Crystal Malt. I still do the same even with 90L - 120L. As you know it requires high temps.

FYI - Heating grains over 210F with greater than 10% moisture hurts the diastatic power.

Screen baskets for drying/curing are shown below with instant pot insert beside them.

Last edited:

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

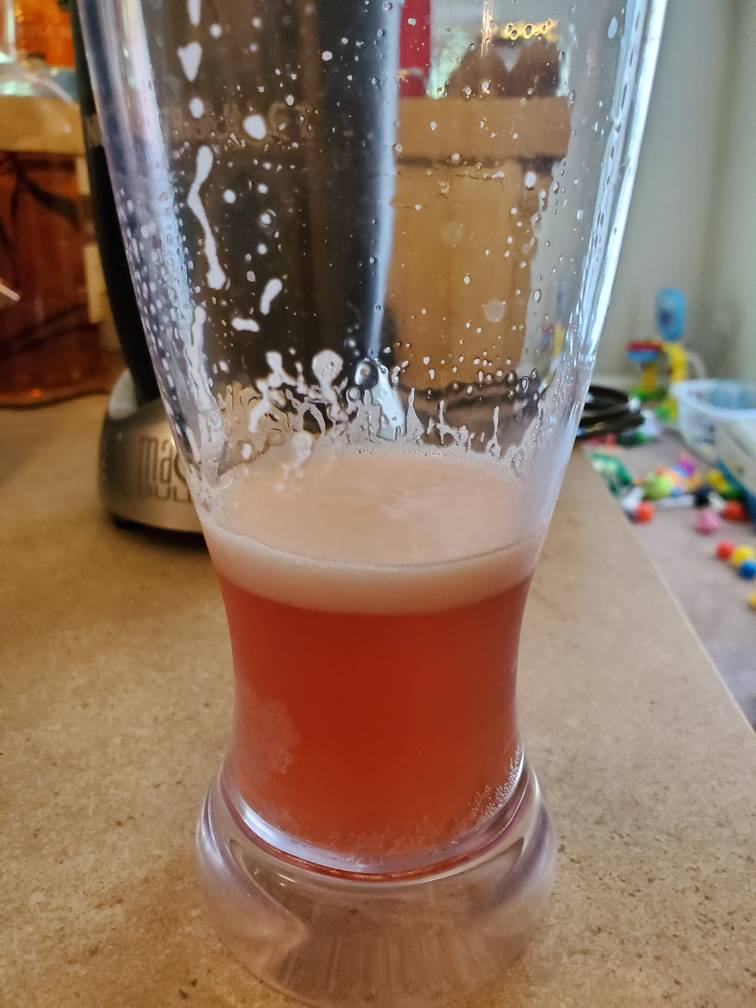

Da Beer.... Pecan Smoked Alt.This is that same keg today. It's ready to dial back.

What did I do today? Nada... Really.

Just looked at the valve and poured a beer. - Pecan Smoked Alt.

View attachment 622124

.This is that same keg today. It's ready to dial back.

What did I do today? Nada... Really.

Just looked at the valve and poured a beer. - Pecan Smoked Alt.

Nice! I never thought of using a standard regulator that way, and totally missed the large knob sticking out under the pressure gauge your last post before you clarified. BTW, a Pecan Smoked Altbier sounds great! Did you smoke your own malt?

Gonefishing

Someday I'll stop procrastinating

Brewed a smash...didn't use enough water so I made a beer that's going to be too hoppy for my tastes I fear.

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Maybe a better picture....

Nice! I never thought of using a standard regulator that way, and totally missed the large knob sticking out under the pressure gauge your last post before you clarified. BTW, a Pecan Smoked Altbier sounds great! Did you smoke your own malt?

Recapping the pieces left to right.

1) 1/4 NPT Brass plug, screwed into the high pressure side. Using Teflon tape.

2) The regulator and gauge.

3) 1/4 NPT to 3/16 Brass hose barb, screwed into the low pressure side. Using Teflon tape.

4) 3/16 Hose about 12" long, attached with hose clamp (on both ends).

5) 3/16 barb to 1/4 Female Flare Swivel.

