Averted what might have been a major disaster this afternoon. Moved my blonde ale from the ferment fridge to the kegerator, as the ferment fridge wasn't cooling fast enough. Placed my hand on the center part of the ferment fridge when I stood up, and almost burned myself. Ouch! Quick check with the temperature gun showed 160°!!! Holy crap! So I pulled the fridge out, took off the back panel, and found the condenser fan motor to be burned out; one of the fan blades broke off and jammed it. Surprised the compressor was still working, it was so hot. Put a small fan back there to cool everything down and fridge is unplugged for the duration. Amazingly, Amazon has the correct part number in stock (have to order fan and blade separately, the fan blade attaches with a ridiculously complicated compression thingie that breaks easily when you try to take the blade off) and is costing me about $110. Will be here on Sunday, which is putting the kibosh on brewday tomorrow; but if I can fix my precious ferment fridge, I'm willing to wait. It already has an aftermarket 3-in-1 capacitor doomahatchie for when the compressor starter capacitor thing went out (don't you guys love it when I talk all tecknical and stuff).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It already has an aftermarket 3-in-1 capacitor doomahatchie for when the compressor starter capacitor thing went out

Stop! You're getting me all excited here!

Good for you for diagnosing and taking on the repair

Cheers!

Yes I already posted here today, but I'm sitting here tonight with my brain sploding. Bit of backstory; for the last several years (with a few exceptions, as when I take the brewery on the road) I've been using water from my oh-so-convenient water heater for my strike. Have gotten some cr*p for that from a few circles, but it gets me to strike temp fast and I have made many wonderful (some award-winning) beers with it. Water heater is less than 5 years old, water from it tastes good. A few brews back I got it into my head that I needed to start using cold water from the kitchen tap for brewing; had to be better. Well.....NOT. The last few beers have turned out very dry, even with higher mash temperatures (152-154) than I usually use. Even making some adjustments with what I had available didn't make a difference, up to and including 2tsp of lactic acid. Preboil gravities were several points lower than beers made with the hot water. The PF lager I'm currently sipping on is technically a good beer, but way dryer than I like. After some thinking, and much reading of previous notes, it's the water. No other changes were made to the process, or to proven recipes I've done many times before.

I'm not just saying this because these are my beers, that I tend to like a lot more than what I can get commercially; I like a fuller-bodied, maybe a tad sweeter, beer. Not sweet like sugar or cloyingly sweet like molasses, but just a tad more sweetness on the tongue. You'd think I'd get that by softening the cold water, right? Well, no. I do not know exactly what it is, but the beers I make with water from the heater are just, well, better. I'm sitting here tonight, next to my soon-to-be-repaired ferment fridge, repeating ITS THE WATER DAMMIT. I still have two in the kegerator from before I changed my water, and they are MUCH better (even the 2-month-old Wit) than the lager I have in my glass right now. Yes, lager will improve with time, but time will not change the dryness of it very much.

Damn.

I'm not just saying this because these are my beers, that I tend to like a lot more than what I can get commercially; I like a fuller-bodied, maybe a tad sweeter, beer. Not sweet like sugar or cloyingly sweet like molasses, but just a tad more sweetness on the tongue. You'd think I'd get that by softening the cold water, right? Well, no. I do not know exactly what it is, but the beers I make with water from the heater are just, well, better. I'm sitting here tonight, next to my soon-to-be-repaired ferment fridge, repeating ITS THE WATER DAMMIT. I still have two in the kegerator from before I changed my water, and they are MUCH better (even the 2-month-old Wit) than the lager I have in my glass right now. Yes, lager will improve with time, but time will not change the dryness of it very much.

Damn.

