Drinking Sensibly

Well-Known Member

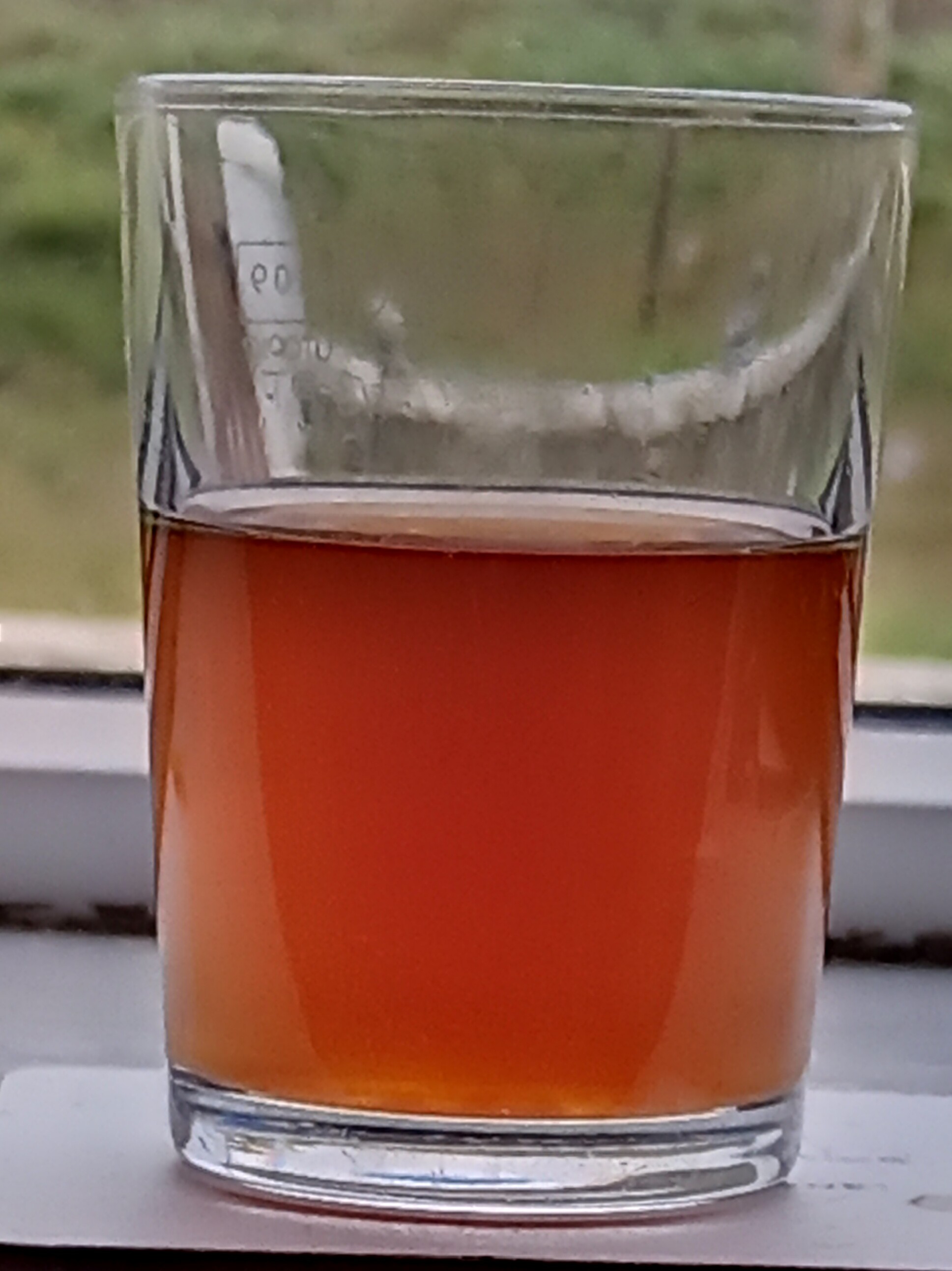

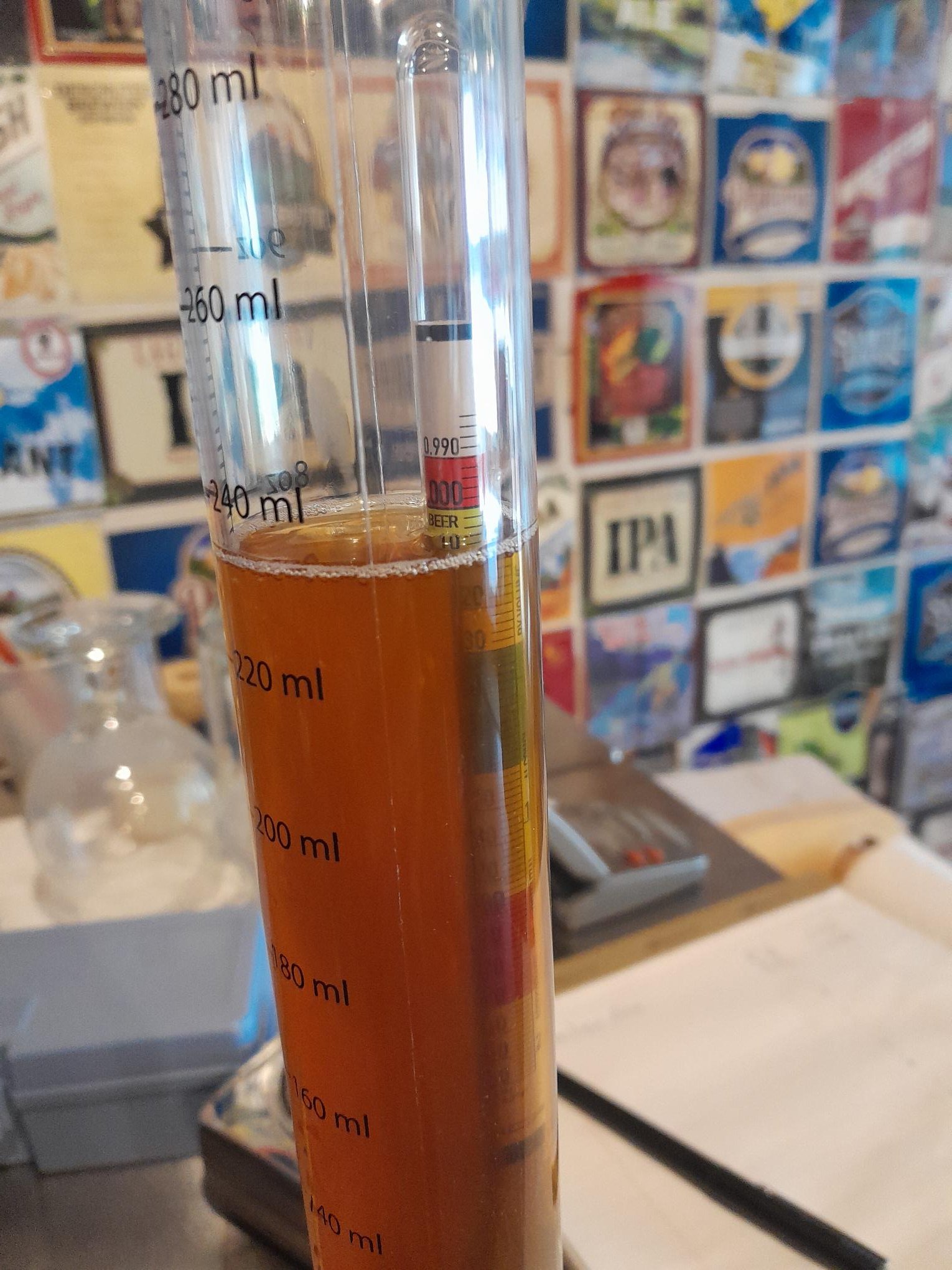