6) Quick Disconnect ball-lock that has 1/4 flare.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

.

BTW, a Pecan Smoked Altbier sounds great! Did you smoke your own malt?

Sorry missed that. Yeah I smoke my own malt. Also do the roasting and toasting too.

It's a pretty tasty beer. Mild smoke with some home roasted barley. The smoke/roast mix is good. I hoped with 2 oz of Mt Hood. It's nicely bittered. No late addition to mess with the smoke and roasted grains.

This is my grain smoking thread... All the how to is there. I also have roasting in there too. The emphasis is on Smoked Grain.

https://www.homebrewtalk.com/forum/index.php?threads/637254/

Last edited:

Murphys_Law

Well-Known Member

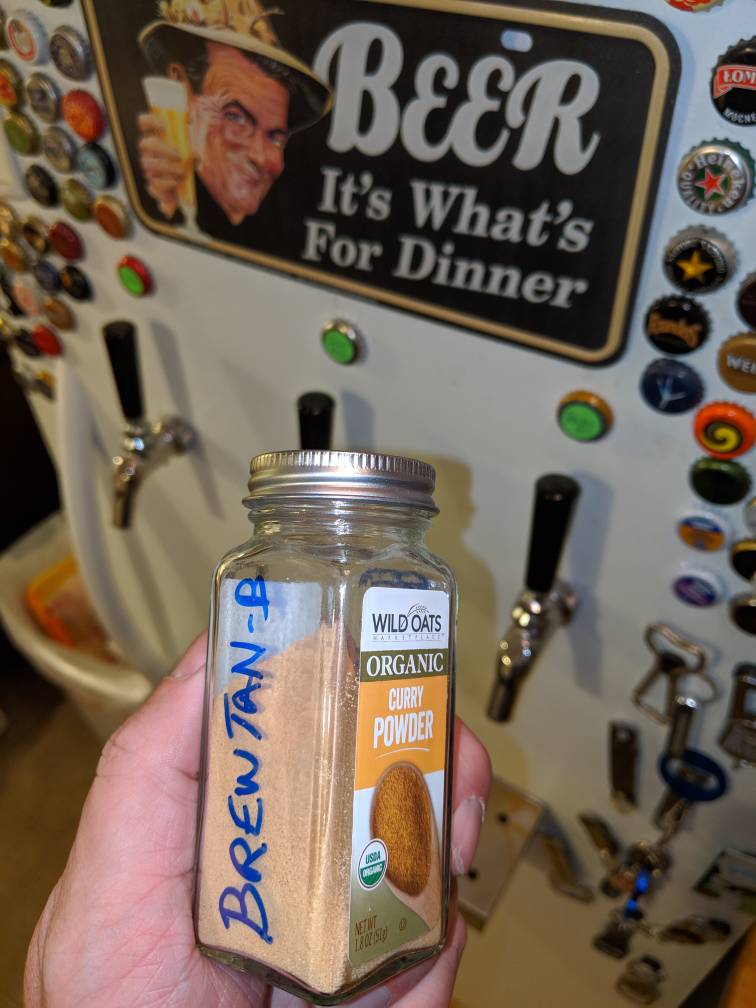

Took inventory of everything - hops, yeast, grain, and even misc things like gypsum, BtB, etc.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

I need to do that!Took inventory of everything - hops, yeast, grain, and even misc things like gypsum, BtB, etc.

Hmm Brewtan-B..... You're one of those guys. LoL.

Shhhh...... Me too.

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Took inventory of everything - hops, yeast, grain, and even misc things like gypsum, BtB, etc.

... Nicely repurposed.

I do something like what you do on the oven cycle. It depends what I want on lovibond. I have a time and temp chart that i use.

I start with 2lbs of pale malt. Measure out distilled water by weight equal to grain weight, less 5% (29oz). Soak it with distilled water for 24 hours refrigerated. Then into the instant pot for 8 hours at 152F. Then I throw it into the oven, in baskets to dry, no heat, only using the oven light on to dry low temp. The oven uses an incandescent light bulb. The temp is roughly 145F with door completely closed. I use a remote meat probe inserted into the grain.