- Joined

- Sep 6, 2021

- Messages

- 583

- Reaction score

- 2,515

That's really interesting; unfortunate for your last couple brews, but genuinely interesting. Another totally unexpected temperature-related variable to take into account.Yes I already posted here today, but I'm sitting here tonight with my brain sploding. Bit of backstory; for the last several years (with a few exceptions, as when I take the brewery on the road) I've been using water from my oh-so-convenient water heater for my strike. Have gotten some cr*p for that from a few circles, but it gets me to strike temp fast and I have made many wonderful (some award-winning) beers with it. Water heater is less than 5 years old, water from it tastes good. A few brews back I got it into my head that I needed to start using cold water from the kitchen tap for brewing; had to be better. Well.....NOT. The last few beers have turned out very dry, even with higher mash temperatures (152-154) than I usually use. Even making some adjustments with what I had available didn't make a difference, up to and including 2tsp of lactic acid. Preboil gravities were several points lower than beers made with the hot water. The PF lager I'm currently sipping on is technically a good beer, but way dryer than I like. After some thinking, and much reading of previous notes, it's the water. No other changes were made to the process, or to proven recipes I've done many times before.

I'm not just saying this because these are my beers, that I tend to like a lot more than what I can get commercially; I like a fuller-bodied, maybe a tad sweeter, beer. Not sweet like sugar or cloyingly sweet like molasses, but just a tad more sweetness on the tongue. You'd think I'd get that by softening the cold water, right? Well, no. I do not know exactly what it is, but the beers I make with water from the heater are just, well, better. I'm sitting here tonight, next to my soon-to-be-repaired ferment fridge, repeating ITS THE WATER DAMMIT. I still have two in the kegerator from before I changed my water, and they are MUCH better (even the 2-month-old Wit) than the lager I have in my glass right now. Yes, lager will improve with time, but time will not change the dryness of it very much.

Damn.

Emptied out the mulch bin onto the hops and grapevines. Gonna be a stinky few days, but it's worth it!

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

Water heaters get mineral build up over time which could make that water softer(less calcium) compared to straight from the tap. They have cheap water test kits for aquariums that would give you a basic idea on how the two waters differ.Yes I already posted here today, but I'm sitting here tonight with my brain sploding. Bit of backstory; for the last several years (with a few exceptions, as when I take the brewery on the road) I've been using water from my oh-so-convenient water heater for my strike. Have gotten some cr*p for that from a few circles, but it gets me to strike temp fast and I have made many wonderful (some award-winning) beers with it. Water heater is less than 5 years old, water from it tastes good. A few brews back I got it into my head that I needed to start using cold water from the kitchen tap for brewing; had to be better. Well.....NOT. The last few beers have turned out very dry, even with higher mash temperatures (152-154) than I usually use. Even making some adjustments with what I had available didn't make a difference, up to and including 2tsp of lactic acid. Preboil gravities were several points lower than beers made with the hot water. The PF lager I'm currently sipping on is technically a good beer, but way dryer than I like. After some thinking, and much reading of previous notes, it's the water. No other changes were made to the process, or to proven recipes I've done many times before.

I'm not just saying this because these are my beers, that I tend to like a lot more than what I can get commercially; I like a fuller-bodied, maybe a tad sweeter, beer. Not sweet like sugar or cloyingly sweet like molasses, but just a tad more sweetness on the tongue. You'd think I'd get that by softening the cold water, right? Well, no. I do not know exactly what it is, but the beers I make with water from the heater are just, well, better. I'm sitting here tonight, next to my soon-to-be-repaired ferment fridge, repeating ITS THE WATER DAMMIT. I still have two in the kegerator from before I changed my water, and they are MUCH better (even the 2-month-old Wit) than the lager I have in my glass right now. Yes, lager will improve with time, but time will not change the dryness of it very much.

Damn.

Where I live the source of our water changes seasonally so I went with building my water from RO to keep thing consistent.

Swung by the LHBS. Picked up malted and torrified wheats, Vienna, Mittlefruh, and some WLP066. Brewing up a wheatwine, but that's a different thread.

Since I was in St. Louis Park for a doc appt a couple days ago I decided to stop in to Midwest Supplies afterward for a few items, including a bottling bucket. The old one is getting kind of grungy. Didn't buy a spigot as I have a couple extras in a drawer at home. Got home and found that the hole in the bucket is 7/8" but my spigot needs a 1" hole. Good thing I have a set of Forstner bits. Had to get the bucket ready because today was bottling day. I like the new bucket better, as it is more translucent and I can actually watch the beer level as I go.