Filled 41 half-litre bottles with Czech style lager.

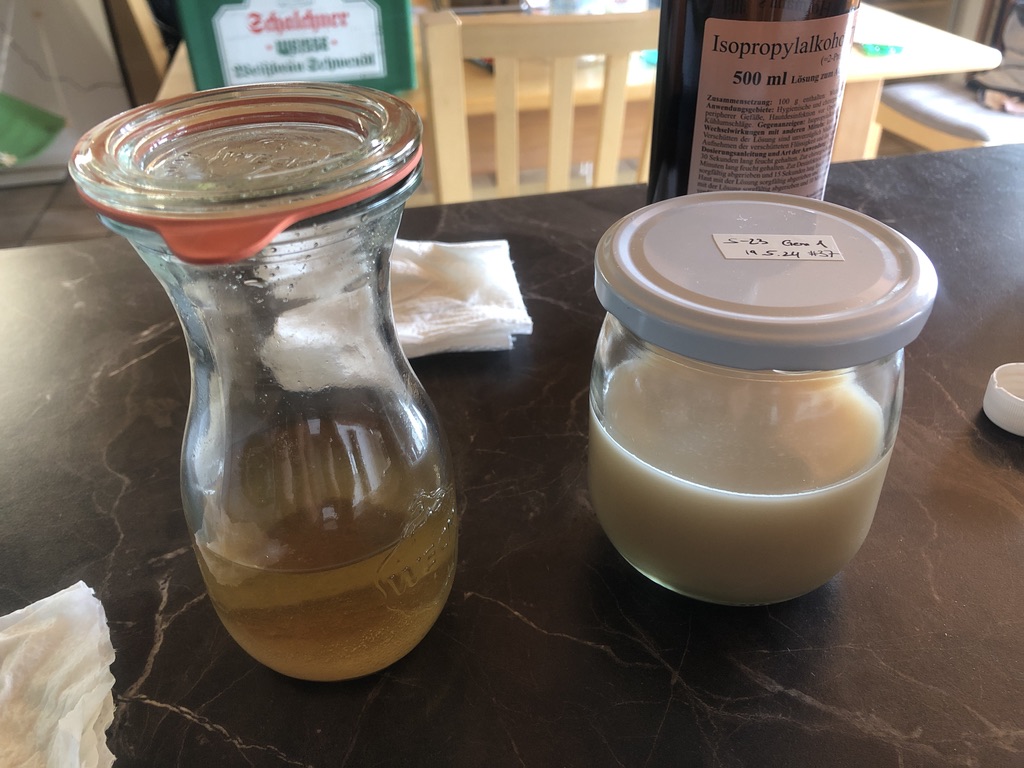

Got everything ready for brewing an Altbier tomorrow.