This drying/curing is to keep the diastatic power intact when I make lower 10L-60L Crystal Malt. I still do the same even with 90L - 120L. As you know it requires high temps.

FYI - Heating grains over 210F with greater than 10% moisture hurts the diastatic power.

Screen baskets for drying/curing are shown below with instant pot insert beside them.View attachment 622128

If I could like this a hundred times I would! I will definitely try it next time. Thank you thank you!

Question: when it comes to roasting time, what are the temps & times you use?

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Go back to post #14348... I think where I posted the: Roast'em, Toast'em and Smoke'em If You Got 'em. Thread.If I could like this a hundred times I would! I will definitely try it next time. Thank you thank you!

Question: when it comes to roasting time, what are the temps & times you use?

The first post there has a link to post #22. In post #22 see the link for a google spreadsheet. Open the spreadsheet. Use the section near the bottom. That lists all the lovibond values.

If I could like this a hundred times I would! I will definitely try it next time. Thank you thank you!

Question: when it comes to roasting time, what are the temps & times you use?

And I responded before I saw your link, forgive me. Will definitely give it a look before trying again. Thanks again for the help!

- Joined

- Apr 18, 2006

- Messages

- 16,779

- Reaction score

- 5,916

Np....And I responded before I saw your link, forgive me. Will definitely give it a look before trying again. Thanks again for the help!

And now for What I did for Beer Today; called out "sick" from second job to help husband file extension for taxes. Long story, don't wanna post it here. And tapped the Mosaic Pils that's been carbing, and am in love with it. Huge hop nose and flavor, nothing off, and lighter than the usual Smash I do with these hops. Yeah, I know a lot of people here are "meh" about Mosaic, but I love them in whatever I can stuff them in to; this batch is lighter on malt due to higher pilsner in the grain bill, letting the hops shine through as I intended. It's gonna go fast, and glad I have it on tap now.

Scaled up volume and brewed an azacca pale ale from extract to all grain biab. I have high hopes for it being a staple in my inventory. Fell in love with the extract batches, so here’s to hoping I didn’t screw it up too much!

Racked my first ever sour ale (berliner weisse style) I made to the keg. Used 2 lbs of fresh picked blueberries. Also, picked a 3rd harvest from my comet hop plant. Got 11oz of dried hops from it total now!

Getting 3 cases of bottles ready to bottle condition my Hefe.

Pitched a 3L starter into my 6g batch of Märzen. Swapped two kegs in my kegerator & cleaned two empties. Also cleaned my two flasks.

Pick up some Wheat DME and bottle caps.

histo320

Well-Known Member

Made a starter for a Cream Ale and convinced my wife I need another keg by way of her having try my Maris Otter Amarillo SMaSH.

How'd you do the Blueberries?I checked the carbonation on my blueberry sour ale. I am really digging this. I might make more sours now!View attachment 622682

Since they are in season I went by the local farm and picked some. I used 2 pounds and added water until slightly covered and boiled for 10 minutes then mashed them and let cool to room temp. I added them to the primary fermentation after 5 days and let the beer set for about 15 days in primary.How'd you do the Blueberries?

What was your batch size? About ready to add blueberries to my sour. Just curious. Mine will be about 6gal.Since they are in season I went by the local farm and picked some. I used 2 pounds and added water until slightly covered and boiled for 10 minutes then mashed them and let cool to room temp. I added them to the primary fermentation after 5 days and let the beer set for about 15 days in primary.

Guess I should post something. Sat the corner posts for my brew pub. It'll be small and humble but be nice to have my own spot.

Mine was 5.5. Adding in primary will add around a .5% abv increase alsoWhat was your batch size? About ready to add blueberries to my sour. Just curious. Mine will be about 6gal.

I want to do an outdoor bar at some point to that sounds awesomeGuess I should post something. Sat the corner posts for my brew pub. It'll be small and humble but be nice to have my own spot.

View attachment 622713

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

Latest posts

-

-

-

-

-

The Dysfunctional-Palooza Obnoxious Masshole BS Thread

- Latest: Hoppy2bmerry

-

-

-

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)