Bottled 10 gallons of IPA which was split between two Brew Buckets. Just a basic IPA, using some leftover grain and hops. Pitched US-05. On brew day I racked a little under 6 gallons of wort into each. After fermentation was complete I dry hopped with 4 oz. into each fermenter. I used to use dry hop bags but this time decided to let the pellets free-range in hopes of getting better aroma. I was able to rack just under 5 gallons from each, as I was left with about a gallon of trub/hops residue in each Brew Bucket. Don't care and I expected as much. Ended up with 95 12oz long necks. I carbed a little on the low side in case I get some hop creep. Had better than expected efficiency on brew day and OG was 1.070; FG 1.011, so almost 8% ABV!

I was getting things ready for cleanup in the downstairs utility room. My wife walked in, saw what was in the bottom of the Brew Buckets and almost horked. It didn't help when I suggested we have it on biscuits tomorrow morning.

Bottled 10 gallons of IPA which was split between two Brew Buckets. Just a basic IPA, using some leftover grain and hops. Pitched US-05. On brew day I racked a little under 6 gallons of wort into each. After fermentation was complete I dry hopped with 4 oz. into each fermenter. I used to use dry hop bags but this time decided to let the pellets free-range in hopes of getting better aroma. I was able to rack just under 5 gallons from each, as I was left with about a gallon of trub/hops residue in each Brew Bucket. Don't care and I expected as much. Ended up with 95 12oz long necks. I carbed a little on the low side in case I get some hop creep. Had better than expected efficiency on brew day and OG was 1.070; FG 1.011, so almost 8% ABV!

I was getting things ready for cleanup in the downstairs utility room. My wife walked in, saw what was in the bottom of the Brew Buckets and almost horked. It didn't help when I suggested we have it on biscuits tomorrow morning.

WestMichiganSteelheader

Well-Known Member

Damnit, I dropped one of my favorite pint glasses. What is even worse, it was full of beer.

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

Last post here this weekend, I swear. Got the parts for the ferment fridge, and I'm a little annoyed. They sent the motor assembly in a sturdy box, and the fan blade in one of those flimsy plastic things; yes it had a blade broken off on arrival. Would take two days to get another one here, so I just used some superglue and strong tape to put it back together. Just installed it about 30 minutes ago, and fridge is working perfectly again. Yay!!! I didn't let it run very long, just long enough to make sure it started cooling and the fan was spinning. True test will be when the current beer in there is ready for crashing next weekend. Despite all odds I went ahead and brewed yesterday, had a fan running behind the fridge in case it needed to turn on; this one is fermenting at 71, so it maybe came on twice.

Transferred latest NEIPA to dry hop keg and did a FG sample. FG was right on and transfer was the easiest so far. The sample tasted better than the last version and I loved the last one. I did better keeping mash temp where I wanted this time and I think that ended up helping the FG.

Also tasted the WC IPA that has been carbbing a few days and it tasted great dispute needing a bit more time to carbonate.

Heading to Mexico for work for a few days this week but when I get back I should finally have both a hazy and WC on tap at the same time or at least shortly after

Also tasted the WC IPA that has been carbbing a few days and it tasted great dispute needing a bit more time to carbonate.

Heading to Mexico for work for a few days this week but when I get back I should finally have both a hazy and WC on tap at the same time or at least shortly after

Pitched the yeast in 9g of Saison from a group brew day with Lallemand Belle Saison after setting up my new Inkbird 308 to replace my 14 year old Ranco two stage controller.

BrewMan13

Whole Nother Level Brewing

Mercifully kicked my terrible hefeweizen yesterday (luckily it was only a half batch). This freed up a line to put on our club big brew day collab with the warbler brewery: an ESB.

I’ve done that with my first cheapo stick. How are you cleaning the heating element?First time mashing with a sous-vide which I already use for cooking.

OMG, makes life so easy hitting and maintaining mash temp. GAMECHANGER! I didn't do the boil with it, but regular electric stove, but maybe next time.

I hate it when that happens, and I’m glad you were outside at the time. Yesterday I was getting ready to install a screw on swing top to a vintage Bluepoint 1/2 gallon growler and it crashed to the tile floor and glass shards almost made it to the living room. Of course I wasn’t wearing shoes at the time. After the cleaning was done I successfully installed in on my other vintage growler.View attachment 822768

Damnit, I dropped one of my favorite pint glasses. What is even worse, it was full of beer.