Last edited:

Filled 41 half-litre bottles with Czech style lager.

Got everything ready for brewing an Altbier tomorrow.

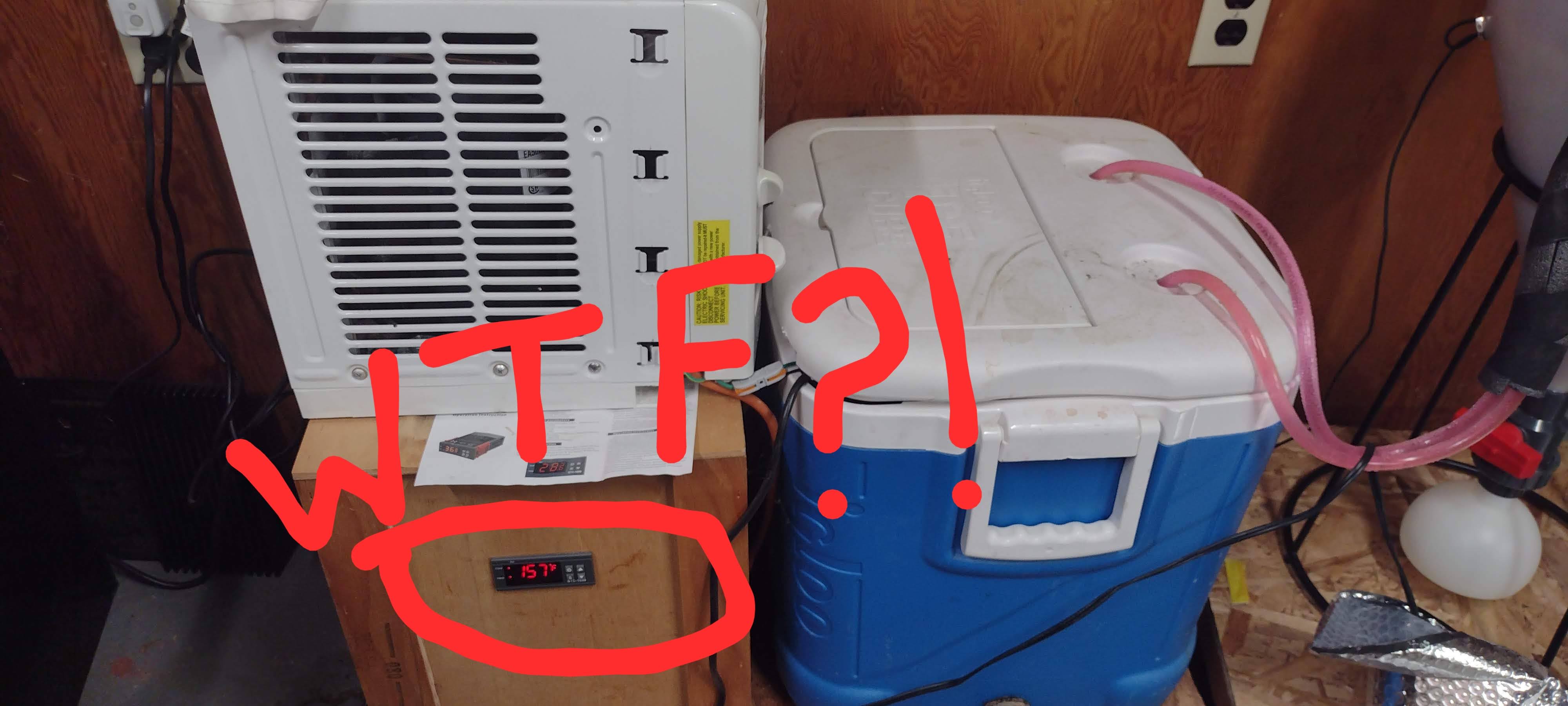

Yeah things happen... but it's what happens when you buy off Amazon for 1/2 the cost of the big bois.Really appreciate the clear instructions and the time you put into doing that, I have this bookmarked. Thank you!

I've been brewing for three decades, so I certainly know what it feels like to find out your holy grail parts aren't what you thought they would be. It's a running joke, really.

The important thing is that you made them work. That's proper homebrewing, sir!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Oh boy, that's never a fun one. I feel for you, sir.cleaned up a big blow out of yeast. Had half inch silicone blow-off tube....but the bung either wasn't pushed in tight enough or got forced out by the kräusen...lot of overflow in the ferm fridge...

at least I know the yeast is healthy

found out what it was...one of my airlocks (but not the other two) has a little feature at the bottom that maybe is there to prevent debris movement...well it clogged. Cut it off and sanded it down to prevent future mishapsOh boy, that's never a fun one. I feel for you, sir.