Instead of making another post, and now that I’m caught up, I’ve done a few things for beer in the past week and a half. The 9th and 10th was my club’s competition. I did some stewarding all 3 sessions. I was the prize coordinator, and thankful for all the helping hands unpacking and packing up at the end. I managed to earn 2 ribbons and a couple prizes for myself. Today I’m making space to bottle some mead and get a new one started, I also plan to add apricot purée to my apricot wheat that needs more flavor. Later HBC meets, at a brewery I haven’t visited in a while.

Last edited:

seanjwalker1

Dunkel Vater

- Joined

- Sep 30, 2015

- Messages

- 1,722

- Reaction score

- 5,203

Even better, for those of us still using plastic coolers, how do you stop it from melting the side or bottom of said plastic mash tun ?I’ve done that with my first cheapo stick. How are you cleaning the heating element?

I heat sparge water to 170F in food grade plastic no problem.Even better, for those of us still using plastic coolers, how do you stop it from melting the side or bottom of said plastic mash tun ?

- Joined

- Apr 2, 2021

- Messages

- 14

- Reaction score

- 44

Checked on my amber ale that went into the fermentation fridge yesterday, and discovered an empty airlock. On closer inspection, it had a big crack in the side of it. As soon as I replaced it, the new airlock started bubbling happily, so I'm assuming (hoping) no harm, no foul.

bellhp

Well-Known Member

Yeah , no worries , it'll be fine.new airlock started bubbling happily

Yesterday I bottled the beer I brewed before I went offshore for three weeks.

5 gallons of "Dobby the house bitter"

5 gallons of "I just cut a big one" ( Low ABV Vienna lager , my experimental lawn mowing beer) .

Going back offshore tonight ... deciding if I've got time to brew another batch before I have to go .

Not completely beer related, but gave me the warm fuzzies like a good beer does. A friend at work has recently gotten into cross stitch, and was lamenting today that she didn't have a hoop or a frame. Remembered the big wooden frame that I've had sitting in a box for about 20 years and offered it, if I still had all the parts. Came home to find all but one knob intact (can replace with a simple wingnut from the hardware store), then had to figure out how to put it together. Did I mention this thing is well over 20 years old? Of COURSE youtube had a video on how to assemble it. She's ecstatic, I've emptied one of the many storage tubs in the garage that the husband is always b*tching about, everyone is happy. Oh look, beer!

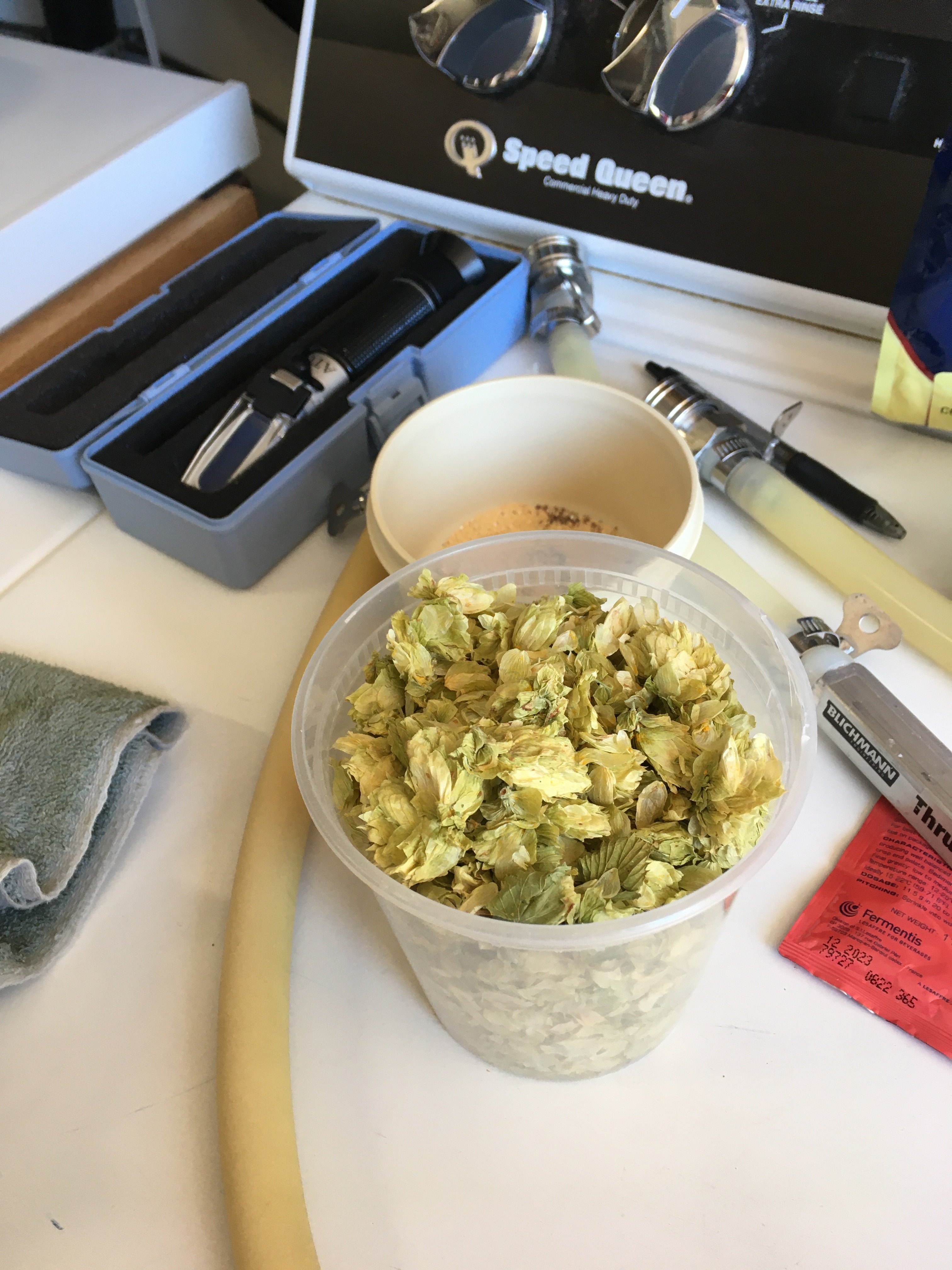

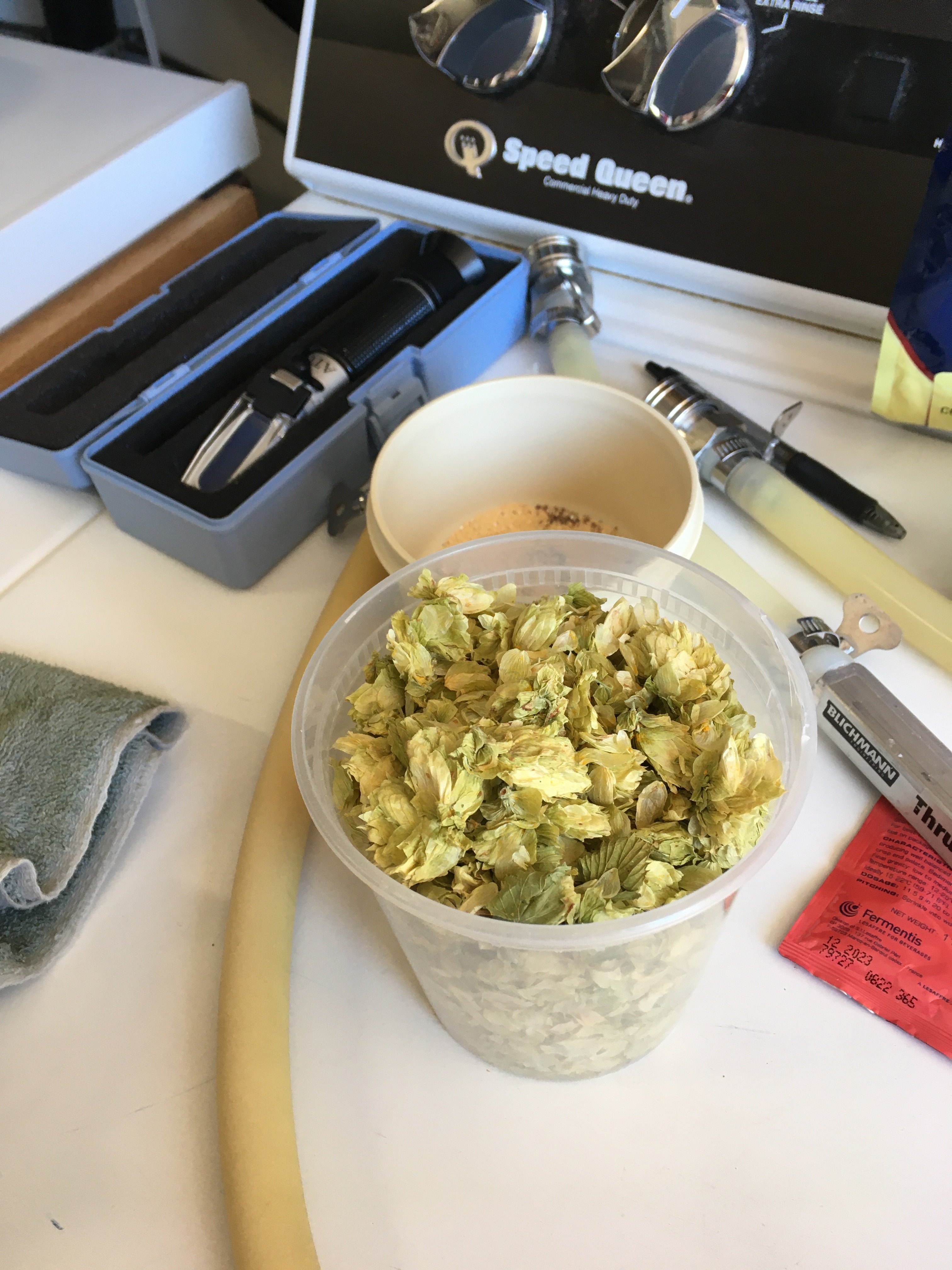

Yesterday made a Pale Ale with whole leaf Cascade.

Put an ABC Cork wheat ale no boil kit in the fv. Used 2# of Briess wheat dme instead of the 1 kilo of corn sugar and went with 4.5 gallons instead of 6. Kits are on sale for $10 so figured why not.

BrewMan13

Whole Nother Level Brewing

2 days ago I made a maltodextrin solution so @Dgallo and I can thicken up our barrel aged imperial stout.

Last night cleaned a keg and line, and put the maibock on. Going to go super slow with this one as I wouldn't mind it "lagering" a bit more, but didn't want to leave the line open if possible.

Last night cleaned a keg and line, and put the maibock on. Going to go super slow with this one as I wouldn't mind it "lagering" a bit more, but didn't want to leave the line open if possible.

Using Maltodextrin is one of the techniques I need to do, since I am not adding lactose to any of my long-aged beers. How did it work out for you, or how has it worked in the past?2 days ago I made a maltodextrin solution so @Dgallo and I can thicken up our barrel aged imperial stout.

Last night cleaned a keg and line, and put the maibock on. Going to go super slow with this one as I wouldn't mind it "lagering" a bit more, but didn't want to leave the line open if possible.

BrewMan13

Whole Nother Level Brewing

I'll let you know tomorrow. I made it ahead of time since he doesn't generally have a lot of free time, and we have to blend it and rack the beer as quickly as reasonably possible, so I wanted it to be ready at a moments notice. I actually used half a gallon of dry stout as the liquid to dilute the main beer as little as possible. We used 3 lbs for about 10 gallons. Way higher than normal recs, but this is a BIG beer that attenuated surprisingly well, so want to get some of that body back.Using Maltodextrin is one of the techniques I need to do, since I am not adding lactose to any of my long-aged beers. How did it work out for you, or how has it worked in the past?

Dgallo

Instagram: bantam_brews

after 7.5 months in a bourbon conditioned fresh American oak barrel, @BrewMan13 and my 14.1% imperial stout have been racked to kegs.

Dgallo

Instagram: bantam_brews

Today 2 of the 3 are out with me to take a rainy walk to collect wild black raspberries (black caps) for this years rendition of my wild ale “forager”

Maxie is currently eating more than he’s putting in the bucket lol

Maxie is currently eating more than he’s putting in the bucket lol

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)